In fields like healthcare, pharmaceuticals, and biotechnology, keeping things spotless stays a total must. One tiny bit of dust might ruin a vital medicine or harm a medical implant. This shows clearly why clean room injection molding now plays a key role in making items for these areas. As accurate engineering improves, manufacturers like Silkbridge keep leading with modern setups that provide germ-free production spaces.

What is Clean Room Injection Molding?

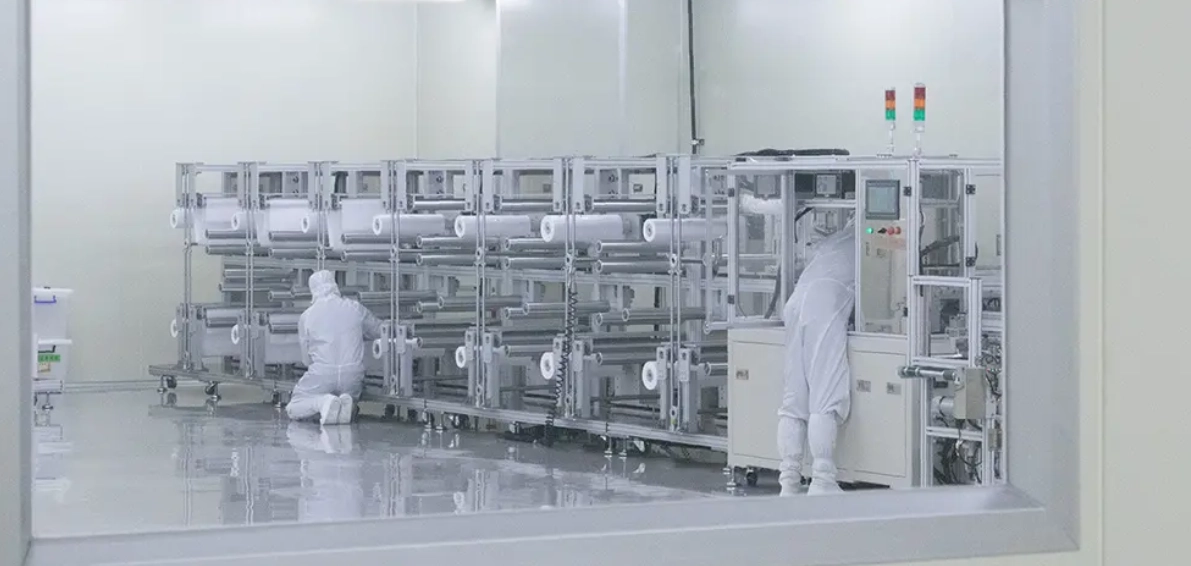

Clean rooms stand for tightly managed spaces built to lower the chance of floating particles entering products or tools. These areas successfully stop dust, grime, and germs from polluting delicate items during making steps. In injection molding, a clean room acts as a germ-free zone where plastic resins get melted, pushed into molds, and cooled down. The main goal stays to make sure final items reach tough safety and performance rules, especially in watched sectors.

This method turns vital in many fields where item purity directly affects human well-being or tech dependability. Silkbridge, a top manufacturer of plastic injection molded parts, shows this with its special controlled spaces for medical-grade components. The company’s setups follow strict cleanliness rules. They ensure accuracy and meeting standards from mold-making to final putting together.

Medical Industry

Clean room injection molding lets medical makers supply guaranteed-quality items to hospitals, clinics, and patients with trust. This way keeps medical devices safe. It thus boosts overall patient care results. Manufacturers create a wide range of germ-free parts. These include surgical tools, implants, drug delivery systems, and diagnostic gear.

Pharmaceutical Industry

The pharmaceutical field needs cleanliness and hygiene at a tiny level. Clean rooms help make items that match strict quality control rules and legal needs. Samples of things produced in these spotless settings include drug holders, medical devices, diagnostic tools, and special packaging stuff.

Silkbridge’s skill reaches pharmaceutical uses. Its ISO-certified quality control steps ensure production without pollutants. The manufacturer’s modern tools, including more than 30 CNC machines and 25 EDM units, allow building molds that fit pharmaceutical limits.

Biotechnology Industry

Experts in biotechnology know the urgent need for germ-free conditions when dealing with delicate living materials like cells, tissues, and tiny organisms. Clean rooms keep a pollutant-free space. This allows successful growth of high-germ-free devices like bioreactors, microfluidic devices, tissue engineering scaffolds, and gene therapy delivery systems.

Silkbridge aids biotechnology advances by giving full solutions that combine plastic injection molding with electronic assembly and product design.

Classifications of Clean Room

Clean rooms get grouped by their cleanliness grades. These depend on the allowed number and size of particles per cubic meter of air. Two main standards guide these groups. They offer measures for manufacturers around the world.

ISO 14644-1 (Formerly known as FS 209E)

ISO 14644-1 serves as the present global standard for clean room grouping. It replaced the older FS 209E. It sorts clean rooms from ISO 1—the purest, with fewest particles—to ISO 9, with higher particle allowances step by step. ISO 8, for instance, often aids medical device making by capping particles at 3,520,000 per cubic meter for sizes ≥0.5 μm.

While FS 209E, an old U.S. federal rule, grouped rooms from Class 1 to Class 100,000 based on particles per cubic foot, it has mostly been dropped for ISO measures. Fields like semiconductors sometimes mention FS 209E. But ISO 14644-1 leads for its worldwide use.

