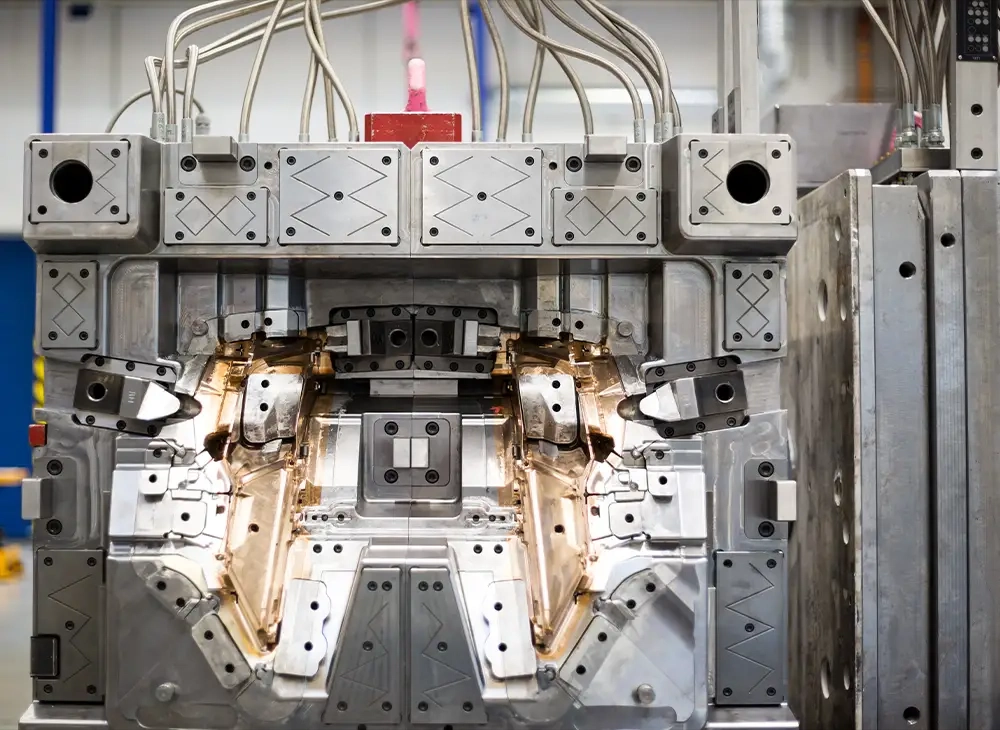

Plastic injection molding serves as a key base for today’s manufacturing. It allows quick creation of detailed parts that run everything from common household items to vital industrial gear. This method melts plastic resin and pushes it with strong force into carefully built molds. There, it cools and hardens into the end form.

The outcome is a flexible way to make tough, light, and cheap pieces in large numbers. At the core of this tech are Plastic injection mold manufacturers—skilled pros who plan, build, and keep up the molds that set product standards and production success.

Their job goes much further than simple making; they act as crucial links in turning idea sketches into big-scale factory truths. This piece looks into their help for new ideas and their effects on automotive, electronics, and medical fields.

Facilitating Innovation in Industries

Plastic injection mold manufacturers hold a central spot in the new ideas network. They change vague models into ready-for-scale production items. By using top-level computer programs and finite element analysis, these experts fine-tune mold plans to handle many rounds while fitting tricky shapes.

Such accuracy cuts down flaws like bending or dips. It makes sure parts hit strict limits often checked in microns.

Collaboration and Design Optimization

Teamwork builds the strong foundation of this work. Engineers bring in mold makers soon in the growth stage to polish plans for easy making (DFM). This back-and-forth method spots possible blocks—such as hidden cuts or slim sections—letting changes that better liquid movement and shorten round times.

Material Expertise and Sustainability

Choice of materials boosts their power even more. With deep know-how of thermoplastics like ABS, polycarbonate, and nylon, mold makers suggest mixes that match power, bend, and weather fight.

The use of nature-based polymers grows as fields chase green targets without hurting results.

Rapid Prototyping and Advanced Tooling

Quick model making stays a top sign of mold maker aid. Fast tooling ways—like 3D-printed pieces—allow speedy checks. They cut growth periods by months.

In tough settings such as aerospace or green energy, mold makers add better cooling paths. This raises output and success rates.

In the end, their skills lower waste, power use, and expenses. At the same time, they let fields stretch limits and stay quick during world supply changes.

Automotive Industry

The automotive field shows the must-have part of Plastic injection mold manufacturers. Light weight, exactness, and lasting strength matter for hitting fuel save rules and safety laws. Today’s cars include thousands of molded plastic pieces. This makes top-level tooling key.

