What is Electronics Manufacturing Process in Production?

The electronics manufacturing process in production refers to the steps that makers follow to turn ideas into real electronic gadgets. It includes many phases like planning, gathering parts, putting things together, checking for issues, building the outer case, ensuring quality, and boxing up the final product.

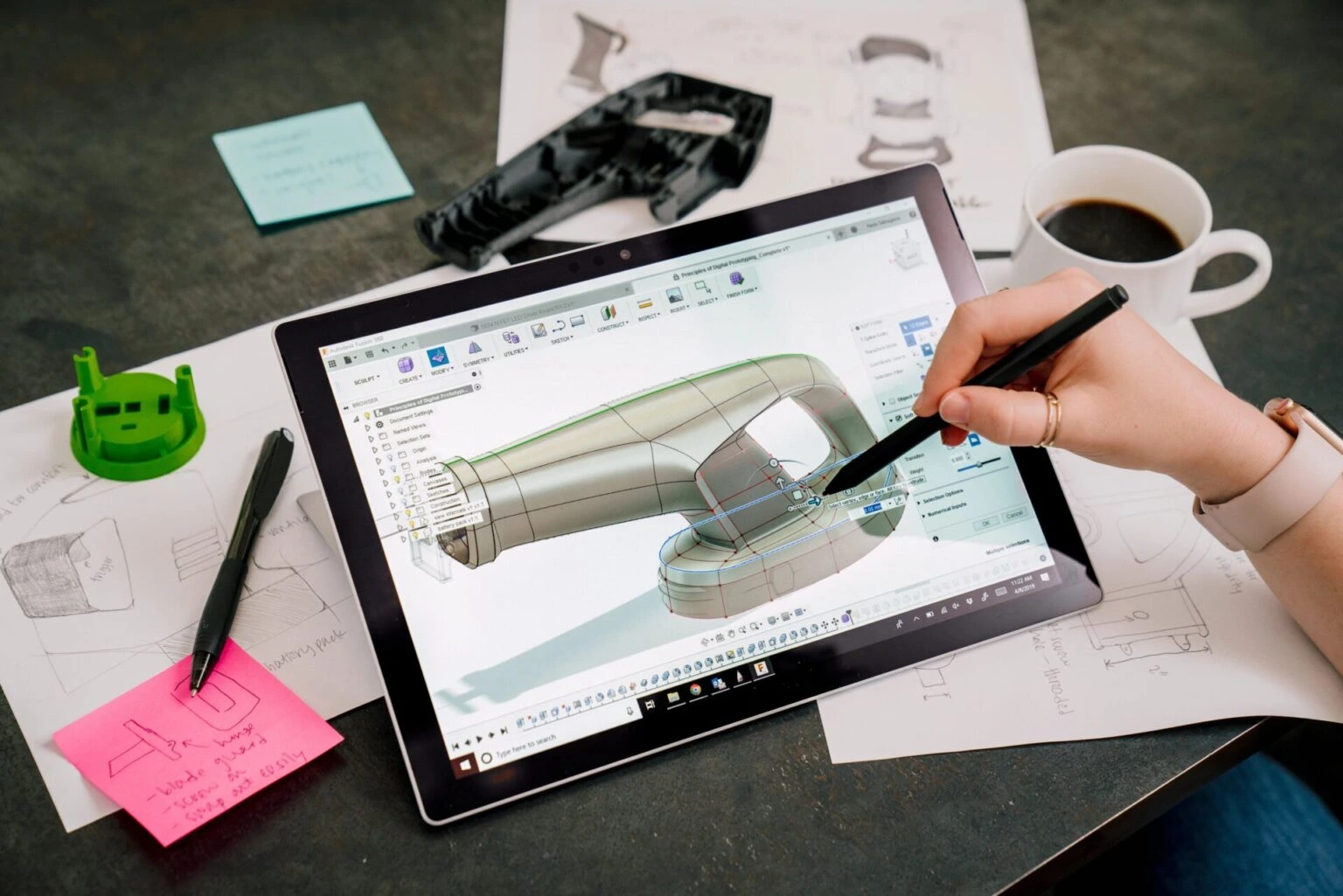

The first task is to sketch out the electronic item and build a sample. This means coming up with the idea, drawing the wiring, and making a test version to tweak and improve. Once it’s ready, makers start collecting needed bits like integrated circuits and capacitors during component sourcing.

