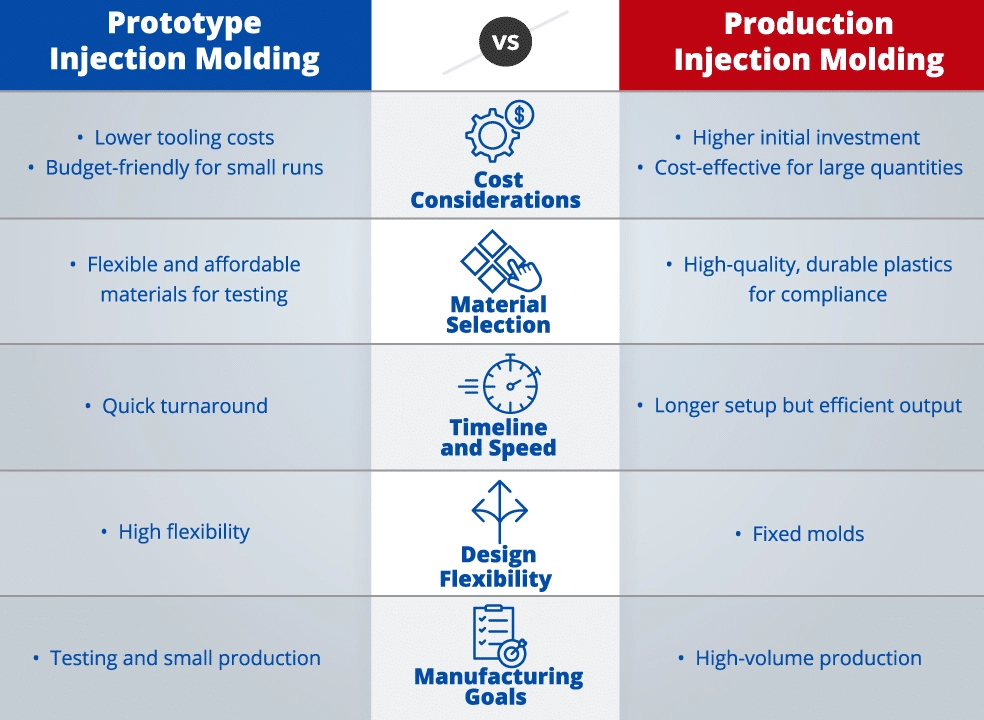

Plastic injection molding stays a key method for creating top-notch pieces in fields like consumer electronics, automotive, and medical devices. Yet, a usual wrong idea hangs around: getting plastic parts that match production needs means spending on costly, slow-to-make hardened-steel production molds only after the layout is completely set. This old way can slow down new ideas and raise spending.

The truth is much more lively. Just like 3D printing has changed early prototyping, prototype plastic injection molding gives a strong choice that connects basic ideas to full production. This way lets people make parts with the same shape and material traits as end items, so they can check designs early, do validation tests, and even run small trials. By using cheaper prototype molds, companies can change things quickly, lower chances of mistakes, and save a lot of money for amounts that go beyond what additive manufacturing can handle.

For suppliers like Silkbridge—a British-owned factory in China focusing on OEM and ODM plastic injection molding—these differences matter a great deal. They help provide exact components that follow European standards and aid worldwide growth.

First, What is Plastic Production Injection Molding?

Plastic production injection molding is a large-scale making method built for speed and steady results in forming the same parts. The steps start with warming plastic resin—usually thermoplastics such as ABS, polycarbonate, or nylon—until it turns into a thick, melted form. Workers then push this melt with strong force into a carefully made mold space that sets the part’s end look. After that, the stuff cools and hardens. Then, the mold opens, and the ready piece comes out. This loop happens fast, so it can produce thousands to millions of units in one go.

Production molding works best for growth, and it suits finished product plans where needs are clear. Fields like automotive count on it for tough pieces such as dashboard housings. Meanwhile, consumer electronics use it for covers that need close fits and nice looks.

