What Is Thin Wall?

Defining Thin Wall

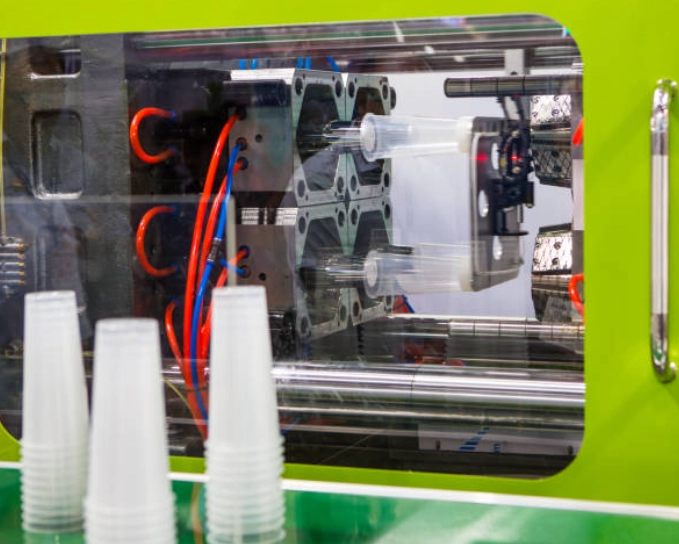

In the injection molding world, parts with walls thinner than 1mm are called thin-walled parts. This process is known as thin-wall injection molding. But thin wall isn’t just about thickness. It also involves the flow length to wall thickness ratio, plastic stickiness, and heat movement.

A key measure is the flow length ratio (L/t). Here, L is the flow length, and t is the wall thickness. If L/t is over 150, it’s thin wall injection molding. This high ratio brings special challenges for mold design, material choice, and process settings.

Why Use Thin Wall Injection Molding?

Thin wall injection molding saves money and works well. Plastic often makes up 50–80% of a product’s cost. Thinner walls use less plastic. This cuts costs and helps the environment.

Also, devices like cell phones, digital cameras, and PDAs are getting smaller and lighter. Their plastic parts need to be thinner. This makes thin-wall molding important for electronics, medical tools, car parts, and food packaging.

How Thin-Wall Filling Works

Filling the mold with melted plastic is a big part of thin-wall injection molding. The mold walls are cold. When melted plastic enters, a hard layer forms quickly. This makes the flow path narrower.

For example:

- A 1mm wall has a 0.2mm hard layer, leaving a 0.6mm flow path.

- A 0.5mm wall has a 0.2mm hard layer, leaving a 0.1mm flow path.

If the flow path closes before filling is done, problems like short shots or incomplete parts happen. Fast filling is key. Thin-wall molding needs high injection speed to fill the mold before the hard layer gets too thick.

Other Features of Thin Wall Injection Molding

Fast Injection and Low Inertia

Regular injection molding machines have a speed of about 100mm/s. This is too slow for thin walls. Special machines have medium (300–600 mm/s) to super fast (1000–2000 mm/s) speeds.

Speed isn’t enough, though. Starting and stopping fast matters too. If the injection takes only 0.5 seconds, the acceleration is over 8 G. Machines need low inertia parts to start and stop quickly while staying accurate.

Strong Systems and Control

To handle fast processes, the oil circuit needs to be strong. A rigid hose can replace a flexible one. Also, servo valves respond faster than regular valves. They control injection speed, holding pressure, and back pressure well.

Fully closed-loop systems check pressure and speed in real time. This makes adjustments during each cycle. In short, these systems make molding stable and cut down on bad parts.

Mold Design Considerations

Molds must be tough for high pressure. Use steel with hardness above HRC55 and heat-treat it. Exhaust slots are important. Enough slots or breathable mold steel reduce air resistance.

Gate design is key too. A big gate or multiple gates help prevent cooling closure. These steps ensure good part quality at fast speeds.

Material Selection

Choosing the right material matters a lot in thin-wall molding. Polyolefin materials like PP and PE are common. Others like PET, PS, ABS, and PC are used too. These materials flow well to fill the mold fast before it hardens.

Why Choose Silkbridge for Thin-Wall Plastic Injection

Silkbridge is great at high-precision thin-wall plastic injection molding. They serve industries like electronics, medical, and packaging. With over 100 advanced machines from 180 to 1200 tons, plus robotic arms, they make light, strong, and affordable parts.

They achieve tight tolerances of 0.01mm and fast cycle times. They produce millions of parts yearly with little material waste.

Key features include:

- Storing raw materials at exact temperature and humidity.

- Special areas for medical-grade plastic molding.

- In-house design and engineering help for new products.

- ISO-certified processes for steady quality.

By picking Silkbridge, you get top-notch machines and high-quality products. From prototypes to mass production, their smooth process meets strict industry needs while keeping costs low.

FAQ

What qualifies as “thin wall”?

Parts with walls thinner than 1mm are usually called thin-walled in injection molding.

Why does thin-wall molding need fast machines?

Thin walls cool fast during filling. A fast machine fills the mold before the plastic hardens and blocks the flow.

What plastics work for thin-wall molding?

Polyolefins like PP and PE are used most. PET, PS, ABS, and PC work too, based on their flow or strength needs.

Can Silkbridge meet medical-grade standards?

Yes, Silkbridge has special areas for medical-grade plastic molding. They ensure cleanliness and meet standards.

How do I start with Silkbridge?

To learn about making new parts or products, contact Silkbridge on their business WhatsApp at https://wa.me/8618122838771 or call +86 8618122838771.