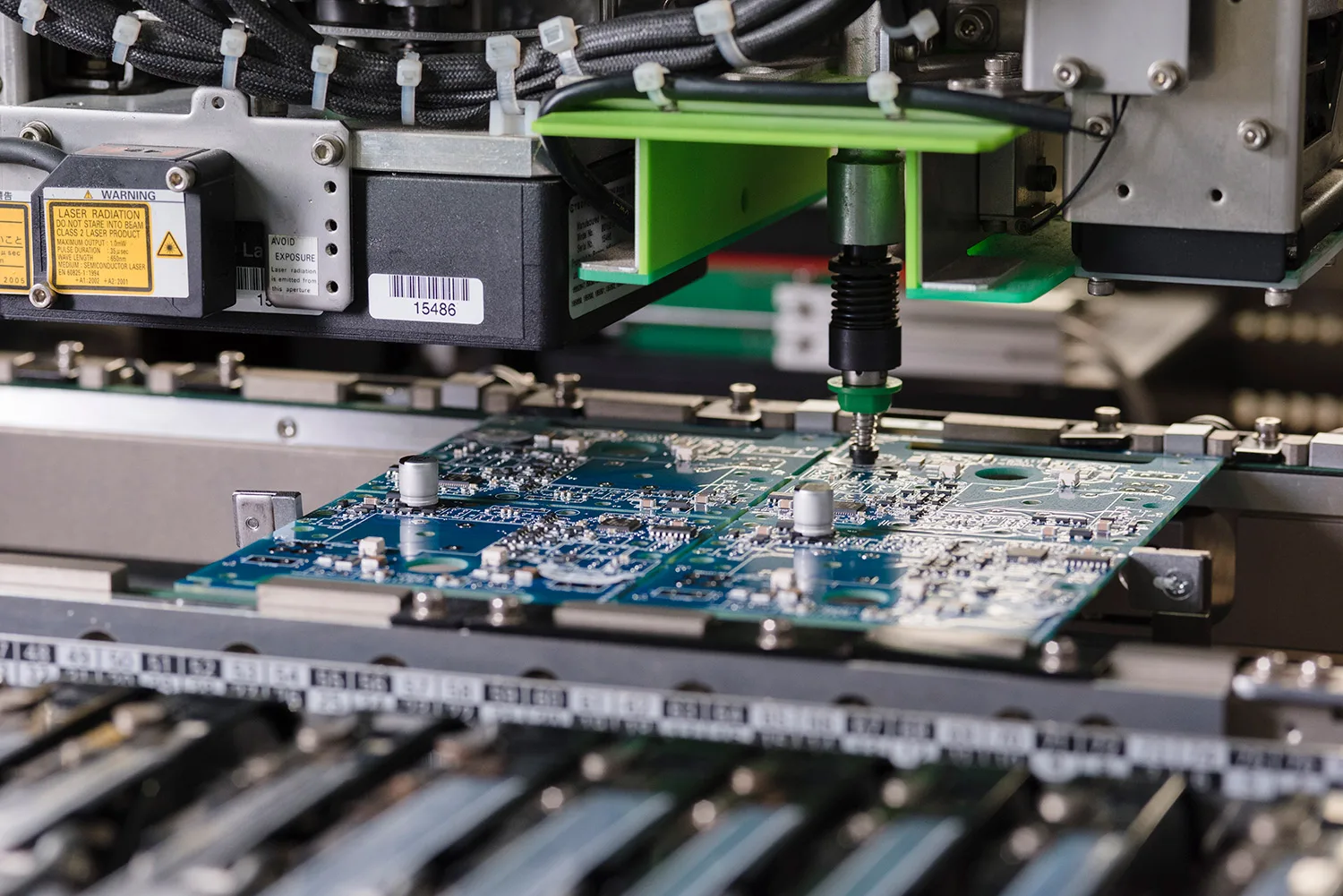

Then, it’s time for PCB assembly. Here, parts are attached to printed circuit boards using a method called Surface Mount Technology (SMT). After that, the item goes through strict checks to make sure it works well, performs as expected, and meets high standards.

The outer shell or casing of the product is crafted to shield the inside parts. During final assembly, everything is put together inside this casing. Thorough quality control steps are used all through the making process. At the end, the products are packed with extras and sent out.

Eco-Friendly Initiatives

More and more companies see the need to cut down on harm to nature. This has led to a bigger focus on using earth-friendly ways in making electronic items. Some places now rely on solar power to lower pollution and save resources.

A lot of firms are working hard to be green manufacturing businesses, choosing methods that are kind to the planet. These efforts not only help nature but also match what buyers want in terms of sustainable electronics.