Designing and Constructing Production Molds

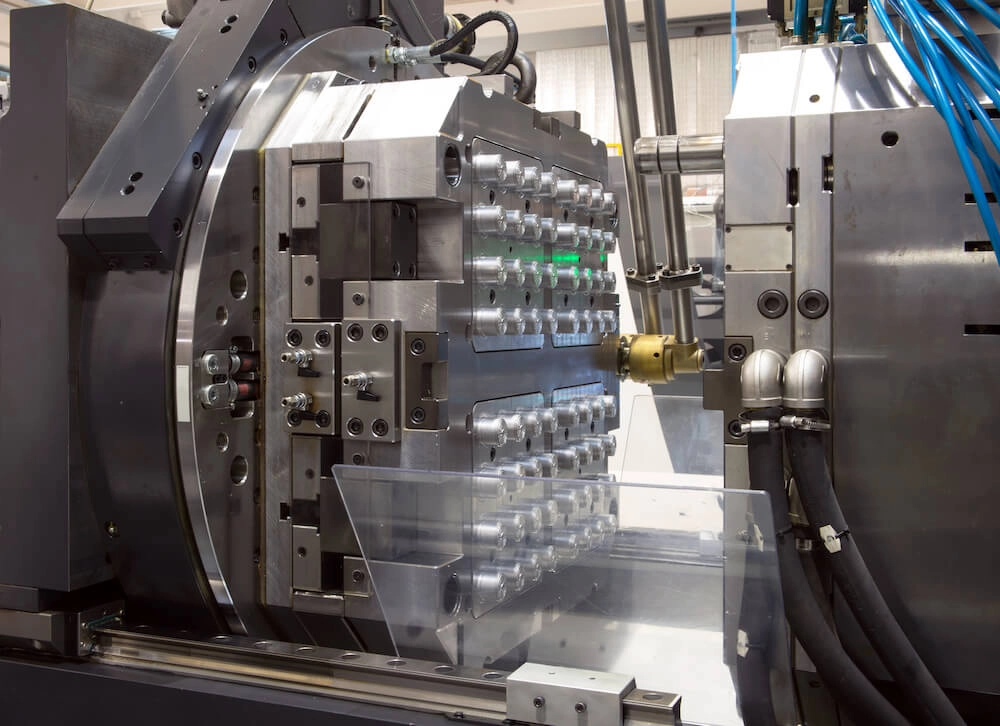

Production molds are made to last long. Workers often cut them from very tough P20 or H13 tool steel. This pick handles heat pressures from many cycles—tens or hundreds of thousands—without much damage. The building steps include computer-aided design (CAD). After that comes CNC machining, electrical discharge machining (EDM), and polishing. These achieve smooth surfaces that show right on part quality.

At places like those run by Silkbridge, more than 30 CNC machines and 25 EDM units make sure molds hit micron-level exactness. They support yearly output of over 30 million plastic parts through 100 injection machines from 180 to 1200 tons.

The Impact of Mold Complexity on Production

Mold complexity affects wait times and what is possible right away. Hardened steel’s stiffness means workers must take away material in small steps to stop tool breaks. This stretches making from 5 to 16 weeks based on shape. Bigger parts with undercuts or fine details—like threads or ribs—need smaller end mills. That makes the schedule even longer.

Advanced production molds add side-action parts like slides and lifters. These form features at right angles to the mold’s opening path. When grown to multi-cavity setups (for example, 16 or 32 cavities), these parts increase difficulty. They require careful checks with software like Moldflow. This predicts flow, cooling, and warp.

Cost-Optimization Strategies with Production Molds

Cost savings in production molding depend on lowering each part’s price, where cycle time matters most. A normal cycle covers mold closing, injection, cooling, and ejection—often under 60 seconds for tuned tools. Molds have shaped cooling paths and multi-cavity plans to speed this up. They also include automatic ejection systems.

For example, a single-cavity mold at $2 per minute gives parts at $2 each if the cycle takes one minute. A 4-cavity type cuts this to $0.50. It boosts savings at amounts over 10,000 units.

What is Prototype Injection Molding?

Prototype injection molding copies production in material choices and basic steps. But it differs in tool building and size. It uses the same resins and injection settings to create parts that look and work just like production ones in shape, fit, and use. The main differences are in mold materials—aluminum or pre-hardened steel—and single-cavity plans. These focus on quickness and changes over lasting long.

This method helps key steps like design checks, strength tests, and market checks. It lets makers improve versions before going to large tooling. Gains include faster schedules, less starting money, and easy growth.

Key Benefits of Prototype Injection Molding

Fast Turnaround: Prototype molds get made in 1-2 weeks, compared to months for production. This lets parts appear in days for quick tests.

