When creating custom plastic enclosures for electronics, consumer goods, or industrial machinery, the chosen production method greatly shapes design choices. Injection molding shines as a top method for making these enclosures because of its ability to scale up, deliver accuracy, and manage complex shapes. This approach, though, requires close focus on many design factors to guarantee both good looks and solid performance.

Custom injection molded enclosures serve many fields, from housings for consumer electronics to protective casings for electric vehicle charging stations and tough shells for emergency medical devices. Skills in this area, gained from deep work in the custom injection molding field, stress the need to blend smart planning with real production facts.

Considerations for New Custom Plastic Enclosure Design

The User Experience

A product’s success in the market depends on smooth user contact with the enclosure, including how it links with inside parts, assembly items, and outside features. Engineers need to check mating surfaces, interference fits, and clearance spaces to avoid function problems.

For enclosures that need upkeep access, spotting entry spots for inside service matters a lot. This review sets tolerance rules and points out possible weak spots. In situations with doubt about assembly actions or fit tolerances, prototyping becomes a key check tool. Real prototypes let teams try actual interactions, and this cuts risks before full tooling starts. Such repeated testing makes sure the enclosure guards internals well and boosts overall ease of use.

Design for Manufacturing (DFM)

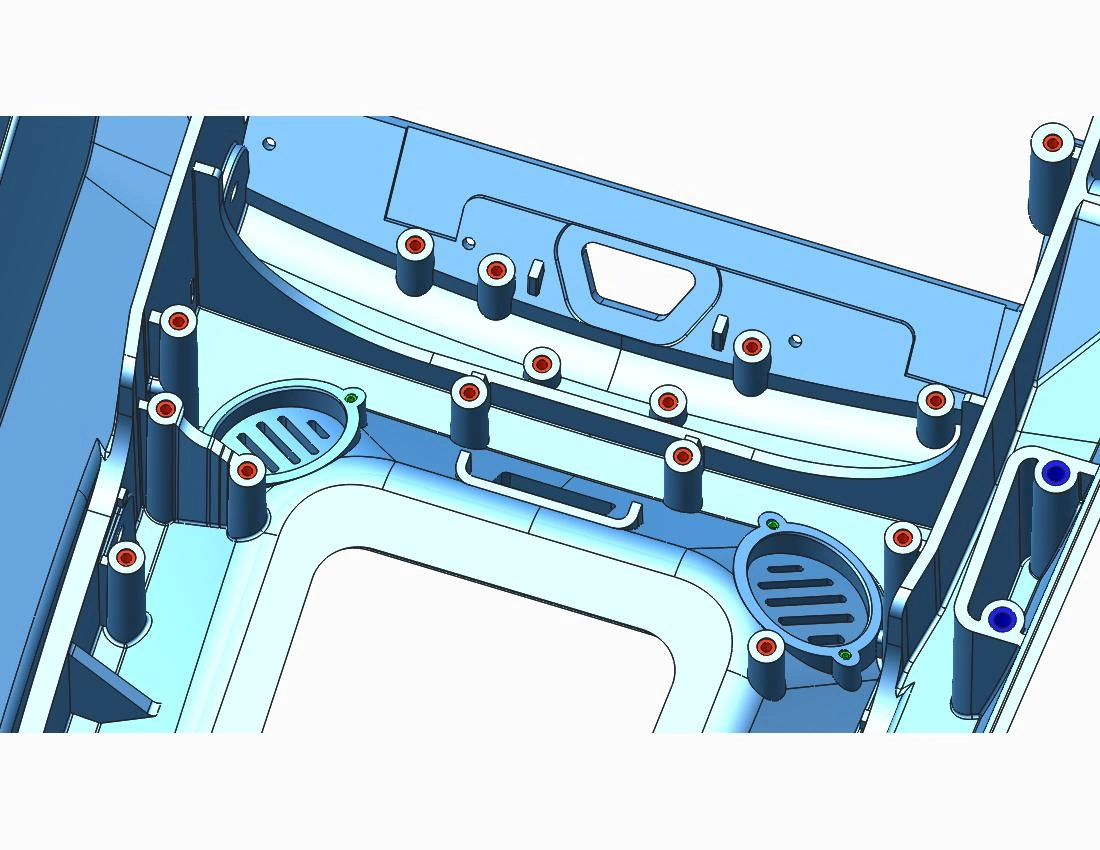

Tooling experts use early designs to build molds that boost output quality and speed. Important mold traits, such as gate spots and surface finishes, straight affect production results. Good DFM steps cut flaws, shortenYCLE times, and drop costs, so they are vital for enclosure jobs.