Preparing Your Workspace for PCB Handling

Printed circuit board assemblies, or PCBs, are slim boards made from different stuff. They hold and link electronic parts. The PCB assembly step is a key and careful part of creating electronic products.

To keep things in good shape:

- Keep the space neat and clear of mess to protect PCB quality.

- Put covers on sharp corners of work areas.

- Use mats or tables that stop static if you can.

- Wear gloves to avoid dirt or damage.

- Don’t touch the open wiring.

Doing these things helps keep PCBs working well for their whole life.

What is PCB Layout Design for Manufacturability?

Design for circuit board manufacturability (DFM) means setting up the PCB layout in a way that avoids troubles when building and assembling it.

Important points to think about are:

- Component placement – Place parts so they don’t mess with each other’s signals.

- Routing density – Find a good balance between saving space and making it easy to build.

- Thermal management – Watch out for heat differences that might make parts stretch or shrink unevenly.

- Signal integrity – Keep fast signals clear and strong.

Doing DFM right cuts costs by spotting problems early in the planning stage.

Electronics Manufacturing Outsourcing

Outsourcing comes with several perks:

- By teaming up with contract manufacturers or electronic manufacturing services (EMS) providers, businesses can save money through bulk production. This also lowers big spending and reduces extra costs tied to having their own factories.

- These contract makers and EMS providers have the know-how, setup, and skilled workers to manage tough production jobs smoothly.

- Scalability: Contract manufacturers can easily change production amounts to match shifting market needs.

- Access to technology: These providers often spend on the latest tools and machines for making things.

Outsourcing lets companies focus on creating new ideas while trusted partners handle production well.

Trends in the Consumer Electronics Industry

The world of consumer electronics manufacturing keeps changing. New gadgets and tools come out while older ones fade away.

Some hot trends right now are:

- Smart and connected gadgets – From smartphones, people want easy and smooth links.

- Artificial intelligence (AI) integration – AI features that make user experiences more personal.

- Wearable technology – Things like fitness trackers are growing steadily.

- 5G rollout making devices connect better.

- More want for eco-friendly items.

- Foldable screens becoming popular.

Makers need to keep up fast or they might fall behind.

What Are the Challenges Faced in the Electronics Manufacturing Process?

If you’re not careful, electronic parts can quickly become old or get damaged. The field faces many hurdles such as:

- Fast-changing tech – Firms must keep updating their goods, which takes a lot of time and money.

- Short life spans causing e-waste.

- Strong competition worldwide.

- Low prices squeezing profits.

- Shortages of raw stuff like chips.

- Rules and laws that are hard to follow.

- Buyers changing what they like.

- Bad economy hurting sales.

- Social media shaping how people see brands.

- Stealing of ideas when outsourcing.

- Supply chain issues causing holdups.

- Data safety risks with IoT gadgets.

- Worker issues about job conditions.

- Hard entry into new markets.

- Pressure to be sustainable from rules and buyers.

- Duty to handle old products at end of life.

- High costs for warranties.

- Fake products hurting brand trust.

- Recalls needing tracking systems.

Every problem needs careful planning in areas like creating, supply chains, selling, and following rules.

Streamline Your Electronics Manufacturing Process with Silkbridge

At Silkbridge, we’re proud of blending British creativity with Chinese making skills. Based in Guangdong Province since 2014, Silkbridge gives a complete service—from planning to final putting together—all in one place.

Our skills cover:

- Plastic Injection Mold Making with over 30 CNC machines.

- Plastic Injection Parts Production using 100 top-notch injection molding machines from 180 tons to 1200 tons.

- PCB Development with high-end tools from top world brands.

- Electronic Product Assembly done in safe, controlled spaces.

We also provide shipping help with DDP options by air, sea, or train, based on cost or speed needs.

Silkbridge has sent products sold around the world through Walmart, Costco, and Amazon—showing we’re a reliable partner for top-quality electronics manufacturing work.

For more information on developing and producing a new part or product, please contact Silkbridge on our business WhatsApp account https://wa.me/8618122838771 or call us on +86 8618122838771.

FAQ

What does the electronics manufacturing process involve?

It covers many steps like planning, getting parts, assembling, testing, making the outer case, checking quality, and packing.

Why is eco-friendliness important in electronics?

Lots of firms are trying to be green manufacturing businesses, helping make production kinder to the earth.

How do I safely handle PCBs?

Use static-free mats or tables if you can, wear gloves, and don’t touch the wiring directly.

What is DFM?

Design for circuit board manufacturability (DFM) is about setting up the PCB layout plan.

Why outsource electronics production?

Outsourcing helps manage making costs better while giving room to grow and access to new tech.