On-Demand Manufacturing in Injection Molding

The Concept of On-Demand Manufacturing

On-demand manufacturing is a game-changing method in the production world. Products are made only when needed. This avoids mass production and storage. It fits perfectly with Low-Volume Injection Molding. Businesses can quickly meet market needs. They avoid overproduction or extra stock. By using this approach, companies boost efficiency. They cut waste. They also meet custom needs accurately.

Key Benefits of Low-Volume Injection Molding

Cost-Effectiveness for Small Batch Production

Low-Volume Injection Molding is great for small batch production. It saves money. Unlike traditional high-volume methods, it needs less money for tools and setup. Low-volume molds are cheaper and faster to make than high-volume ones. This makes it perfect for startups, small companies, or projects needing small amounts.

Also, this method lowers financial risks. Companies avoid making large quantities that might not sell. They can test the market with small runs first. Then, they decide on larger production. This ensures smarter use of resources.

Faster Production Cycles and Lead Times

Quick Turnaround for Prototypes and Products

One major advantage of Low-Volume Injection Molding is speed. It offers fast production cycles and short lead times. The process uses low-volume steel molds. These are simple and quick to create. As a result, the time from design to final product shrinks.

For prototypes or new product launches, this speed is priceless. Companies can turn ideas into reality fast. They seize market opportunities or improve designs based on feedback.

Flexibility in Design Adjustments and Iterations

Accommodating Design Modifications with Ease

Low-Volume Injection Molding provides great flexibility for design changes. Mold making for low-volume production allows easy updates. These updates don’t cost too much. This is vital during prototyping or when customer needs change.

Designers can try different shapes, materials, or finishes. They don’t worry about big delays or costs. This flexible approach encourages creativity. It ensures the final product meets both practical and visual needs.

Design Considerations for Low-Volume Plastic Parts

Material Selection for Durability and Functionality

Commonly Used Plastics in Low-Volume Molding

Choosing the right material is key for low-volume plastic parts. The material must balance strength, function, and cost. Common plastics in Low-Volume Injection Molding include ABS, polypropylene, polycarbonate, and nylon. Each has unique traits for specific uses:

- ABS: Known for its strength and impact resistance.

- Polypropylene: Light but strong, great for consumer products.

- Polycarbonate: Offers clear visuals and toughness.

- Nylon: Famous for wear resistance and mechanical strength.

Material choice should match the part’s purpose. Consider factors like weather, load, and chemical exposure.

Optimizing Part Geometry for Efficient Molding

Avoiding Design Complexities to Reduce Costs

Smart part geometry is crucial for Low-Volume Injection Molding. Complex designs raise mold-making time and costs. They also make molding harder. Simple geometry streamlines production. It keeps functionality intact.

Low-volume mold designs focus on reducing complex features. These features could slow manufacturing. Features like even wall thickness, rounded corners, and simple undercuts improve moldability. They also reduce material waste.

Balancing Aesthetics and Performance in Designs

Looks matter in product design, along with function. Balancing beauty and performance ensures happy customers. It doesn’t sacrifice practicality. Surface finishes, like textures or gloss, can be tailored during molding. This achieves the desired look.

Also, adding features like snap fits or interlocking parts improves usability. These don’t need extra assembly steps. By focusing on both form and function, manufacturers create appealing products. They also keep costs low.

Low-Volume Injection Molding shows how advanced techniques meet modern needs. It supports flexibility, customization, and eco-friendly production.