Gate Placement: Where It All Begins

The gate acts as the path for melted resin into the mold space, and it affects flow paths, material use, and surface looks. Smart gate spots curb waste, lower defect chances like flow lines, and keep visual quality on seen enclosure sides. Bad placement can cause uneven filling, and this harms structure evenness.

Wall Thickness: The Key to Structural Integrity

Even wall thickness builds the base for strong injection molded enclosures. Uniform parts help balanced cooling, and this stops twists like warping or sink marks that hurt size steadiness. Best thicknesses, usually from 2 to 4 millimeters for most enclosures, mix weight, strength, and material savings while aiding even resin spread.

Strength in Ribs and Reinforcements

To add stiffness without extra material, ribs and gussets give focused support. These parts fight bending, heat twisting, and load-caused warping in high-stress areas like mounting spots or load-carrying walls. Proper rib plans—thinner than the main wall and sloped for draft—avoid sink marks and ensure easy mold release.

Smooth Corners and Fillets for Durability

While sharp angles may boost style edge, they gather stresses, and this leads to crack growth under machine or heat loads. Adding fillets and radii spreads these forces, and it raises fatigue strength and eases resin flow in molding. A lowest radius of 0.5 times the wall thickness often works for best lasting power.

Navigating Undercuts and Complex Features

Undercuts—jutting parts that block straight-pull removal—need advanced mold tools like slides or lifters, and this raises complexity and cost. Designers handle this by moving features or using mold-friendly options, such as soft tapers, to simplify removal while keeping function.

Surface Finish and Texture: Practical and Aesthetic Impacts

Mold texturing stamps right onto enclosure outsides, and it changes touch feel, light bounce, and removal ease. Matte finishes improve grip for hand-held items, while glossy surfaces fit high-end looks. Textures also hide small flaws, but too rough patterns can hinder resin release, and this calls for release aids or mold coatings.

Material Selection: A Delicate Equation

Resin pick deeply sways enclosure success, covering machine traits, environment toughness, and process fit. Points like flame hold-back, chemical stand, and body-friendliness direct choices, along with shrink actions that set size buffers—often 0.5% to 2% based on the polymer. For example, enclosures meant for MRI nearness in medical spots skip metal inserts fully, and they favor non-iron resins like polycarbonate or ABS. Electromagnetic interference (EMI) and radio-frequency interference (RFI) shielding bring extra layers of challenge; conductive layers or built-in shield mixes ensure meet with rules like FCC Part 15. Supply chain checks further fine-tune picks, and they balance stock, cost, and power to match project schedules.

