In the current quick-moving product creation world, quickness and exactness are must-haves. Rapid injection molding (RIM) has become a strong method for firms that want to shift from sample to full making fast — and Silkbridge, with its complete manufacturing setup, is ready to provide.

What Is Rapid Injection Molding (RIM)?

Rapid injection molding is the way of making parts with molds that get cut swiftly (often from aluminum) instead of usual steel molds. This approach cuts down wait time. It lets companies tweak designs and check how they work without the high price or hold-up of normal tooling. With RIM, parts ready for making come out sooner. This aids product groups to test, improve, and start products more smoothly.

Why RIM Matters for Time-to-Market

- Speed: Since aluminum molds get machined quicker, tooling finishes much sooner.

- Flexibility: Creators can adjust and repeat, helped by Silkbridge’s DFM (Design for Manufacturing) advice.

- Cost Efficiency: Cheaper tooling costs plus the option to make small-to-medium amounts suit RIM well for bridge making or brief runs.

- Scalability: After the design gets checked, Silkbridge can grow into standard making, using its big group of injection machines.

How Rapid Injection Molding Works at Silkbridge

Silkbridge mixes Western design ideas and Chinese making rules to give a smooth RIM process. Here is a simple step-by-step look at how they do it:

- Design & DFM Analysis Silkbridge’s own R&D group—made up of more than 20 engineers and creators from Western Europe and China—gives key design help.

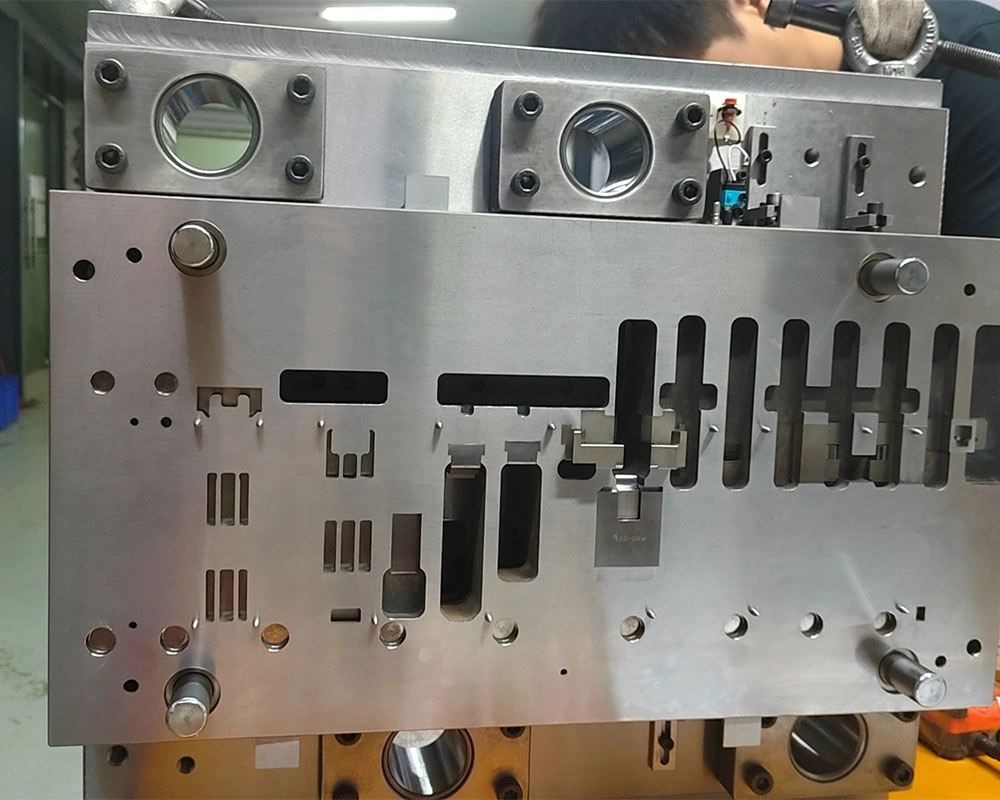

- Mold Making Molds get built with over 30 CNC machines and 25 EDM units. This ensures close limits and great accuracy.

- Injection Molding With 100 molding machines from 180 to 1200 tons, Silkbridge creates over 30 million plastic parts each year.

- Post-Processing & Quality Control Once parts are shaped, they go through strict quality tests. These include a planned multi-step QC system to keep things steady.

- Assembly & Distribution Since Silkbridge is also a turnkey electronics manufacturer, they can fit molded parts into complete items (PCB development, assembly, packaging). They also manage worldwide shipping under Delivered Duty Paid (DDP) terms.

Applications: Where Rapid Injection Molding Excels

Rapid injection molding can help many fields. Here are some main areas where Silkbridge uses its RIM skills:

Medical

Silkbridge makes medical-grade injection molded parts in a clean, managed space. SilkBridge Their medical molding skills include using biocompatible materials (e.g., polypropylene, polycarbonate, silicone) to build items like syringes, diagnostic devices, and surgical parts.