Interior Components

Interior parts lead this use area.

· Dashboards need molds that copy soft-feel faces through overmolding methods.

· Door panels and consoles gain from gas-assist molding to cut material need while keeping power.

· Seat parts depend on molds built for high repeat to match crash-test rules.

Exterior Components

Exterior pieces bring extra hurdles.

· Bumpers from polypropylene mixes rely on slide-action cores for complex hidden cuts.

· Fenders and grilles often add pretty inserts via in-mold labeling.

· Headlight housings and floor rails use molds with conformal cooling for high shine and exact fit.

Engine and Under-the-Hood Parts

Engine parts highlight mold makers’ tech skill.

· Intake manifolds in glass-filled nylon need hot-runner systems to guarantee no-empty fills.

· Valve covers and oil pans require molds with vented plans to lower holes under hot conditions.

· These steps also aid electric vehicle growth. They allow battery cases with built-in cooling routes and light performance.

Electronics Industry

In electronics, small size and heat control guide advance. Mold makers provide tooling for tiny-level details and quick production rounds. They back the rise of smart gadgets and IoT tech.

Enclosures

Enclosures guard consumer electronics and demand high-exact molding.

· Phone cases often apply multi-material molding for tough build and germ-fight traits.

· Tablet and laptop enclosures join hinge parts via two-shot molding.

· Snap-fit groups trust pin placement to skip flash and ease putting together.

Connectors

Connectors stand as one of the top-exact groups.

· USB-C, HDMI, and power connectors rely on molds with swap inserts.

· Liquid crystal polymers fill super-fine spaces for steady electric work.

· High-cycle molds—lasting over a million shots—guarantee long-time trust.

Internal Components

Internal parts back heat and machine steady.

· Heat-leading plastics shape heatsinks with fine-tuned fin shapes.

· PCB housings depend on molds with align bosses for auto putting together.

· Fan shrouds apply helical-channeled molds to cut swirl and sound.

· Green molding, including recycled PET, rises too. Mold makers tweak gate plans to lower heat from cut. This lets use of after-use resins without result drop.

Medical Industry

Exactness and clean state set the medical field’s trust in mold makers. Molds must allow cleanroom-ready production and hit tough rules for safety and body match.

Medical Devices

Medical devices cover:

· Syringes, with plunger seals molded using zero-draft angles for smooth move.

· Catheters, needing multi-lumen molds with fragile core pins.

· Drug-delivery devices, using insert molding to wrap metal parts safely.

Surgical Instruments

Surgical tools need comfy and cleanable parts.

· Handles from glass-filled nylon reach grip feels via etched mold faces.

· Exact tips for forceps or clamps trust tiny parting lines for safety.

Diagnostic Equipment

Diagnostic gear includes:

· Ultrasound probe shells molded from shiny polycarbonate.

· Fluidic manifolds for analyzers, molded with valve seats to keep no-leak truth.

Compliance and Micro-Molding

Rule following pushes mold new ideas.

· Mold makers add date-code inserts for track during checks.

· Micro-molding backs microfluidic chips with paths under 100 microns.

· Green side grows through molds built for break-down polylactides in one-use parts.

FAQ

What is plastic injection molding?

Plastic injection molding is a manufacturing process that injects molten plastic into a mold cavity. It lets it cool and harden into an exact shape for high-volume production.

How do Plastic injection mold manufacturers support the automotive industry?

They plan and build molds for interior, exterior, and engine parts. They ensure light, tough pieces that boost efficiency and safety.

Why is material expertise important for mold makers in electronics?

It guarantees best pick of thermoplastics with the insulation, heat fight, and exact need for modern electronic devices.

What challenges do mold makers address in the medical sector?

They guarantee clean state, body match, and rule following to give no-dirt, high-exact parts.

How does early collaboration with mold makers accelerate innovation?

Early join allows plan fine-tune, quick model, and checks. It greatly cuts costs and time-to-market.

Why Choose Silkbridge as Your Plastic Injection Mold Manufacturer

As a leading manufacturer, supplier, and factory focusing on precision plastic injection molding, Silkbridge backs global firms with full production answers. Supported by British engineering skill and top Chinese making powers, Silkbridge gives:

· custom mold development

· PCBA and electronic assembly

· OEM/ODM project support

· integrated distribution solutions

· With more than 30 CNC machines, 25 EDM units, and advanced molding presses, Silkbridge guarantees steady quality, quick send, and grow-ready production.

Contact Silkbridge today to ask for a quote and team up with a trusted B-end manufacturing partner focused on raising industrial results.