The Process of Low Volume Plastic Molding

Steps Involved in Low-Volume Plastic Injection Molding

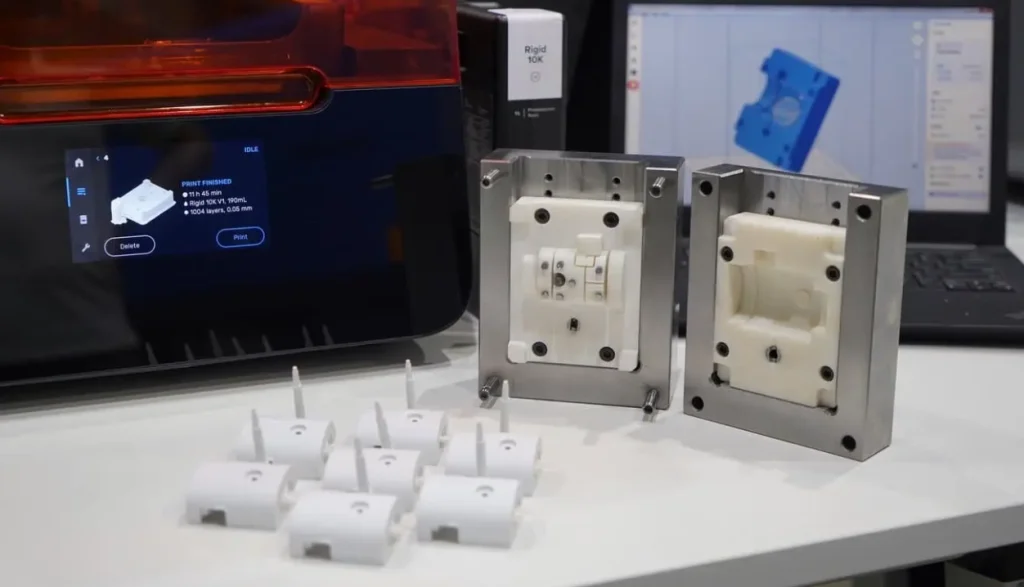

Mold Creation and Setup for Small Batches

Low-Volume Injection Molding starts with mold creation. These molds are designed for small batch production. They are affordable and quick to make compared to high-volume molds. Typically, they use materials like aluminum or low-volume steel. These are cost-effective and strong enough for limited runs.

