Rapid prototyping is a powerful way to make new things. It helps people who design and build stuff create, try, and fix items fast. Picking the best way to prototype can decide if your project does well or not. This guide will show you the main parts of rapid prototyping, the types of rapid prototyping processes, important things to think about, and how Silkbridge Rapid Prototyping Service can help you win.

Understanding Rapid Prototyping

What is Rapid Prototyping?

Rapid prototyping is a way to make real copies of an item’s plan quickly. It’s an early step in making things that lets teams test ideas and make them better before making lots of them. By using the best rapid prototyping tools, like 3D printing or CNC machining, you can make a simple working model to get thoughts from others. Rapid prototyping and additive manufacturing, such as 3D printing, are liked because they are quick and can change easily. This way helps you see your item working and make fixes early.

Key Benefits of Rapid Prototyping

Rapid prototyping gives many good points. First, it saves time by making the planning step faster. You can try different versions of an item in days, not weeks. Next, it cuts costs by finding mistakes in the plan early, so you don’t need costly fixes later. Also, it makes teamwork better. Groups can share real models to talk about and improve ideas. Lastly, rapid prototyping design lets you change plans to fit special needs. These good points make rapid prototyping a must for making things today.

Types of Rapid Prototyping Processes

3D Printing for Rapid Prototyping

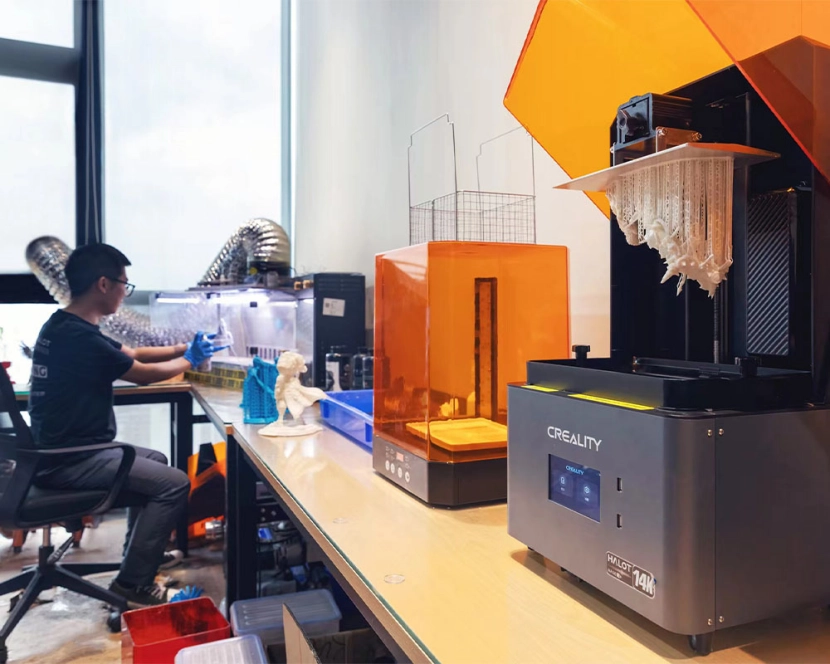

The 3D printing rapid prototyping process is one of the top ways today. It builds parts one layer at a time using things like plastics or sticky liquids. This way is great for making tricky shapes and checking product design and rapid prototyping. For example, 3D printing for the rapid prototyping of structural electronics lets builders make plastic parts with wires inside. At Silkbridge, modern 3D printing tools are used to make plastic parts fast. This ensures quick times for testing shape, fit, and use.

CNC Machining Rapid Prototyping

CNC machining rapid prototyping is perfect for making exact metal or plastic pieces. It uses computer-run tools to cut stuff from a solid chunk, giving high correctness. This way is awesome for rapid prototyping machining when you need tough, working parts. Silkbridge uses CNC machining for metal pieces, making sure they meet exact rules. This way is great for jobs like car or airplane making, where being exact is super important.

Rapid Prototyping Plastic Injection Molding

Rapid prototyping plastic injection molding is another big way, especially for plastic pieces. It means pouring melted plastic into a mold to make models. This way, also called rapid prototyping in plastic injection, is great for testing what are the plastic injection moulding prototypes before making tons of them. Silkbridge offers plastic injection prototype tooling and molding, using aluminum molds to keep costs low. Rapid injection molding prototypes are strong and have nice surfaces, making them a solid pick for everyday items.

