In the fast-changing world of consumer goods production, plastic injection molding stays a key method for making large numbers of accurately built parts. From everyday home items to new gadgets, injection molded plastics support many different uses that fit changing customer needs. But to keep a strong edge in the market, companies must follow important industry changes closely. These developments affect choices in materials and how products are made. They also change the way manufacturers provide real value in consumer markets worth more than $600 billion worldwide.

For brands handling these shifts, working with skilled injection molding suppliers like Silkbridge can open up custom solutions. Silkbridge is a Guangdong-based factory that combines British design creativity with Chinese production strength. This partnership leads to high-quality, easy-to-scale results.

Eco-Consciousness: Prioritizing Sustainable Materials and Processes

Customer choices have clearly moved toward products that are kind to the environment. Surveys show that about 42% of buyers in major markets now look for eco-friendly choices. This change pushes manufacturers to add sustainability into plastic injection molding steps. It matters most for consumer items like packaging, toys, and household goods where people notice recyclability easily.

Leading this movement are biodegradable and bio-based resins. These options work well instead of usual petroleum-based plastics and keep the same level of performance. Popular examples include:

- Thermoplastic Starch-based Plastics (TPS): Made from natural sources like corn starch, TPS works great for soft, compostable packaging in food and drinks. It helps cut down waste in landfills.

- Polyhydroxyalkanoates (PHA): These natural polymers come from bacterial fermentation. They suit sturdy consumer goods such as disposable cutlery or personal care products. PHA breaks down completely even in ocean water.

- Polylactic Acid (PLA): Created from fermented plant starches, PLA fits firm uses like toy parts or storage boxes. It offers clear looks and good strength, and it composts at home.

- Polybutylene Succinate (PBS): This flexible polyester comes from succinic acid. People use it for soft films and bottles. PBS balances easy breakdown with resistance to heat.

- Polycaprolactone (PCL): A low-melting biopolymer for adhesives and coatings in consumer electronics housings. It makes recycling simpler.

These resins copy the strength and feel of common materials like polypropylene (PP) or acrylonitrile butadiene styrene (ABS). Yet their green benefits meet rising rules, such as the EU’s goal for circular economies by 2050.

Some problems still exist. For example, lower strength in high moisture or heat during molding can cause warping or breaking. Manufacturers fix this by adding helpful fillers like calcium carbonate or natural fibers. These additions build better structure and keep biodegradability intact.

Silkbridge, for example, uses recycled resins along with these bio-options. They produce over 30 million parts each year. This approach brings eco-friendly results for client projects in toys and household products. Their choices of PP, ABS, polycarbonate (PC), and recycled blends follow global rules like EN71 for toys. It supports safety and sustainability.

Energy-saving molding methods make this trend even stronger. Factories shorten cycle times and choose low-emission machines. As a result, they lower their carbon footprint. This step matters for consumer brands that want certification under plans like ISO 14001. In the end, eco-consciousness turns injection molding from a simple cost into a clear advantage. It helps create consumer applications that connect with people who care about the planet.

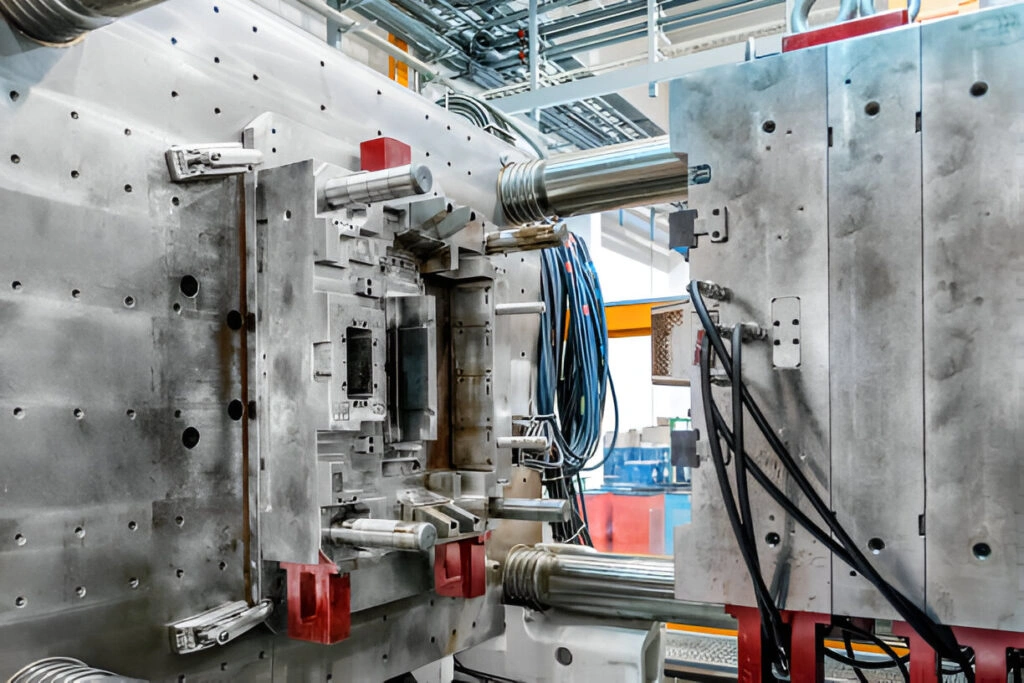

2. Industrial Robotics: Enhancing Precision and Efficiency in Production

Adding industrial robotics to plastic injection molding solves ongoing worker shortages. It also improves product quality and speed. These improvements are vital for consumer markets that need quick updates and custom designs. Experts predict millions of open manufacturing jobs by 2030. So automation becomes a smart must-have choice. Factories can grow output without needing many more workers.

