What is an LED PCB Board?

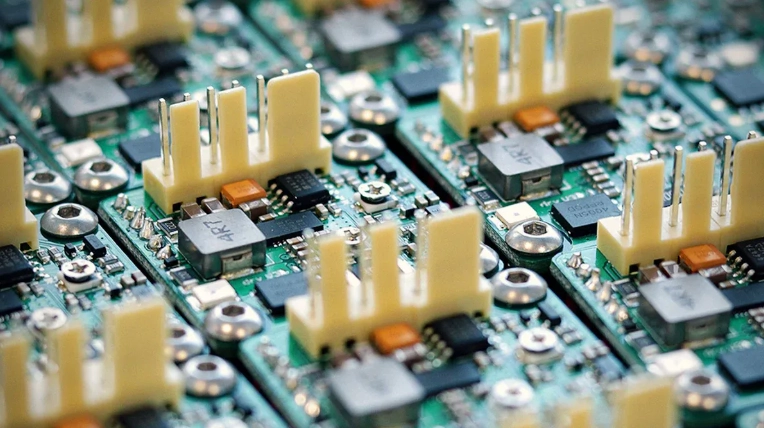

An LED PCB board is a printed circuit board designed to mount LEDs. Conductive traces in layers interconnected by PCB vias are engraved in the non-conductive materials. The pads exposed on the PCB component-mounting side are used for soldering. The electronic components on the LED PCB board are surface-mounted on the PCB pads, or through-hole soldered in the PTH holes.

On an LED printed circuit board assembly (PCBA), besides LEDs, there may be wiring harnesses and other components such as resistors and capacitors. These boards are crucial because LEDs are temperature-sensitive components, and the LED PCB is the medium to conduct heat quickly from the LED P-N joint to the external environment.

Types of LED PCB Boards

According to different performances in thermal dissipation, there are 6 types of LED PCB boards. The 6 types of LED PCB boards are aluminum LED PCB, copper-base LED PCB, FR4 LED PCB, ceramic LED PCB, hybrid substrate LED PCB, and flexible LED PCB.

Each type serves specific applications depending on its thermal conductivity, material composition, and structural flexibility. Selecting the right type ensures optimal performance and longevity of your lighting product.

Aluminum LED PCB

Aluminum PCBs are the most common and cost-effective printed circuit boards for LED lights, such as LED plant grow lights. Aluminum PCB design is relatively simple, and there are single-layer aluminum PCBs, two-layer single mounting-sided aluminum PCBs, two-layer dual mounting-sided aluminum PCBs, and four-layer dual mounting-sided aluminum PCBs.

In theory, aluminum PCBs provide a thermal conductivity range from 1W/mK to 9W/mK. Most usually, aluminum PCBs’ thermal conductivity is 1W/mK to 2W/mK. This makes them suitable for general-purpose lighting where moderate heat dissipation suffices.

For cost-effective and reliable aluminum LED boards, you can work with the aluminum PCB manufacturer Silkbridge.

Copper-base LED PCB

Copper-based PCBs are used for high-power LED lights, such as car headlights. Regular copper-base PCBs have the same structure as aluminum PCBs, but thermal conductivity is several times higher than that of aluminum PCBs.

There’s thermoelectric separation(or direct touch) technology for copper-base LED PCBs. The LED pad directly connects with the copper substrate and solders with LEDs. The heat generated from the LED P-N joint quickly dissipates to the copper substrate and then the external environment. In this way, thermoelectric separation copper-core LED PCB has thermal conductivity close to 398W/mK.

This makes copper-core options ideal for demanding applications requiring rapid heat transfer.

FR4 LED PCB

If the LED light is used as home daily lights and doesn’t require much thermal dissipation of the circuit board, an FR4 PCB can be a cost-effective circuit board option.

If you add metal frames to the FR4 LED PCB board, and the frames connect to the external environment, the FR4 PCB can also be used for high-power LED lights. However, fabrication can be more costly.

PCBONLINE provides FR4 PCB fabrication and assembly. The FR4 Tg of the laminates ranges from 135℃ to 220℃.

FR4 boards offer affordability but require careful design considerations if used in higher power settings.

Ceramic LED PCB

High-power LED lights, especially photography lights and swimming pool lights, use ceramic PCBs. Ceramic PCBs include aluminum nitride (AlN) PCBs, aluminum oxide (alumina) PCBs, boron oxide (BeO) PCBs, and silicon nitride (Si₃N₄) PCBs. The most common ceramic LED PCB boards are AlN PCBs and alumina PCBs.

AlN PCBs have 180W/mK thermal conductivity, and alumina PCBs have 20W/mK thermal conductivity. At high temperatures, BeO PCBs have much better thermal conductivity

However,BeO powders are toxic, making their production hazardous.

It should be noted that you should take care of the size of ceramic PCBs. Large-size ceramic PCBs can break when laminating during fabrication.

These boards offer excellent heat resistance but require precise handling during manufacturing.

Hybrid Substrate LED PCB

For high-power LED PCB boards, the substrate material can be hybrid. For example a ceramic PCB inlay in a copper board.

Hybrid substrate materials are connected by phase change they combine into a whole.

This allows engineers to customize both electrical routing and heat management pathways.

From hybrid substrate groups can be FR4/copper, FR4/polyimide etc., offering great flexibility for custom applications under long-term continuous operation conditions.

Flexible LED PCB

For flexible LED strips flexible PCBs with polyimide or polyester substrate are used. These are ideal for wearable devices or decorative lighting.

Flexible LED lights are much lighter than rigid ones they can blend and fold into any shape you want.

They support creative lighting designs where space or shape constraints exist.

You can even have transparent flexible PCBs made and assembled byPCB manufacturer , offering complete customization options.

Silkbridge One-Stop LED PCB Board Fabrication and Assembly Supplier

At Silkbridge we specialize in providing end-to-end services including product development, plastic injection molding, electronics manufacturing (including SMT), final assembly lines with strict QC processes—all under one roof in China since 2014.

Our R&D team comprises over 20 engineers from Western Europe and China who collaborate closely with clients throughout every stage—from concept through prototyping to mass production—ensuring optimal design performance.

Silkbridge operates fully automated SMT lines equipped with AOI (Automated Optical Inspection) and X-ray inspection systems ensuring that every assembled led pcb board meets exacting performance standards before shipment worldwide—including DDP shipping options covering customs duties/taxes at destination ports across USA/EU/Japan markets.

By integrating Western innovation with Chinese manufacturing efficiency,Silkbridge delivers reliable solutions whether you’re creating RGB/RGBW modules or complex multi-layer hybrid led pcb boards. We ensure seamless project execution—from initial idea through global distribution—making us your trusted partner in advanced electronics manufacturing.

For more information on developing and producing a new part or product, please contact Silkbridge on our business WhatsApp account https://wa.me/8618122838771 or call us on +86 8618122838771.