What Are the LEGOs?

LEGOs are famous toys made of plastic bricks that lock together. They can build many things like houses, figures, or models. The name “LEGO” comes from the LEGO Group, a company started in Denmark in the 1930s. In the 1950s, their toys got super popular. Now, “LEGO” often means any toy with similar snap-together parts.

These toys are fun and teach skills. They help kids and adults think about space, get creative, and solve problems. Besides LEGO Group products, other companies make similar toys using injection molding. These parts fit together the same way.

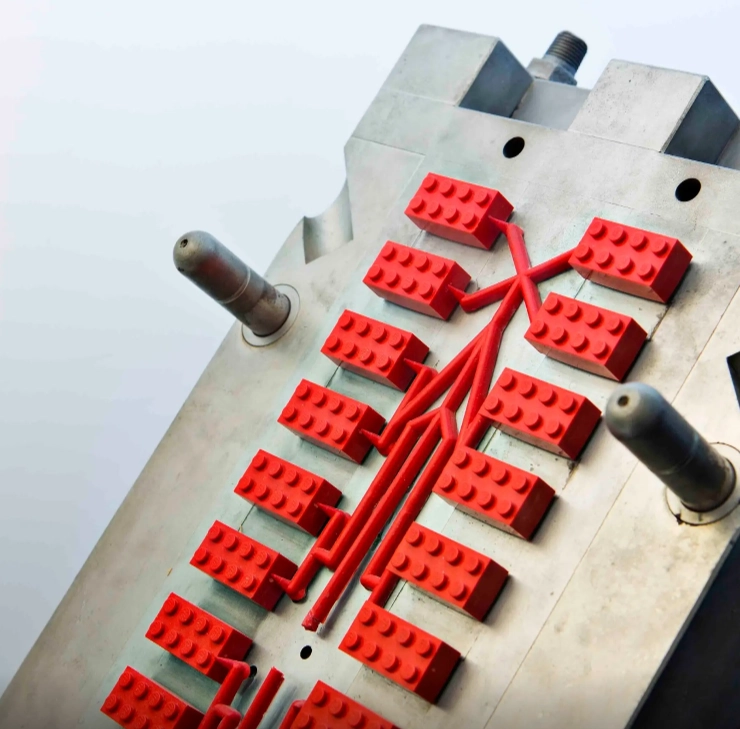

The Process of Lego Injection Molding

Injection molding LEGO follows steps like regular plastic molding. But it’s tweaked for the super exact parts LEGO needs.

Mold Design

It starts with a digital model. Tools like CAD or Solidworks make a virtual mold. This ensures the right size and fit for interlocking parts.

Mold Manufacturing

Molds are made with CNC machines, EDM, or sometimes laser cutting. CNC uses CAM codes to shape LEGO molds. Tight fits and fine details are key for accurate LEGOs.

Material Selection

The main material is Acrylonitrile Butadiene Styrene (ABS). ABS is strong, resists impacts, and lasts long. It also fights corrosion and wear.

Machine Setup & Injection

Molds go into an injection molding machine. Settings like heat (up to 450°C), pressure (around 150 tons), and timing are set. A nozzle shoots melted ABS through a runner. The liquid fills the mold’s tiny details.

Curing & Ejection

The mold cools fast, often in 10 seconds. This hardens the plastic. Then, pins or automatic systems pop the LEGO part out.

Post-Processing

Extra bits, called flashes, get trimmed off. Some parts get polished or painted for the final look.

Benefits of Using Plastic Injection Molding For Lego Toys

Injection molding brings big perks for making LEGO toys:

Precision and Tight Tolerances

It can hit super exact sizes, down to ±0.01mm. This makes pieces lock together perfectly.

High-Cost Efficiency

Steel molds last for up to a million cycles. This cuts costs for big batches. For small runs or testing, silicone molds are a cheaper option.

Color Versatility

ABS comes in tons of colors. This lets makers create bright sets without extra coloring steps.

Durability & Surface Finish

Injection molding makes smooth, tough LEGO parts. The high pressure gives a neat look and strong function.

What Can be Made with LEGO or LEGO-like Injection Molding?

Injection molding isn’t just for bricks. It makes all kinds of creative stuff:

- Quick test models of custom LEGO-like toys.

- Standard bricks and mini-figures.

- Keychains and small accessories.

- Duplo blocks for young kids.

- School kits for learning.

- Clear windows or windscreens for models.

- Special collectible items.

It creates toys, art, snap-together decor, games, and more.

Effective Five Tips for LEGO Injection Molding

To make top-quality LEGO parts:

Maintain Tight Tolerances

Keep sizes exact. This helps parts fit and work well when snapped together.

Use Mirror EDM & Wire Cut Techniques

Wire EDM cuts tiny details. Mirror EDM makes mold surfaces super smooth.

Implement Rigorous Quality Control Inspections

Use tools like CMM machines or micrometers. These check if parts are the right size.

Address Common Defects Early On

Watch for issues like sink marks, jetting, or burn marks. Fix designs before big runs.

Cooling Time Optimization

Cooling takes about 10 seconds for standard LEGO parts. Adjust for bigger parts or different materials.

Summing Up

LEGO injection molding mixes high precision with low costs. It makes strong toys with great finishes. Whether making regular bricks or custom figures, this method works well for small or big batches.

For businesses wanting pro-level LEGO-like products, a skilled manufacturer is key. Silkbridge offers full services, from mold design to final assembly, all in-house.

FAQs

Can I use injection molding for LEGOs?

Yes. Precision injection molding works for LEGO bricks. It’s great for both testing and big production.

How much does a LEGO injection mold cost?

A LEGO mold costs $20,000 to over $150,000. It depends on complexity and how long it needs to last.

What is the cooling period for injection molding LEGOs?

Cooling takes 5 to 10 seconds for most LEGO parts. Bigger ones may need more time.

Which material is used for LEGO injection molding?

Acrylonitrile Butadiene Styrene (ABS) is the top choice. It’s strong, light, and gives a great finish.

Get Your Injection Molding Lego from Silkbridge

Silkbridge makes over 30 million plastic parts yearly. They use machines from 180 to 1200 tons. Their facility has over 30 CNC machines for top accuracy.

Their all-in-one services cover R&D to distribution. This makes Silkbridge a great partner for turning LEGO-like ideas into real products fast.

For more information on developing and producing a new part or product, please contact Silkbridge on our business WhatsApp account https://wa.me/8618122838771 or call us on +86 8618122838771.