What Is Injection Molding?

At its heart, injection molding is a way of making things by pouring hot, melted stuff into a special mold. This method, often used with plastics, helps create lots of parts with tricky shapes and fine details. What makes injection molding so handy is that it works with all sorts of stuff—like soft plastics, hard plastics, metals, and even glass. This flexibility lets makers craft detailed pieces with amazing accuracy, which is why it’s a key tool in many fields.

What are the Applications of Injection Molding in Various Industries?

The uses of injection molding are as wide-ranging as the fields that rely on it. This way of making things is used to build everything from tiny, exact pieces for medical tools to big, tough parts for building and car-making.

Construction Industry

In the building world, injection molding is super important for creating strong parts like connectors, brackets, and covers for equipment. Some main uses are: window and door frames that are both tough and nice to look at; plumbing bits like joints and valves; electrical boxes and protective covers; and pieces for modular building projects.

Food Industry

For food and drink companies, injection molding helps make safe packaging and products. Things like bottle caps, containers, and utensils are made with safe materials to meet health rules and keep everyone protected.

Medical Injection Molding

In the health field, injection molding is a big deal for making top-notch, long-lasting, and clean parts. These can be small things like test kits and x-ray pieces or bigger items like covers for MRI machines.

Defense Industry

In the defense world, injection molding is a must for crafting parts that need to be super strong and handle rough conditions. Key uses include airplane parts, protective gear like helmets, firearm pieces such as grips and stocks, and cases for communication tools.

Agriculture Implements and Tools

Injection molding has changed farming by offering tough, weather-proof parts needed for today’s agriculture. Products include machine bits for tractors and harvesters, pieces for watering systems, storage containers, and tools like shovels that are comfy to hold.

Electronic Industry

In the electronics field, the sharpness and flexibility of injection molding are vital for making parts for all kinds of gadgets. Common uses are covers for cell phones, computer bits like keyboard keys, systems to manage cables, and cases for sound gear like speakers or remotes.

Furniture Industry

The furniture world has fully welcomed injection molding for its awesome ability to create strong, good-looking, and fresh designs. Examples are chair bases shaped for comfort, table legs, outdoor furniture that stands up to bad weather, stackable shelf units, and office desk items like organizers or cable holders.

Musical Industry

The music world gains a lot from the exactness and steadiness of injection molding. Main uses include guitar picks, drumsticks, mouthpieces for wind instruments, keyboard keys, tuning pegs for string instruments, and hard cases to protect gear.