Automotive

Silkbridge’s high-tonnage machines (up to 1200 tons) let them create big molded automotive pieces, such as dashboards, panels, and other strong parts. SilkBridge The accuracy and repeat of injection molding are very useful in automotive. There, close limits count for safety and fitting.

Consumer Electronics

In consumer electronics, exact plastic covers and cases are needed. Silkbridge’s full ability—from mold-making to end assembly—makes it simpler to test and make covers, inner fittings, and over-molded pieces.

Industrial Equipment

Strong, high-accuracy pieces for industrial machines often need large, tough molded parts. Silkbridge’s skill for oversized injection molding helps such uses.

Materials & Resources

Silkbridge’s material knowledge covers a wide range to fit work, rule, and show needs:

- Thermoplastics: Usual work plastics, including polypropylene (PP), polyethylene (PE), and polycarbonate (PC).

- Silicones & Elastomers: Good for soft-feel parts, bendy pieces, or medical items.

- Medical-Grade Polymers: Safe with body, can-be-cleaned plastics for health uses.

- To ensure each part hits design and quality aims, Silkbridge gives strict design checks and advice early on. This helps to best wall thicknesses, gate spots, and draft angles.

Industries Served by Silkbridge

Silkbridge’s joined making model helps many fields:

- Medical Devices: From syringes to diagnostics.

- Automotive: Large strong parts and covers.

- Consumer Electronics: Plastic cases, inner strong parts, over-molded items.

- Industrial & Construction: High-strength molded parts used in machines, covers, and buildings.

Why Silkbridge Is the Right Partner for Rapid Injection Molding

There are many good reasons why a manufacturer or supplier would pick Silkbridge for RIM:

- End-to-End Capability Silkbridge gives a full, joined answer—from product design and testing, to mold-making, injection molding, assembly, and world shipping.

- Precision & Scale With close limits (down to 0.01 mm) and 100 injection machines, Silkbridge brings both accuracy and high amount.

- Quality Assurance They keep a multi-step quality control system. Their medical part making happens in a closed, clean space.

- Cost Efficiency & Flexibility Using rapid tooling (often aluminum molds) lowers cost and shortens wait times. This makes it great for short-run or bridge making.

- Global Distribution & Logistics Silkbridge offers DDP shipping. They handle moving, customs, and duties for clients in the USA, Europe, Japan, and more.

- Proven Expertise Started by a British designer in 2014, Silkbridge mixes Western new ideas with Chinese making. SilkBridge Their proofs and ISO certifications make them a reliable B2B partner.

Challenges & Considerations in RIM

Though rapid injection molding has many pluses, there are some downsides to know:

- Tool Longevity: Aluminum molds (usual in RIM) may wear quicker than steel molds, mainly in very high-amount making.

- Material Constraints: Some high-heat or special materials may need steel tooling rather than aluminum.

- Design Optimization: For rapid tooling to work well, early design-for-manufacturing advice is key—items like wall thickness and draft count.

- Quality Tradeoffs: Since aluminum molds are less strong, limits may shift a bit over time if not watched.

- Silkbridge handles these issues with its design-check process and own engineering group. This ensures parts get best from the start and tools get built right.

Sustainable and Responsible Manufacturing

Silkbridge focuses hard on green ways in its work:

- Waste Reduction: Auto systems and close process watch help cut material loss.

- Efficiency: Their joined site cuts the need to shift parts between vendors. This lowers gas release and wait times.

- Quality Over Rework: Strict QC at each step cuts the chance of redo or faults. This saves materials and resources more.

FAQ

Q1: What is the typical lead time for rapid injection molding at Silkbridge?

Though exact wait times rely on the design, part size, and hardness, using rapid tooling (like aluminum molds) speeds up tooling and part making.

Q2: What parts volumes are suitable for RIM?

Rapid injection molding is very cost-good for low- to medium-amount runs, testing, or bridge making.

Q3: Can Silkbridge handle medical-grade components?

Yes. Silkbridge keeps a special, closed making space for medical-grade injection molding using materials like polypropylene, polycarbonate, and silicone.

Q4: What materials are supported?

Silkbridge supports many thermoplastics (e.g., PP, PE, PC) and elastomers like silicone.

Q5: Do they offer assembly and full product manufacturing?

Yes — Silkbridge offers turnkey electronics manufacturing, including PCB assembly, product joining, and end packaging.

Q6: How does Silkbridge ship globally?

They give DDP (Delivered Duty Paid) moving, handling customs, duties, and shipment for clients worldwide.

Call to Action: Partner with Silkbridge — Your Reliable Manufacturer & Supplier

If a quick, exact, and full rapid injection molding answer is what your firm needs, Silkbridge offers a matchless mix of:

- Rapid tooling and quick turnaround

- High-volume injection ability (180–1200 ton machines)

- In-house design, mold-making, and assembly

- Global moving and DDP distribution

Get in touch now to start a talk with Silkbridge’s group of engineers and supply chain experts. As a trusted manufacturer, supplier, and one-stop factory, Silkbridge is set to help take your product from idea to market with quickness, quality, and sureness.

- Email: contact@silkbridgeltd.com

- WhatsApp / Phone: +86 18122838771

Let Silkbridge be your key making partner for next-level product growth and injection molded making.