Plastic injection molding among the common fabrication methods manufactures all kinds of parts and products for the most diverse industries. Proper material selection strongly supports the success of an injection molding project. With over 20,000 thermoforming resins commercially available, the task of choosing the ideal material can be overwhelming. Despite this, the ideal material will fall into place from the understanding of some key factors that can be listed as material properties, part requirements, and environmental considerations.

Understanding the Basics of Plastic Injection Molding

Materials cannot be selected for the plastic injection molding process without briefly understanding the fundamental process of plastic injection molding, along with its constituent type of materials that could be involved in the process.

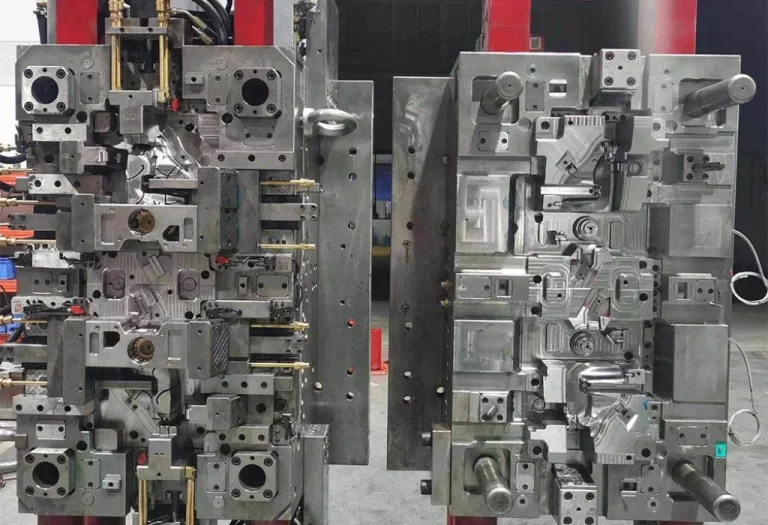

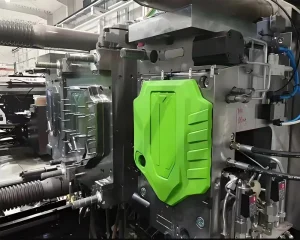

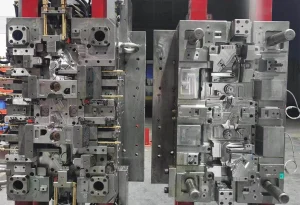

Plastic Injection Molding Process: Briefly, plastic injection molding refers to the process of manufacturing whereby melt plastic is introduced into a mold cavity, cools, and solidifies to form a desired part. The processes are generally characterized by precision, fast cycling times, and the production of superior quality.

Thermoplastics:Thermoplastics are the most utilized class of injection molded materials. The thermoplastic melts upon being subjected to high temperature, solidifying at lower temperatures, the process being reversible. Therefore, it can be melted, remolded and remelted repeatedly.

Thermosets: While going through the mold, the chemical change of thermoset takes place and can only be done once. This implies that it can never be melted again.

Considerations for Material Selection of Plastic Injection Molding

The best material for the injection molding process would be connected with several factors, all performance, functionality, and manufacturing of the part. Some key considerations include:

1. Mechanical Properties of Plastic Injection Molding Material

Mechanical properties define how the material shall act if it is subjected to stress or load. Important factors of the mechanical properties include:

- Tensile Strength:This measures the resistance of the material against being pulled apart, crucial in load-carrying parts.

- Flexural Modulus :The material resistance against bending is known as flexural modulus, which especially becomes vital when parts have to hold their shapes under loading.

- Impact Strength:Measures how much energy can be absorbed by the material before breaking. It shows how resistant to shock and/or dropping the parts can be

2. Thermal Properties of Plastic Injection Molding Material

Material will encounter temperature in various cases during molding, and afterwards the following :

HDT-Heat Deflection Temperature: This is the temperature under which material with certain loads starts to deflect. Applications under high temperature need high HDT.

Melting Temperature: This is the temperature range where materials change state from solid to liquid, and it needs to be suitable for injection molding to allow material flow.

Coefficient of Thermal Expansion: A smaller coefficient ensures less dimensional change, particularly for those parts which might be exposed to changes in temperature.

3. Chemical Resistance of Plastic Injection Molding Material

Chemical resistance is necessary for parts exposed to chemicals, solvents, or other corrosive elements. Consider:

Chemical Compatibility: Use a material that will not degrade due to the action of the specific chemicals the part will be exposed to.

Solvent Resistance: Materials that can be exposed to solvents may swell or even crack. Use solvent-resistant materials where appropriate.

Environmental Stress Cracking: There are materials which might fail due to the synergistic action of the stress and the chemical attack, hence materials must be selected which can offer resistance against such failures

4. Electrical Properties of Plastic Injection Molding Material

For electrical applications, the electrical properties of the material remain the most decisive:

Dielectric Strength: Gives the material’s resistance to electrical breakdown. The higher the dielectric strength, the better the material for insulation.

Volume Resistivity: Gives the resistance to flow of electrical current, and is an important property for insulated parts.