Cost-Effective for Low Volumes: Tooling costs go from $6,000 to $15,000. It fits runs under 10,000 units and skips wasted production space.

Production-Equivalent Parts: Same materials give true performance info, from pull strength to heat growth. This matters for rules in medical or automotive uses.

Early Design Verification and Validation: Parts face real stress tests—like drop checks or bio assays. They spot problems before production.

Versatile Materials and Finishes: Handles many resins, including TPEs for soft grips. Options include texturing or EMI shielding.

Smooth Transition to Production: Prototype tools fill gaps during final mold work. They supply parts for shows or beta tests.

Rapid Tooling Techniques: CNC-machined aluminum allows fast fixes. Lifespans reach 10,000-50,000 shots.

Limitations: Longer cycles from hand work and basic cooling raise part costs for huge amounts. Complex shapes may need trade-offs.

Silkbridge shows these gains well. It offers single-cavity prototypes that change in days—even for non-metal-safe tweaks—while keeping exactness for fields like consumer electronics.

Material Selection for Prototype Molds

Prototype molds pick softer metals like aluminum or brass for easy cutting. These cut 3-5 times quicker than hardened steel. They shorten wait times and costs but keep starting exactness. A cared-for aluminum mold can give tens of thousands of shots. It holds tolerances within ±0.005 inches for most shapes.

Resin choices stay wide, from common plastics to high grades like PEEK for hot uses.

Prototype Injection Molding Flexibility

Single-cavity plans boost changes. Design fixes—like tweaking snap fits or wall sizes—need changes to just one cavity. This cuts stop times. Metal-safe changes (adding stuff) use easy milling. Non-metal-safe ones (taking away stuff) use insert plugs. These are much simpler in softer metals.

This bendiness helps a lot in step-by-step growth. Feedback from use tests leads to improvements. In comparison, multi-cavity production tools need matched updates. That raises costs.

Simplifying the Molding Process with Prototype Molding

Prototype tools skip automatic side actions. They choose hand core pins or pickouts put in before injection. After ejection, workers take them out. This lengthens cycles but cuts tool costs a lot—often 70-80% less than production ones. Without built-in cooling lines, room air or simple water paths work. Still, skilled workers tune fill speeds to skip flaws like short shots.

This simple way fits small needs, from user tests to overmolded groups with metal inserts.

When to Choose Prototype Tooling Over Production Tooling

Prototype molding stands out in cases needing quick moves:

Quick part needs for trade shows or investor views.

Designs not final and likely to change.

Material checks, like ABS versus polycarbonate for strength.

Step-by-step features like seals or living hinges.

After 3D print stages where additive limits show.

Rule tests on true samples.

Bendy TPE/TPU parts for grips or overmolding.

Small batches for market input.

Complex groups with inserts.

Jobs where production amounts do not support full tooling.

For manufacturers, picking prototype tooling lowers dangers. Silkbridge’s quick changes prove this for global OEMs.

FAQs in Relation to Differences Between Prototype and Production Molding

What is the difference between production and prototype?

A prototype acts as an early model for checks and improvements. Production means making final items in big numbers after checks.

What is the difference between prototype and production parts?

Prototype parts aim at early checks and changes. Production parts get tuned for large making after design approval.

What is the difference between a prototype tool and a production tool?

A production tool uses hardened tool steel for large runs. It often has multiple cavities and automated parts. A prototype tool picks aluminum or brass for fast, small-scale making. It is usually single-cavity with hand features.

What is prototype molding?

Prototype molding means plastic injection molding with special tools for quick, small-group output to aid design growth.

Partner with a Trusted Plastic Injection Molding Manufacturer and Supplier for Scalable Prototyping Solutions

As a top plastic injection molding manufacturer, supplier, and factory, Silkbridge gives full answers from prototype tooling to large production. It mixes British exactness with Chinese speed. With over 100 injection machines, strong CNC/EDM skills, and ISO 9001 certification, Silkbridge meets OEM/ODM needs in electronics, automotive, and medical areas. It makes 30 million+ parts each year at good prices.

Companies wanting to ease growth should ask for a quote now for prototype molding help. Reach Silkbridge by WhatsApp at +86 18122838771 or contact@silkbridgeltd.com to talk custom needs, get design advice, and speed your way to market.