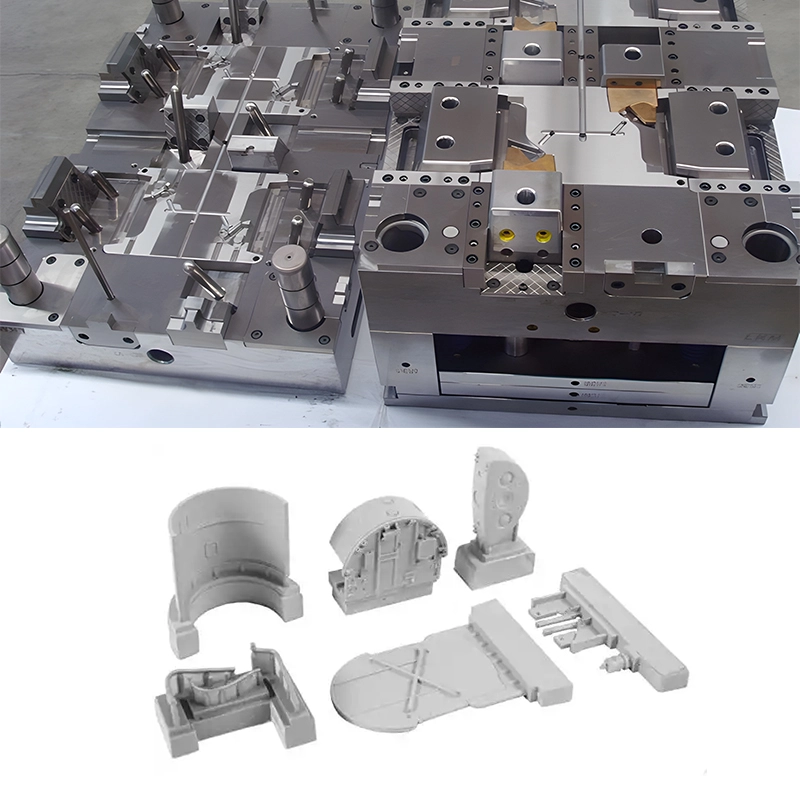

Striking the Balance of Mold Complexity

Fancy molds open new shapes but raise tooling spends and stretch lead times. Balance calls for checking feature need against production savings—simplifying less-key shapes without losing use. Advanced models predict workability, and this stops pricey fixes.

Integration of Assemblies: Beyond the Mold

Enclosure value goes to after-mold joining, where snap-fits, bosses, and alignment ribs aid quick linking. These parts must handle heat growth differences between materials, and this ensures steady seals and alignments in multi-part sets.

Tolerances: The Fine Print of Design

Injection molding’s exactness handles tight tolerances, yet changes like resin shrink, mold wear, and moisture need cushions. Standard tolerances (±0.1 mm for key features) guard working together, and stats process checks confirm steadiness across runs.

The Role of Moldability Analysis

CAD-based moldability checks spot issues early like knit lines or air traps, and this allows pre-tooling tweaks. Tools like Moldflow study fill paths, cooling actions, and warpage, and they cut repeat cycles and speed market entry.

FDA Requirements for Medical Devices

Medical enclosures require follow of FDA rules, and this sways resin body-friendliness (ISO 10993) and design proofs. Flame hold (UL 94), impact (ASTM D256), and UV/chemical stand testing put patient safety first, and they guide molders to approved materials and trackable steps.

Summary

Making plastic enclosures through injection molding weaves style polish, function strength, and build ease into one unit. The listed points—covering user-focused design, DFM needs, and material details—act as guides for creating enclosures that shine in power and production. Team engineering makes sure these parts join well, and it yields lasting, rule-meet products that fit end-user hopes.

FAQ

What is the ideal wall thickness for injection molded plastic enclosures?

Uniform wall thicknesses between 2-4 mm are recommended to ensure even cooling, minimize defects like sink marks, and maintain structural integrity without excessive material use.

How does gate placement affect enclosure quality?

Gate placement influences resin flow, potentially causing visible flow lines or uneven filling if poorly positioned. Optimal placement reduces defects and enhances surface aesthetics on exposed areas.

Why are ribs important in enclosure design?

Ribs add strength to thin walls, preventing flexing or warping under load, while optimizing material distribution for lightweight yet durable enclosures.

What materials are best for EMI/RFI shielding in enclosures?

Conductive polymers, carbon-filled compounds, or post-mold spray coatings like nickel-graphite provide effective shielding, ensuring compliance with standards for electronic and medical applications.

How can undercuts be managed in mold design?

By using slides or lifters in the mold or redesigning features with tapers, undercuts can be accommodated without complicating ejection, balancing complexity with cost.

Partner with a Trusted Injection Molding Manufacturer and Supplier for Your Custom Enclosure Needs

OEMs and engineering firms seeking reliable production of custom plastic enclosures benefit from partnering with an established injection molding manufacturer and supplier. As a premier factory specializing in high-precision molding, Silkbridge delivers turnkey solutions from mold design to assembly, leveraging over 100 advanced machines to produce 30 million parts annually. With expertise in medical, electronics, and consumer sectors, Silkbridge ensures ISO-certified quality and efficient scaling. Contact the Silkbridge team today at +86 18122838771 or via

Email contact@silkbridgeltd.com for a tailored quote and elevate your enclosure projects with British-inspired innovation and Chinese manufacturing prowess.