Surface Resistivity: This is needed to prevent electrical leakage, especially in high voltage applications.

5. Optical Properties of Plastic Injection Molding Material

Sometimes, transparency or some optical property is needed. To that effect:

Transparency: For those parts where clear visibility or light transmission is required, materials with high light transmittance are needed.

Color and Gloss: Materials can easily be color-matched through masterbatching, and surface finishes can be manipulated to arrive at specific levels of gloss-from matte to high-gloss.

6. Regulatory Compliance of Plastic Injection Molding Material

Materials in certain industries must comply with specific regulatory standards, which include:

FDA Compliance: It should be an FDA-compliant material for food contact and/or medical applications.

NSF Certification: It is the necessities for the material used in application related to the treatment of water or serving of food.

REACH and RoHS: They are European regulations; hence restrict the hazardous substances in materials; hence make a material choice that your device is within it whenever relevant.

7. Cost Considerations of Plastic Injection Molding Material

Costing of material determines the entire cost of the venture. Among key things one takes into account encompass:

Material Price: Commodity plastics such as PP and PE are less expensive than engineering plastics such as PC and PA. ·

Processing Costs: Certain materials may need higher processing temperatures or longer cycle times, raising the cost of production.

8. Sustainability and Recyclability of Plastic Injection Molding Material

With increasing consciousness about environmental responsibility, sustainability and recyclability be important:

Biodegradable Plastics: PLA and PHA are two of the popular options available to replace conventional plastics because they naturally degrade at the end of their life cycle.

Recycled Plastics: Recyclable materials could reduce the environmental burden caused by plastic production to a minimum. Most thermoplastics are recyclable and most recyclates can be used in injection molding.

Common Materials and Their Applications

Knowledge of properties and applications of common materials makes the selection process easier:

Acrylonitrile Butadiene Styrene (ABS): Known for toughness, impact resistance, and chemical resistance. Common in automotive components, consumer goods, and electronic housings.

Polyamide (PA, Nylon): Offers high strength and temperature tolerance. Used in gears, bearings, automotive parts, and medical devices.

Polycarbonate (PC): Strong, heat-resistant, and impact-resistant. Ideal for lenses, electrical components, and bulletproof glass.

Polyethylene (PE): Tough and inexpensive, used in packaging, containers, and plastic bags.

Polypropylene (PP): Flexible and resistant to acids, used in living hinges, medical tubing, and storage containers.

Polystyrene (PS): Optically clear and inexpensive. Often used in disposable containers, optics, and medical devices.

Thermoplastic Elastomers (TPE): Combine thermoplastic and rubber properties. Used in soft-touch buttons, overmoldings, and footwear.

Thermoplastic Polyurethane (TPU): Offers good temperature and chemical resistance. Common in medical devices, electronic casings, and footwear.

Acetal (POM): Strong and stiff, used in gears, pumps, and automotive switches.

Acrylic (PMMA): Known for optical clarity and scratch resistance, used in light pipes, lenses, and signs.

How to Optimize Plastic Injection Molding Material Selection

Seek Expert Advice: Specialists in injection molding will be able to advise on material selection with respect to your application. They will be able to guide through the maze of material properties coupled with process considerations.

Extensive testing: Do extensive testing of the chosen material under conditions as close as possible to the operation. It shall ensure that it would support mechanical, thermal, chemical, and electrical stresses expected.

Design For Manufacturing -DFM considerations: DFM considers designing the parts optimized for injection molding processes 37. It will provide effective reduction of manufacturing cost and improvement of part quality by reducing lead time.

Material Choices at Silkbridge for Injection Molding

Guangdong Province-based Silkbridge Electronic Technology is a company undertaking high-quality plastic injection molding for the electronics and medical devices industries, among others. Silkbridge Electronic Technology is all about integrating British innovation with efficient manufacturing in China to develop premium quality electronic product manufacturing solutions, with their products being distributed through major retail channels such as Walmart, Costco, and Amazon.

The Silkbridge facility is fully capable of full production, from concept design to the final assembly and packaging of products.

Materials span from:

- Thermoplasticssuch as ABS, PC, PP, PE, PS, TPE, TPU, and others, ensuring versatility in production.

- Eco-friendly materialslike PLA, PHA, and recycled plastics, offering sustainable options for clients.

Silkbridge’s facility is ISO 9001 certified, using superior quality steel in mold making; surface finishes are also available in various kinds. Its quality control and environmental protection furthermore ensure the products of higher quality will be greener.

Material Selection for Plastic Injection Molding Conclusion

Material selection for plastic injection molding is one of the most important and crucial decisions with respect to the success of your project. You can make informed decisions by considering properties inclusive of mechanical, thermal, chemical, electrical, and optical, considering regulatory requirements besides looking at aspects related to sustainability. This should best be addressed by collaboration with experienced professionals where thorough testing enables optimal material selection toward the best results on your injection molding project. To learn more about the plastic injection molding services available from Silkbridge, reach out to their team at contact@silkbridgeltd.com. Or our whatsapp link https://wa.me/8618122838771