What’s Large Part Injection Molding?

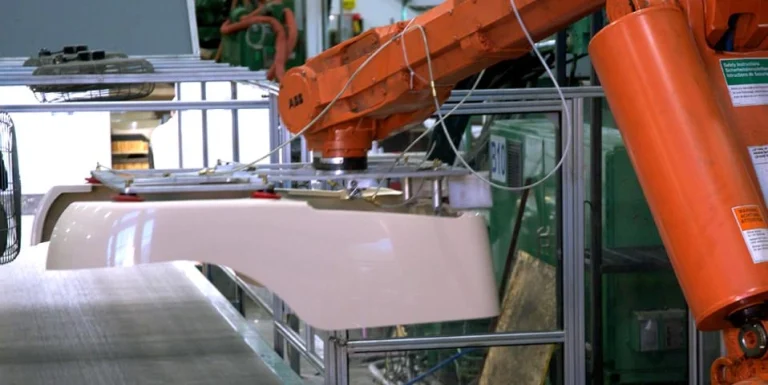

Large part injection molding is a cool way to make big, tricky plastic parts. It’s used for stuff like car body panels, construction gear, huge storage bins, and industrial things. This method is a total game-changer for creating tough, super precise parts in big batches.

Large part injection molding means making plastic pieces too big for regular machines. It needs bigger injection molding machines with stronger clamping forces and larger shot sizes to handle giant molds. The biggest machine out there has 8000 tons of force and can handle a shot weight of 325 pounds.

Usually, these big molds need a clamping force of 500 tons or more. The machines are built to deal with lots of molten plastic and the heavy stress of shaping large parts.

Picking the Right Injection Molding Machine for Big Parts

Choosing the right machine is super important for large part injection molding. First, know the part’s size and weight. Figure out how big, heavy, and complex the parts will be. Big parts need machines that can handle larger sizes and heavier loads.

Clamping force is a big deal too. For big parts, a lot of force is needed to push back against the pressure from the molten plastic. Large part injection molding often needs machines with clamping forces from 1,000 to 10,000 tons or more.

Shot size has to be big enough to fill large mold cavities. Shot size is the most plastic a machine can shoot in one go. It’s smart to pick a machine with at least 20% extra capacity for changes in design or material.

Also, the mold size must fit the machine’s platen dimensions for smooth work. Cool features like multi-zone heating, servo-driven controls, and gas-assisted injection make things more precise and save energy.

Large Part Injection Molding Process

Getting the Mold Ready

Before starting, clean the mold well. Remove dust, moisture, or bits that could mess up the injection. Adding a release agent stops molten plastic from sticking, making it easier to pop the part out later.

Clamping

The mold’s two halves are locked tight using a big-tonnage injection molding machine. This is key to handle the huge pressures during injection, which can go over 20,000 psi.

Injection

Plastic pellets go into a hopper. Then, they’re melted into liquid resin with heat and a spinning screw. The molten plastic gets shot into the mold cavity at high pressure.

Cooling

Cooling time changes based on part size, wall thickness, and material type. For big parts, cooling can take a while and needs extra care.

Ejection

The clamping unit lets go of pressure, so the mold can open. Ejector pins or other tools push the finished part out without breaking or bending it.

Checking and Finishing Up

After popping out, parts get checked to make sure they meet standards. Look for issues like warping or sink marks. Depending on the job, parts might need trimming or assembling next.

Challenges of Large Part Injection Molding

Material Flow and Fill Issues

Bigger parts mean the molten plastic has to travel farther. This can lead to uneven flow. That might cause gaps or incomplete parts. Using materials that flow better and tweaking gate or runner designs can help.

Cooling Time and Temperature Control

Cooling is a huge part of injection molding, especially for big parts. Long cooling times and uneven cooling can cause shrinking or warping. Conformal cooling channels keep things even.

Machine Size and Clamping Force Challenges

Big parts need injection molding machines with way more clamping force and shot size. Too little force can cause flash or unfilled molds. Real-time monitoring keeps pressure just right during production.

Keeping Parts Strong and Defect-Free

Big parts can get internal stresses that lead to cracks or bending during making or use. Surface flaws like sink marks can show up if material flow isn’t steady.

Managing Cycle Time

Big part cycle times are a lot longer than for small parts. This slows down production. Simulation tools help speed up cycles while keeping quality high.

Wall Thickness Challenges

If walls are too thin, flow gets tough. Thick walls mean longer cooling times. The wall needs to balance strength with being easy to make.

Why Choose Silkbridge for Large Injection Molded Parts

Silkbridge is awesome at making large injection molded plastic parts for industries needing tough, precise solutions. With machines up to 1200 tons, Silkbridge churns out huge parts like enclosures, panels, automotive parts, and industrial housings.

Their skills ensure super strong parts, spot-on sizes, and nice finishes for big parts. Clients get full support, from design to mass production, with eco-friendly practices. Silkbridge helps industries like automotive, construction, and electronics with custom solutions using engineering-grade plastics.

- WhatsApp: +86 18122838771

- Phone: +86 18122838771

- Email:contact@silkbridgeltd.com

FAQs About Large Parts Injection Molding

How Big Can You Injection Mold?

The biggest injection molding machine out there has 8000 tons and a shot weight capacity of 325 pounds. Machines like these make huge items, like car bumpers or industrial panels, super efficiently.

What Are Injection Molds Made Of?

Molds for big parts are usually made from hardened steel because it’s tough under high pressure. Aluminum can work for prototyping but wears out faster over many cycles.

How Does Part Design Affect Large Part Injection Molding?

Design stuff like even wall thickness affects how well the mold fills and cools. Tricky shapes might need special gating systems or gas-assisted tricks for the best results. Proper draft angles make ejection easy and reduce stress on parts.

For top-notch large part injection molding, Silkbridge delivers the goods. Check out their solutions for custom parts that rock any industry!