Factors to Consider When Choosing a Prototyping Process

Material Requirements for Product Design and Rapid Prototyping

The stuff you pick changes the prototyping way. For example, if your item needs strong plastics, 3D printing or rapid prototyping plastic injection molding might be best. If you need metal pieces, CNC machining rapid prototyping is the right pick. Think about the stuff’s strength, stretchiness, and cost. Silkbridge helps people choose stuff that fits their product design and rapid prototyping goals. This makes sure the model works in real life.

Speed and Turnaround Time

Speed is super important in rapid prototyping. The 3D printing rapid prototyping process is often the fastest, making parts in hours. CNC machining takes a little longer but gives better exactness. Rapid prototyping in plastic injection might take more time because of mold making but is great for bigger groups. Look at your time plan and pick a way that balances speed and quality. Silkbridge’s know-how makes sure you get things fast without losing correctness.

Cost Considerations for Rapid Prototyping

Cost is a big deal. 3D printing is often the cheapest for small, fancy parts. CNC machining can cost more because of stuff prices. Rapid prototyping plastic injection molding needs mold costs at first but is cheaper for lots of models. To save money, skip extra coatings and use cheap stuff for early models. Silkbridge’s help, like electrical prototype injection mold wholesale, keeps costs low while giving great models.

Applications of Rapid Prototyping

Rapid Prototyping Electronics and Structural Components

Rapid prototyping electronics is key for testing wire boards and electric setups. For example, 3D printing for the rapid prototyping of structural electronics lets builders put wires into plastic pieces. Silkbridge’s electric experts make working wire boards during prototyping. This allows real-world testing. It makes sure your item’s electronics work well with other parts, cutting risks when making lots.

Rapid Prototyping in Consumer Product Development

Rapid prototyping is widely used in consumer products, from gadgets to household items. It allows designers to test product design and rapid prototyping for usability and aesthetics. For instance, rapid prototyping machining can create durable prototypes for testing fit and function. Silkbridge collaborates with clients to refine consumer product designs, ensuring they meet market demands before production.

Transitioning to Production with Rapid Injection Molding Prototypes

Going from prototyping to making lots can be hard. Rapid injection molding prototypes help make this easier by using the same way as making lots. This makes sure your model matches the final item’s quality. Silkbridge’s rapid prototyping in plastic injection services help people test and check plans. This makes moving to big making smooth and good.

Best Practices for Effective Rapid Prototyping

Refining Rapid Prototyping Design with CAD Software

A good model starts with a great plan. Refining rapid prototyping design with 3D CAD software is super important. Silkbridge uses modern CAD tools to make every part of your item perfect. This step makes sure the model matches what you want. It also finds problems early, saving time and money.

Testing and Validation in Rapid Prototyping

Testing is the heart of rapid prototyping. Check your model’s shape, fit, and use with real-world tests. For rapid prototyping electronics, test wires under tough conditions. For plastic pieces, check if they’re tough. Silkbridge’s prototyping way includes careful testing. This makes sure your item is ready for making.

Collaboration with Silkbridge Rapid Prototyping Service

Working together is key to good prototyping. Silkbridge Rapid Prototyping Service mixes British new ideas with Chinese making skills. Started in 2014, Silkbridge gives full help, from item planning to prototyping. Their team works closely with people, giving smart advice and great models. Whether you need 3D printing, CNC machining, or rapid prototyping plastic injection molding, Silkbridge gets results.

Conclusion

Why Choose Silkbridge for Your Prototyping Needs?

Picking the right rapid prototyping process is super important for making your item real. By knowing the types of rapid prototyping and thinking about key things, you can make models that reach your goals. Following good ways also helps. Silkbridge Rapid Prototyping Service is your trusted helper in this trip. With skills in the best rapid prototyping tools and a promise to quality, Silkbridge helps you make your item perfect. Ready to start? Contact Silkbridge on their business WhatsApp at https://wa.me/8618122838771 or call +86 8618122838771, Email contact@silkbridgeltd.com to learn more about their new prototyping solutions.