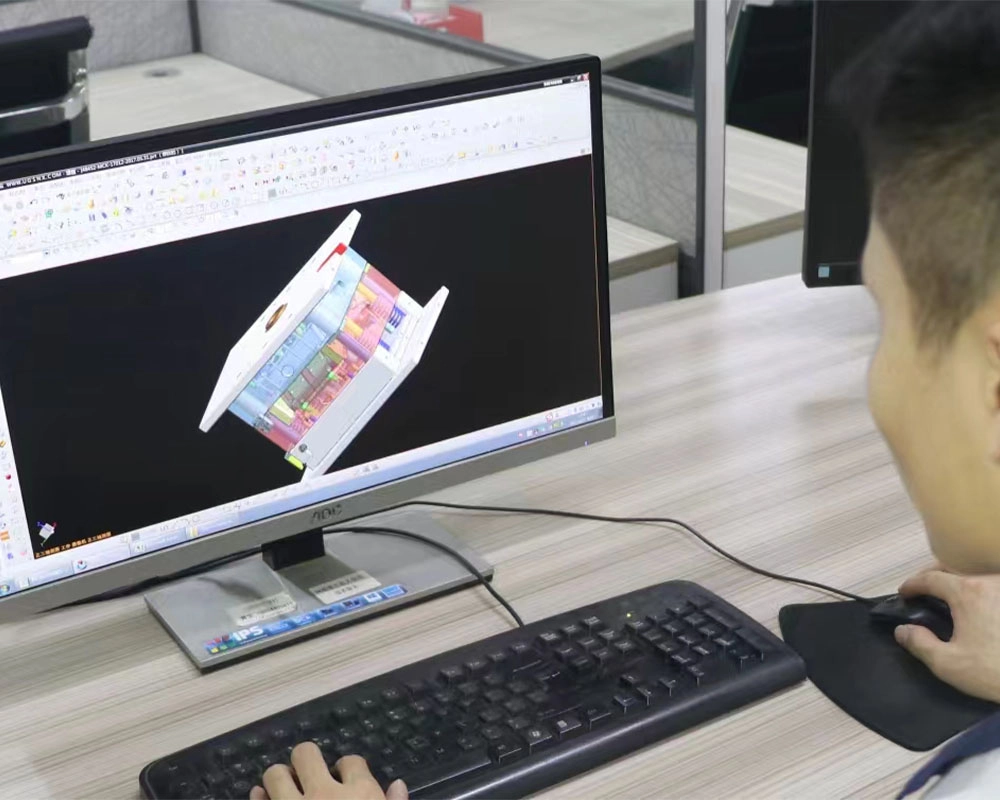

Mold making requires precise engineering. The mold must match the product design perfectly. Low-volume molds allow changes without high costs. This is helpful during prototyping or for small customer tweaks. Once the mold is ready, it’s set up in the injection molding machine. All settings, like temperature and pressure, are carefully adjusted.

Injection, Cooling, and Ejection Phases Explained

The molding process has three main steps: injection, cooling, and ejection. In the injection step, molten plastic is pushed into the mold under high pressure. The material fills every part of the mold. This ensures the design is copied exactly.

Next is the cooling step. The molten plastic hardens as it cools in the mold. Cooling time depends on material, wall thickness, and part complexity. Efficient cooling systems in the mold speed up this step. They also maintain part quality.

Finally, the ejection step removes the solid part from the mold. Ejector pins or plates are used. This step is done carefully to avoid damaging delicate features. The cycle then repeats for more parts.

Quality Assurance Measures in Small Batch Production

Quality assurance is vital in Low-Volume Injection Molding. Every part must meet high standards. Inspections include checking dimensions, looking for surface flaws, and testing function. Advanced tools like 3D scanning or coordinate measuring machines (CMM) verify accuracy against designs.

Also, low-volume production lets manufacturers spot and fix issues early. This avoids big costs or delays. This proactive method reduces waste. It boosts overall efficiency.

Key Applications of Low-Volume Injection Molding

Prototyping New Product Designs with Precision

Low-Volume Injection Molding is a key tool for prototyping. It lets designers create functional prototypes. These prototypes closely match final production parts in material and shape. The process uses low-volume steel molds. These are easier and faster to make. This helps businesses bring ideas to life quickly.

Prototypes offer valuable insights into performance, usability, and looks. They can be tested in real-world conditions. This allows improvements before full production.

Producing Replacement Parts or Custom Components

Low-Volume Injection Molding is also great for making replacement parts or custom components. Industries like automotive, aerospace, and healthcare often need unique parts. These parts may not be available from regular suppliers. They may also need customization.

Low-volume molds are designed for these tasks. They produce high-quality parts efficiently. This avoids long lead times or high costs. This is especially useful for maintaining old equipment or meeting niche needs.

Supporting Niche Markets with Specialized Products

Low-Volume Injection Molding shines in niche markets. These markets don’t need large production runs. Examples include medical devices for specific patients, consumer products with unique branding, or industrial parts for special machines.

This method’s flexibility lets businesses respond to market trends or customer needs. They don’t overcommit resources. It also supports innovation. Companies can test new ideas on a small scale before expanding.

Silkbridge Plastic Injection Molding

Silkbridge excels in Low-Volume Injection Molding projects. They handle every step, from design consultation to final delivery. Their work ensures smooth execution tailored to client needs.

By using advanced tools and materials for small batches, Silkbridge delivers top quality. They keep costs low. Whether you need prototypes for a new idea or custom parts for a niche, Silkbridge’s low-volume molds offer great precision and reliability.

Their focus on customer satisfaction goes beyond manufacturing. Silkbridge offers advice on material choice, design improvements, and efficient mold designs. This enhances project results.

Low-Volume Injection Molding is a flexible solution. It meets diverse industry needs effectively. It minimizes waste and maximizes value at every production step.

- WhatsApp: +86 18122838771

- Phone: +86 18122838771

- Email:contact@silkbridgeltd.com