Injection molding cycle time is a reflection of production efficiency. A comprehensive understanding of this cycle is crucial, as it not only dictates the quality of the final product but also impacts the overall production timeline. Reducing the plastic injection molding cycle time directly enhances throughput and lowers manufacturing costs, making it a critical focus for manufacturers striving for operational excellence.

Estimating the Injection Molding Cycle Time: Key Components and Calculations

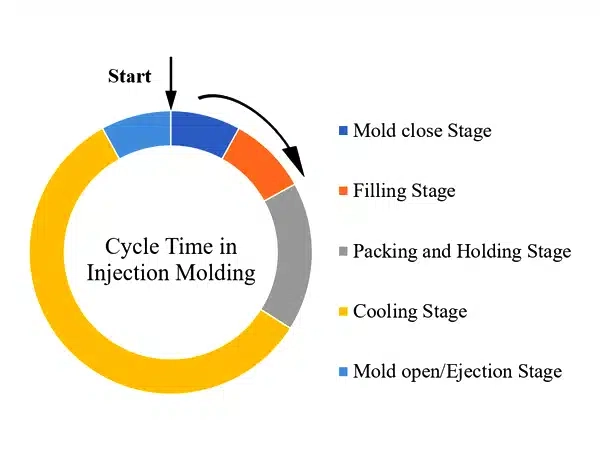

Injection molding is a cyclical process, and understanding its various stages is essential for optimizing production efficiency. The injection molding cycle time, often synonymous with terms like “injection molding process” or “plastic molding cycle,” comprises several crucial components:

Cycle Components

Material Storage Time & Cooling

These two processes occur simultaneously. When calculating the molding cycle, the longer of the two is considered. Typically, the cooling time includes the material storage duration.

Injection Pressure Holding Time

This duration is determined by the polymer’s properties, the product’s shape, and quality requirements such as appearance and dimensions. It’s influenced by factors like injection pressure, injection rate, screw rotation number, back pressure, and temperature.

Injection Process

Generally divided into three phases – slow, fast, and slow. The formula for estimation is:

T = W/20~50%V + t

Where:

- T: Total injection time

- W: Total injection volume (product weight x number of pieces + sprue weight)

- V: Maximum injection speed of the molding machine

- t: Time constant required for screw start and stop

Depending on the machine’s tonnage, the time constants vary: 80T200T takes 12s, 200T500T takes 23s, and 500T1000T takes 34s

Pressure Holding Time

This begins once the mold cavity is filled and lasts until the pressure holding ends. The duration is typically chosen based on the product’s appearance, shrinkage, dimensions, and deformation requirements.

Cooling Time

This refers to the time from the end of pressure holding to the mold opening. Factors influencing this duration include product shape, wall thickness, mold cooling water design, mold temperature, and melt properties.

Mold Opening & Closing Time

Influenced by machine size and mold structure. Mold core structures, mold rack transmission mechanisms, and three-plate mold mechanisms can all impact this time.

Product Ejection Time

Determined by ejection speed, ejection stroke, and ejection method (automatic, manual, or robotic). Automatic ejection is generally used for products with lower appearance requirements.

Optimizing the Injection Molding Cycle Time: Strategies for Efficiency

Reducing the injection molding cycle timeis a pivotal strategy for enhancing production efficiency and cutting down production costs. Below are targeted strategies aimed at each component.

Mold Opening and Closing Time Optimization

Mold closure typically has four phases: rapid closure, slow closure, low-pressure protection, and high-pressure lock. Mold opening usually consists of three stages: slow-fast-slow opening. By optimizing the speed and position, we can reduce this time. Newly designed injection molding machines come equipped with regenerative mold hydraulic circuits

Injection Time Optimization

Injection begins after the high-pressure lock completes.To avoid defects like bubbles or burns in the product, it’s advisable to use a high injection speed.

Pressure Holding Time Optimization

Pressure holding starts after injection. Its primary purpose is to compensate for shrinkage. Once the runner solidifies further pressure holding becomes redundant.

Cooling Time Optimization

The cooling time parameter on the injection molding machine is the duration from the end of pressure holding to the start of mold opening. This time is typically determined through experimentation

Material Storage Time Optimization

Material storage begins with the cooling time. If exceeds cooling time indicates insufficient plasticizing capacity. Methods to improve include:

- Using barrier screws

- Employing larger diameter screws

- Increasing groove depth

- Raising screw rotation speed (not suitable for shear-sensitive plastics)

- Using hydraulic nozzles

- Utilizing equipment that can plasticize throughout most of cycle

Locking Force Optimization

To prevent flash or excess material around use lowest possible locking force This extends lifespan of molds and tie bars.

Barrel Temperature Optimization

Ensuring smooth injection filling while using lowest possible barrel temperature can reduce cooling time.

Cooling Efficiency Optimization

Optimizing water channel design can enhance heat exchange efficiency. Using chilled water while ensuring quality further reduces cooling duration.

Ejection Time Optimization

For smaller injection molding machines with minimal ejection force pneumatic ejection can be used Independent hydraulic or electrical controls can enable simultaneous mold opening and ejection

FAQ

Q1: What factors most influence plastic injection molding cycle time?

A1: Key factors include material type, part geometry (especially wall thickness), cooling system design in molds, machine capabilities (e.g., speed), ejection method used (manual vs robotic), and environmental conditions.

Q2: How do I know if my cooling time is optimized?

A2: Begin with longer times then gradually decrease until parts eject without deformation. Monitor dimensional stability over multiple cycles.

Q3: Can automation help reduce cycle times?

A3: Yes. Robotic arms significantly reduce handling delays. Pneumatic or servo-driven systems further enhance timing control during ejection.

Q4: What role does mold design play in reducing cycle times?

A4: Efficient cooling channel layout shortens solidification; optimized parting lines simplify ejection; precision machining minimizes flash risk—each element contributes to faster cycles.

The Injection Molding Cycle Time Control Specialist:Silkbridge

If you’re seeking precision control over your plastic injection molding cycle time from concept to mass production—Silkbridge offers unmatched expertise.

At Silkbridge, we produce over 30 million plastic injection parts annually Our advanced machinery combined with rigorous quality control ensures that we meet diverse industry needs

From high-precision CNC machining to advanced EDM systems including Sodick linear motor technology—our tooling ensures molds are crafted to exact tolerances that support efficient cycles.

Our facilities house over 100 automated machines equipped with robotic arms enabling consistent output across high-volume runs.

Whether you require consumer-grade finish or medical-grade compliance—we deliver robust solutions that optimize every second of your plastic molding cycle.

Contact us to get the best offer for your products development and production

Let Silkbridge help you transform your ideas into high-performance products—efficiently manufactured with world-class precision.

For more information on developing and producing a new part or product, please contact Silkbridge on our business WhatsApp account https://wa.me/8618122838771 or call us on +86 8618122838771.