Differences Between Conventional and Flexible PCBs

All PCBs do the same main job. They hold electronic parts. But their build and design differ. Conventional boards are stiff. They don’t bend. Flexible PCBs are soft. They can bend or twist to fit inside tight spaces or special shapes.

Flexible PCBs have neat perks over rigid boards. Makers can design flexible circuits to handle bending many times without breaking. They’re great for small spaces or tricky shapes.

Flexibility

Flexible PCBs can fold, bend, or crease to fit the final product.

Durability

Rigid PCBs are thicker and stronger. But flexible PCBs soak up shakes and bumps better.

Stability

Heat, radiation, or chemicals can harm rigid PCBs. Flexible PCBs stand up to these tough conditions better.

Reduced Weight

Flexible PCBs are lighter. This makes the final product weigh less.

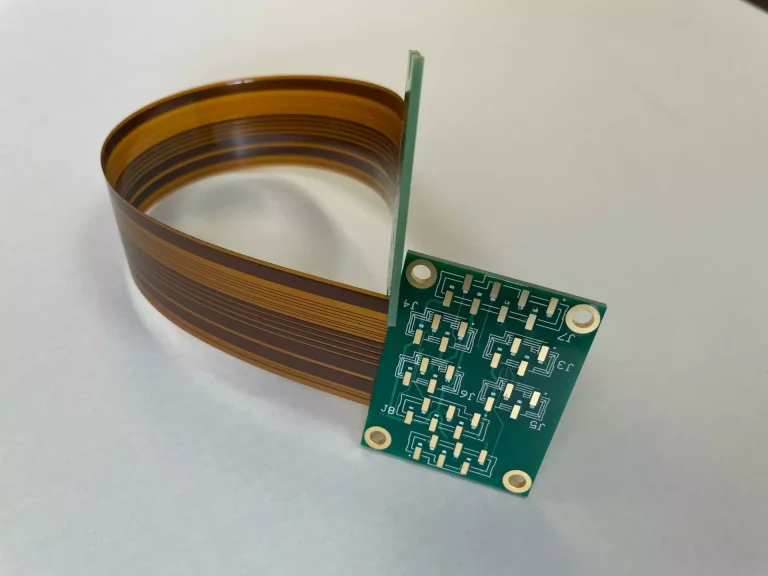

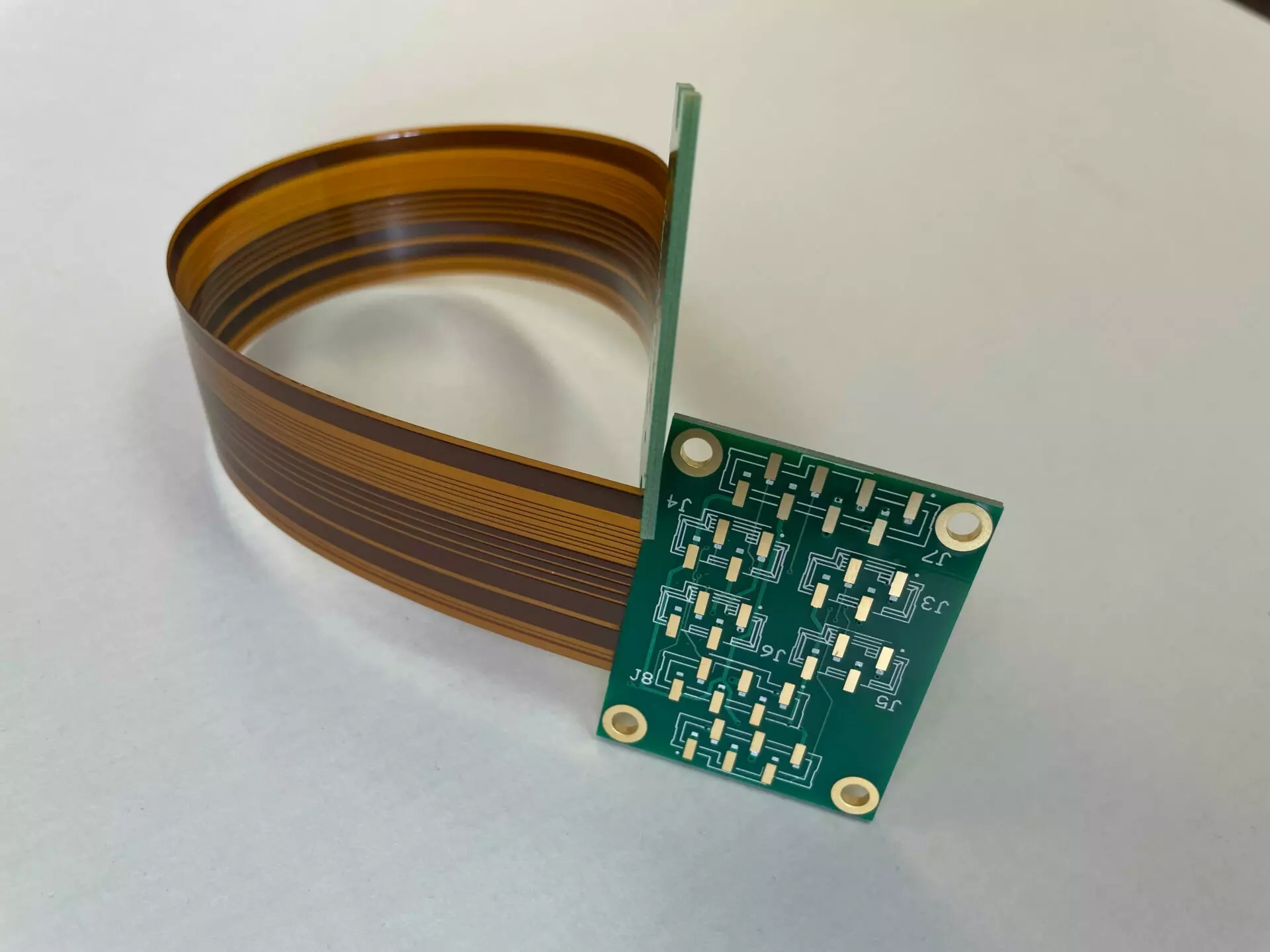

Rigid-Flex PCBs

Rigid-flex PCBs mix rigid and flexible parts. They combine the best of both while fixing some of their flaws. Makers layer flexible materials inside rigid board materials to create rigid-flex PCBs.

These boards simplify electronic designs. They cut out loose wire cables and connectors. This boosts electrical performance compared to regular PCBs. The biggest plus is that rigid-flex PCBs include all electrical and mechanical links as part of their build.

Construction of Flexible PCBs

Regular PCBs use a fiberglass or metal base. Flexible PCBs use a bendy polymer core, usually Polyimide film. Polyimide stays flexible after heating and doesn’t soften like other resins.

Makers prefer better Polyimide films over standard ones. These resist tearing and dampness well. Old designs used glue to bond parts, which wasn’t reliable. Now, makers use special Polyimide that sticks to copper without glue.

A coverlay film, also made of Polyimide, protects the copper surface. It works like a solder mask does for regular PCBs.

Construction of Rigid-Flex PCBs

In rigid-flex PCBs, stiff sections join bendy ones. Rigid parts use regular PCB materials, so they don’t bend. The board only flexes at the bendy sections.

Electrical signals move easily from rigid to flexible parts since it’s one single circuit. Supports make the rigid parts stay stiff.

For multi-layer rigid-flex PCBs, makers often use prepreg fiberglass for middle layers.

Popular Stackups

Single- and double-layer flexible boards have similar builds. They use a bendy polymer base and Polyimide film substrates. Flexible circuits might also have stiffeners made of FR-4 fiberglass or sticky adhesives (PSA).

Rigid-flex PCB builds can vary. A common setup uses four rigid layers and two flexible ones. It might include a core of adhesive-less Polyimide to avoid breaking risks.

