Features of Color Masterbatch In Injection Molding

Masterbatch is a type of colorant used for polymer materials commonly employed in the plastics industry. It is a pigment preparation consisting of pigments or dyes, a carrier resin, and additives. This formulation enables efficient and uniform dispersion of color into plastic resins during injection molding.

During the production of the color masterbatch, the pigment undergoes refinement processes to enhance its dispersion and coloring power within the final product. The carrier resin is carefully selected to match the base polymer used in the product, ensuring compatibility and optimal dispersion.

Another key advantage lies in pigment protection. When pigments are incorporated into color masterbatch, they are protected within the carrier material. This helps maintain the chemical stability of the pigments by minimizing direct exposure to air and moisture, ensuring their quality and performance over time.

Additionally, color masterbatch particles have similar characteristics to resin particles, facilitating convenient and accurate measurement. The compatibility between the color masterbatch and the resin prevents sticking during mixing, promoting uniform dispersion throughout the plastic matrix.

How To Use the Color Masterbatch

The application process for injection color masterbatch is straightforward. The use of color masterbatch is very simple, just mix it with resin particles in the prescribed ratio and mix it. This makes it accessible even for manufacturers without specialized equipment.

Color masterbatch can be used with various resins such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), acrylonitrile butadiene styrene (ABS), among others. Each resin’s melt flow index and thermal behavior must be considered to ensure compatibility with the selected masterbatch.

Shelf Life of Color Masterbatch

One of the significant benefits of using injection color masterbatch is its long shelf life. The dispersal and fixation of pigments within the carrier resin in color masterbatch create a closed system, allowing for long-term storage without degradation.

However, proper storage conditions are essential. Storing color masterbatch in a dry and cool environment is highly recommended to prevent moisture absorption, potential oxidation, and other adverse effects that could impact the quality and performance of the pigments and carrier resin.

By adhering to proper storage practices, the quality and effectiveness of the color masterbatch can be preserved.

Defects and Solutions When Using the Color Masterbatch In Injection Molding

Despite its advantages, defects may occur when using injection color masterbatch. Some common issues include:

Non-melting and Color Dots Defect

The melt finger of the color masterbatch and the melt finger of the product raw material do not match, resulting in poor diffusion of the color masterbatch. To resolve this issue: Increase the melt flow properties of the masterbatch to enhance its fluidity.

Short molding time can also lead to incomplete plasticization: Select a suitable production process that allows sufficient time for complete plasticization.

High molecular weight particles may cause defects: Implement quality control measures. Utilize mesh filters to remove high molecular weight particles.

The Color Difference Between Sealed Sample And Product

Color inconsistency can stem from several causes:

- Inconsistent color quality control at the color masterbatch factory

- Variations in raw materialsdifferences in turbidity or whiteness

- Changes in inorganic fillers or molding parameters

- Electrostatic phenomena during mixing

- Process control parameter deviations

Solutions include using reputable suppliers, maintaining raw material consistency, fixing formulations, reducing static electricity during mixing, and implementing strict process controls.

Color Differences Occur When Using Different Equipment

Even with identical formulas, different machines can produce varying results. It is recommended to carefully examine process parameters and ensure they fall within a certain range. If discrepancies persist after adjustments: the problem may lie in the temperature resistance aspects of the colorants used.

Color Streaking Under Sunlight

Color streaking results from uneven pigment dispersion. Causes include:

- Inadequate mixing

- Pigment-resin incompatibility

- Improper processing conditions

- Melt flow inconsistencies

To mitigate streaking:

Optimize mixing, adjust processing parameters like temperature or screw speed, evaluate pigment-resin compatibility thoroughly, and implement stringent quality controls.

The Problem Of Color Masterbatch Leading To Increased Product Breakage

Breakage may result from:

- Incompatibility between base resin and masterbatch

- Excessive loading levels

- Poor dispersion

- Reduced melt flow properties

Solutions include:

Select a compatible color masterbatch, follow recommended loading ratios,use effective mixing techniques, optimize compounding parameters,and conduct thorough testing.

Non-melting and Color Dots Defect

This defect deserves special attention due to its visual impact on finished products. As stated earlier:

Increase melt flow properties, allow adequate plasticization time,and remove high molecular weight particles through filtration. These steps help achieve homogenous coloration without visible dots or unmelted fragments.

Does the Use of Color Masterbatch Increase the Cost of the Product?

This question concerns both manufacturers and end users. While it might seem more expensive initially,coloring with masterbatch can be more economical compared to coloring with powders.