ISO 13485

ISO 13485 acts as a worldwide quality management system rule made for medical device making. Though it does not group clean rooms directly, it requires protections for quality and safety in germ-free spaces.

Main parts include:

Risk handling to reduce pollution dangers through the product life.

Design rules for picking clean-friendly materials.

Strict making steps covering clean room work, cleaning, staff training, and checking.

Clean Room Injection Molding Requirements

To follow ISO standards, clean room injection molding sites apply tough needs that manage setting factors. These steps build the base for stopping pollution.

Filtration System

High-Efficiency Particulate Air (HEPA) filters make the key part of clean room filtering. They catch 99.97% of particles ≥0.3 μm. Clean room groups often rely on HEPA work. This sets allowed particles per cubic meter.

For better filtering, Ultra Low Penetration Air (ULPA) filters grab even smaller particles. They improve germ-free levels in high-danger uses.

Airflow

Special air movement systems control air flow to keep cleanliness. Positive pressure airflow keeps inside pressure higher than outside. It pushes air out when doors open to stop pollutants from entering. On the other hand, negative pressure airflow pulls air in. It keeps dangerous stuff inside the room.

Airflow types also split into laminar—straight, even flow with little disturbance—and turbulent—mixed patterns for basic thinning.

Other Requirements

Besides filtering and airflow, sites control temperature to stop moisture buildup and germ growth. They usually keep it steady at 20-22°C. Humidity levels, often 40-60%, reduce static that might pull particles. Pressure differences between areas further separate pollution risks.

Clean Room Injection Molding Operating Procedure

Clean room injection molding uses a careful work process to create safe, useful items. Each stage adds quality checks to keep germ-free conditions.

Material preparation

Raw plastic resins go through picking and readying by quality rules. This includes drying or pre-heating for best flow. Medical-grade materials like those from Silkbridge ensure body-friendly traits from the start.Manufacturing

Resins melt and get pushed into accurate molds inside the clean room. Settings like temperature, pressure, and speed get set for even results. Silkbridge’s robotic machines shine here. They use EDM and CNC accuracy for complex shapes.Assembly

Several parts get put together with glues or holders in the germ-free area. This cuts handling dangers. Silkbridge’s combined assembly lines make this smooth for electronic-medical mixes.Packaging

Items get wrapped in guarding, low-particle materials to protect from after-making pollution during shipping.Testing

Eye checks, size confirmations, and function tests prove meeting rules. Silkbridge’s ISO steps include advanced non-harm testing.Product sterilization

Final germ-killing via ethylene oxide or gamma rays removes leftover germs. Silkbridge often uses these for pharmaceutical prep.

How to Select a Clean Room Injection Molding Manufacturer?

Picking a suitable clean room injection molding manufacturer depends on matching project needs. Main check points include:

Certification status under ISO 14644-1 for clean rooms or ISO 13485 for medical devices.

Clean room class fit, such as ISO 7 or 8, for certain uses.

Shown skill in the target field, backed by examples.

Access to pro injection molding tools meeting quality marks.

Engineering team’s skill in managing detailed designs.

Use of strong quality control steps.

Clear info on final-use areas, like medical or pharmaceutical.

Silkbridge stands out as a prime pick. It holds ISO 9001 and 13485 certifications, special ISO 8-level clean zones, and years of skill in medical-grade molding.

FAQ

What distinguishes clean room injection molding from standard injection molding?

Clean room injection molding happens in a managed, germ-free space to remove floating pollutants. Standard molding misses such tight particle controls. This makes it unfit for medical or pharmaceutical uses.

Which industries most commonly require clean room injection molding?

The medical, pharmaceutical, and biotechnology fields depend much on this process. It ensures item germ-free state and meeting legal rules.

What clean room classification is typically used for medical device production?

ISO 8 clean rooms get used often for medical device making. They allow up to 3,520,000 particles (≥0.5 μm) per cubic meter while keeping high germ-free levels.

How do HEPA filters contribute to clean room efficacy?

HEPA filters take out 99.97% of particles ≥0.3 μm from entering air. They form the base for ISO groups and stop pollution during molding.

What role does ISO 13485 play in clean room operations?

ISO 13485 sets quality management systems for medical devices. It stresses risk reduction, design rules, and process checks in clean room settings.

Can Silkbridge handle full turnkey production in clean rooms?

Yes, Silkbridge gives complete services from mold design and injection molding to assembly, testing, sterilization, and shipping in its managed spaces.

Partner with a Trusted Clean Room Injection Molding Manufacturer and Supplier

Medical device OEMs, pharmaceutical suppliers, and biotechnology firms look for dependable partners. These help simplify making while keeping top germ-free rules. As a leading plastic injection molding manufacturer and supplier, Silkbridge offers full solutions fitted for business needs. With ISO-certified clean room sites, modern robotic tools, and skill in medical-grade materials, Silkbridge guarantees accuracy, meeting rules, and growth for worldwide factory work.

Boost making speed and item quality by working with Silkbridge. This factory handles tough clean room tasks.

Reach the Silkbridge sales team now for a tailored quote. Learn how full services can speed up market entry.

📩 Email: contact@silkbridgeltd.com

🌐 Visit: www.silkbridgeltd.com to start your project talk.