Applications of Flexible and Rigid-Flex PCBs

Flexible and rigid-flex PCBs are key in many industries because they fit well in small designs.

Consumer Appliances

Electric irons, UV water purifiers, solar power systems, lighting, washing machines, TV remotes, microwaves, phones, media players, and wearable gadgets all use space-saving circuits.

Industrial/Manufacturing

They’re used in CCTV systems, control panels, industrial air conditioners, and automation setups.

Telecommunication

They go into routers, servers, signal expansion systems, and wireless base stations.

Aerospace

Important systems like motion sensors, GPS units, and avionics rely on trusty flex circuits.

Automotive

They’re in navigation systems, entertainment consoles, and control modules because they handle vibrations well.

Military

They’re used in tough tasks like tracking systems and missile guidance units.

Medical

They’re vital for small devices like pacemakers, cochlear implants, or handheld health tools where flexibility counts.

Silkbridge Flexible and Rigid-Flex PCBs Manufacturing and Assembly for Products

Silkbridge crafts high-quality rigid-flex PCBs for complex electronic setups. These mix the strength of rigid PCBs with the bendiness of flexible circuits. They spark new ideas for tight spaces like aerospace or wearables.

With top-notch manufacturing, Silkbridge delivers custom multi-layer designs that meet global standards. Options include:

- Multi-Layer Rigid-Flex PCBs: For high-density connections in advanced uses.

- Single-Sided Rigid-Flex PCBs: Budget-friendly for simpler systems.

- High-Frequency Rigid-Flex PCBs: For communication and RF systems.

For active settings like wearables or car dashboards needing foldable links without losing strength, Silkbridge’s flexible PCBs offer great toughness. These are perfect for:

- Wearable devices

- Medical tools

- Car displays

- Consumer gadgets like smartwatches or headphones

Whether for pcb prototypes or big production runs, Silkbridge provides solutions tailored to specific needs. Contact them via WhatsApp at +86 18122838771 for detailed technical help.

FAQ

What is a Rigid-Flex PCB?

A hybrid board with rigid areas for mounting parts and flexible areas for bending. It offers strength and layout freedom.

Why choose Rigid-Flex over traditional wiring?

Rigid-flex cuts out connectors and cables between parts. This improves electrical performance and reduces assembly mistakes compared to regular PCBs.

Can Flexible PCBs be used in high-frequency applications?

Yes. Silkbridge offers high-frequency flexible PCB designs made for RF communication gear.

Are these suitable for harsh environments?

Totally. Silkbridge’s designs meet global quality standards, ensuring toughness in tough conditions.