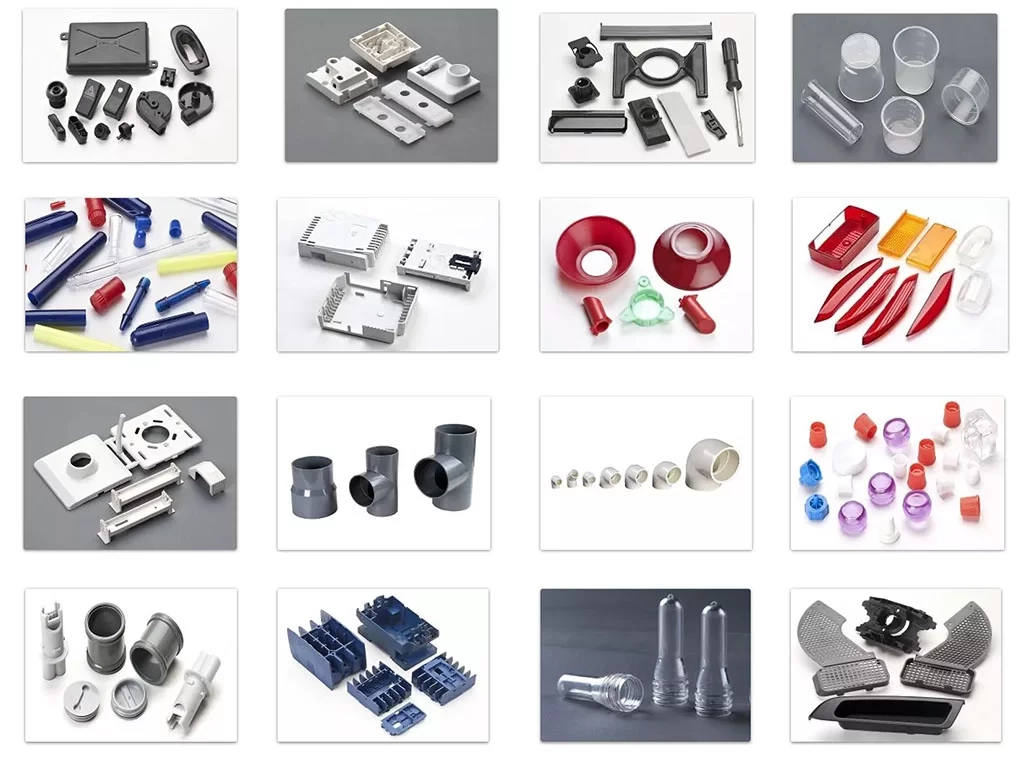

What Products Are Commonly Created Through Injection Molding?

Overview of product types

The wide range of injection molding shines through in the huge variety of things it helps make. This method is key in many areas, producing items we use every day. For consumer electronics, it’s not just phone cases but also high-quality plastic bits inside gadgets. In medical devices, it includes tools for surgery that keep patients safe and clean. For automotive parts, think dashboard pieces that show off the skill to make complex shapes with sturdy stuff. Everyday home items like kitchen tools highlight its role in our lives. And for packaging, beverage containers show the need for safe and useful solutions.

What Are Some Innovative Products Made with Injection Molding?

Injection molding has opened doors to new ideas, creating items that work well and also challenge the limits of design. Some cool examples are advanced fake limbs that move like real ones, light parts for space travel, and green materials used in earth-friendly products.

What Materials Are Used in Injection Molding?

Lots of different materials can be used in this process, depending on what’s needed for the job.

Thermoplastics

Thermoplastics are the top pick for injection molding because they’re so flexible and can be reused. They’re liked for being able to heat up and reshape over again. Some examples are:

- ABS: Used for toys or gadget covers.

- Polyethylene: Used for bottles or bags.

- Polycarbonate: Used for lenses or screens.

Thermosetting Polymers

Once these materials harden, they can’t be melted again. They’re picked when heat resistance matters. Examples include:

- Epoxy Resins: Found in electronics.

- Phenolic Resins: Used in cars and airplanes.

- Silicone: Seen in cookware or medical tools.

Elastomers

These are used for stuff that needs to bend. Examples are:

- Seals and gaskets

- Car hoses

- Belts

Metals

Metal injection molding helps make tricky metal parts with great detail. Examples include:

- Surgical tools

- Firearm mechanisms

Glass

Used in special cases where clearness is needed. Examples are:

- Optical lenses

- Pretty fixtures

Confections

In the food world, injection molding is used in fun ways for things like candy molds and chocolates shaped in neat designs.

FAQ

Q: What makes injection molding great for making lots of stuff?

A: It can repeat the same quality over thousands or even millions of pieces.

Q: Can eco-friendly plastics be used?

A: Yes—bioplastics work just like regular thermoplastics in this process.

Q: How is overmolding different?

A: Overmolding mixes different materials—like soft rubber over hard plastic—to make things better.

Q: Is metal injection molding worth the cost?

A: For small, detailed metal parts made in big numbers—yes—it can save money compared to other methods.

Choose Silkbridge – Precision Injection Molding for Your Products

If you’re looking for trusty partners for your next batch of products using top-notch injection molding—from the first idea to the final piece—Silkbridge is here for you. We’re experts in:

Plastic Enclosures, made just for electronic gadgets.

Medical-grade Injection Parts, meeting all health safety rules.

Automotive Parts, crafted with careful skill.

Consumer Goods, like kitchen tools or home items.

Overmolded Parts, mixing plastic with rubber for extra use.

By using the latest methods shaped to your needs across fields—from electronics to farming—we turn your ideas into real things with quick production and skilled know-how.

For more information on developing and producing a new part or product, please contact Silkbridge on our business WhatsApp account https://wa.me/8618122838771 or call us on +86 8618122838771.