Color masterbatch allows colorists to achieve desired coloring effects by combining lower-priced pigments.

Color masterbatch provides consistent color formulations…minimizing waste.

Products colored with masterbatch often command higher selling prices due to their enhanced aesthetics.

Thus, while unit costs may rise slightly,

the overall value proposition improves through savings on waste reduction and premium pricing opportunities.

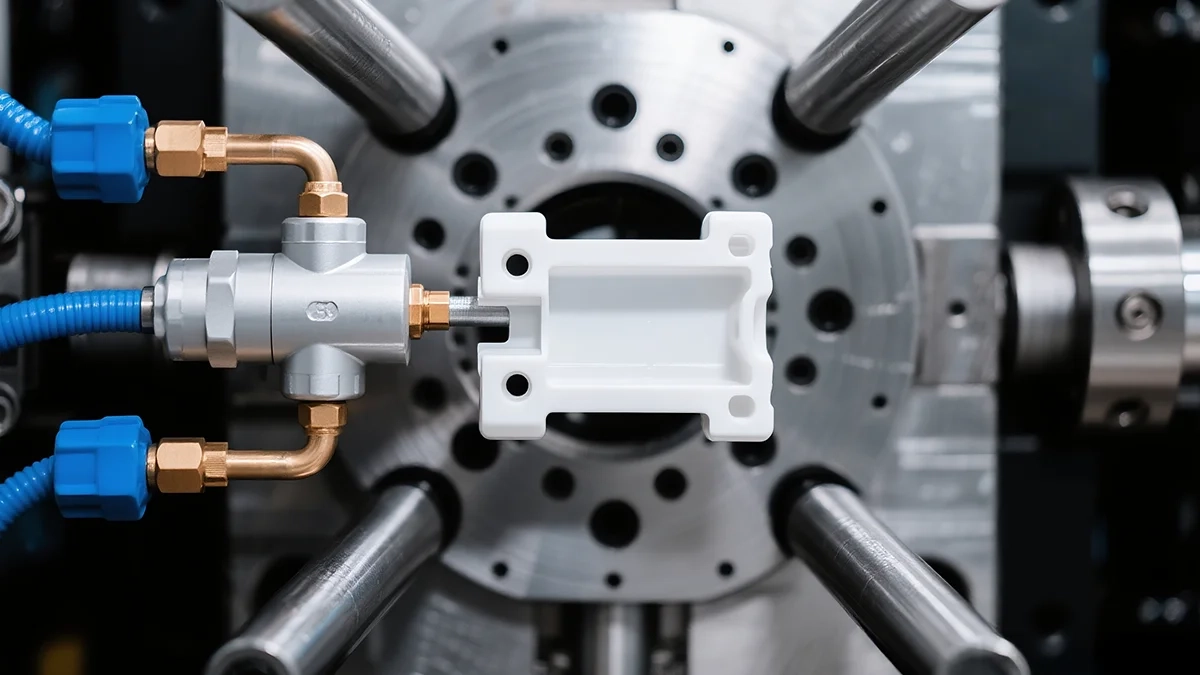

Silkbridge Injection Molding services for your products

Silkbridge offers professional injection molding services that integrate advanced use of injection color masterbatch solutions tailored for diverse applications.

At Silkbridge, we produce over 30 million plastic injection parts annually, utilizing 100 state-of-the-art injection molding machines ranging from 180 tons to 1200 tons. Our facilities are equipped with advanced technology capable of handling complex designs and tight tolerances across various industries including automotive, medical devices, consumer electronics, industrial components, packaging solutions—and more.

We provide end-to-end support including mold design optimization for better flow characteristics when using colored resins; precise dosing systems for accurate color matching; as well as post-processing inspections ensuring aesthetic consistency across all parts produced using injection color masterbatch solutions.

Whether you’re working with PE or ABS substrates or facing challenges like breakage due to improper formulation ratios—Silkbridge’s engineering support helps identify ideal formulations that balance cost-efficiency with visual appeal.

- WhatsApp: +86 18122838771

- Phone: +86 18122838771

- Email:contact@silkbridgeltd.com

FAQ

Q1: What resins are compatible with injection color masterbatch?

A1: Commonly used resins include PE, PP, PVC, PS, ABS among others.

Q2: Can I store unused masterbatch long-term?

A2: Yes.

The closed system created by dispersal within carrier resins allows long-term storage without degradation if stored properly.

Q3: How do I prevent streaks caused by poor dispersion?

A3: Ensure adequate mixing