Robotic systems with artificial intelligence (AI) and sensors handle repeated jobs well. They manage part insertion, demolding, and quality checks smoothly. For consumer uses, this means perfect results on tricky shapes. Examples include multi-material overmolding for comfortable toy handles or smooth assembly of household appliance casings. AI robots adjust quickly to changes like resin thickness variations. They maintain steady part sizes with tolerances as small as 0.01 mm. This accuracy marks Silkbridge’s work on over 100 automated injection machines from 180 to 1,200 tons.

Main advantages include:

- Elevated Quality and Consistency: Robots work with steady accuracy. They reduce flaws in big production runs.

- Resource Optimization: Automation cuts energy waste by making workflows smoother. It also shrinks carbon footprints.

- Supply Chain Resilience: Robotics strengthen systems against interruptions. They support just-in-time production.

New developments like collaborative robots (cobots) make automation easier to use. Silkbridge applies robotic arms for insert molding and later steps like trimming and packaging. These run on fully automated lines.

As robotics improve, they help manufacturers deal with worker shortages directly. They build flexible production spaces that keep consumer applications ready for the market.

3. Prolonged Resin Shortage: Navigating Material Constraints Innovatively

The continuing resin shortage, made worse by unstable global supply chains, keeps challenging the plastic injection molding field. It raises prices and slows down launches of consumer products. Unlike short past shortages, this long-lasting problem hits engineered resins needed for varied uses. These range from tough toy parts to bendable packaging.

Materials that face issues include nylon, acetal, polysulfone (PSU), polyphthalamide (PPA), polyphenylene sulfide (PPS), polyphenylene oxide (PPO), and syndiotactic polystyrene (SPS).

Ways to handle it focus on teamwork and planning ahead:

- Qualifying alternative resins through testing

- Using fillers to match performance specs

- Blending recycled with virgin materials

- Predictive analytics for forecasting shortages

Silkbridge tackles this by offering a wider range of resins. They include bio-based PLA for toy molding. This choice avoids shortages in petroleum synthetics. It also helps meet standards like ASTM F963.

Active changes keep operations running smoothly. They even turn limits into chances for new material ideas.

4. Advanced Global Supply Chain Strategies: Building Resilient Partnerships

To handle resin price swings and shipping delays, smart global supply chain plans have become essential for plastic injection molding manufacturers. They target consumer applications. These plans highlight:

- Diversified sourcing

- High supply-chain visibility

- Agile logistics

- Digital tools (e.g., blockchain traceability)

Silkbridge shows this well with its turnkey EMS model. It combines PCB assembly with injection molding for complete consumer product handling. By keeping strong vendor connections across Asia and Europe, the factory lowers risks. Clients get reliable lead times even during worldwide changes.

In the end, these plans let manufacturers offer standout consumer applications. They also build lasting, creative partnerships.

Conclusion: Embracing Trends for Future-Proof Consumer Manufacturing

The mix of eco-consciousness, robotics, resin issues, and stronger supply chains shows a growing plastic injection molding industry. It focuses on what consumers want. By using these trends, manufacturers make products that are sustainable, efficient, and tough. Skilled partners like Silkbridge turn these changes into real benefits.

FAQ

What are the main biodegradable resins used in plastic injection molding for consumer products?

TPS, PHA, PLA, PBS, and PCL.

How does industrial robotics improve injection molding efficiency?

Robotics enhance precision, reduce waste, and cut cycle times by up to 30%.

What strategies help manage prolonged resin shortages?

Qualifying alternatives, supplier diversification, and predictive planning.

Why is global supply chain diversification important?

It builds redundancy and supports faster, more stable delivery.

How does Silkbridge support sustainable molding practices?

By using recycled/bio-based resins, automated lines, and ISO-certified processes

Partner with Silkbridge: Unlock Turnkey Consumer Products Excellence Today

As a trusted manufacturer, supplier, and factory specializing in PCBA and plastic injection molding, Silkbridge invites OEMs and contract manufacturers to team up on turnkey projects. These projects make full use of these trends. Whether qualifying sustainable resins, automating production lines, or fortifying supply chains, Silkbridge delivers precision parts with tolerances to 0.01 mm across 100+ machines. Contact the team today via WhatsApp at +86 18122838771 or contact@silkbridgeltd.com to request a quote. Elevate consumer applications with proven expertise. Start improving your workflow—reach out now for a customized consultation.