What is Toy Injection Molding?

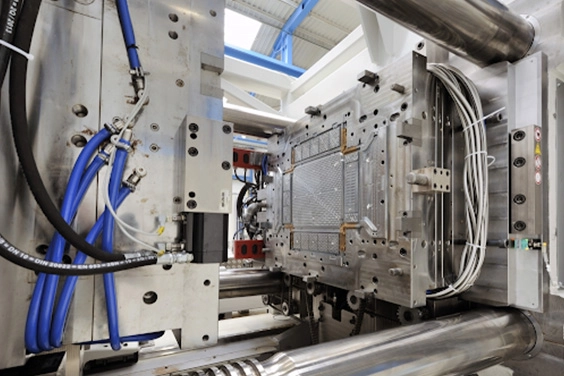

Toy injection molding is a fast way to make plastic toy parts. It turns plastic pellets into exact, bright, and strong pieces. The process has four main steps. Each step is set up for speed and quality. First, thermoplastic pellets get heated until they melt. Then, the melted plastic is pushed hard into a metal mold. The mold is shaped just right. After the plastic fills the mold, it cools and hardens. Finally, the mold opens, and the toy part pops out.

This method makes lots of identical parts with fine details. It’s perfect for the toy industry.

Why Choose Plastic Injection Molding for Toy Manufacturing?

Plastic injection molding is the top choice for making plastic toys. It has many benefits.

- Safety: Uses safe, BPA-free materials like ABS and PP. These meet global safety rules like ASTM F963 and EN71. This keeps kids safe during play.

- Bright Designs: Makes colorful, fun toys with multi-color molding or techniques like spray painting or pad printing. These boost play and creativity for toys like Barbie dolls or molding toy sets.

- Cost-Effectiveness: Great for making lots of toys. It lowers the cost per toy. The starting cost for plastic toy moulds is balanced by high output. This makes toys affordable.

- Precision and Complexity: Creates detailed designs with tight fits, like the interlocking parts of injection molding LEGO bricks or action figures. This ensures perfect performance.

- Thin-Wall Structures: Makes light, strong toys with thin walls. This uses less material but keeps durability.

- Material Choices: Offers many thermoplastics, from bendy PP to eco-friendly PLA.

- Sustainability: Uses recyclable plastics, up to 30% recycled content, and low-waste methods.

Common Plastic Materials Used in Plastic Toys: Colors and Properties

Overview of Plastics Commonly Used in Toys

Toy injection molding uses different plastics. Each is picked for safety, strength, light weight, and bright colors.

ABS (Acrylonitrile Butadiene Styrene)

ABS takes color well and keeps it over time. It’s safe and BPA-free. It’s tough, resists impacts, and has a nice surface. It’s the top choice for durable toys like LEGO bricks.

PP (Polypropylene)

PP holds bright colors, even in sunlight. It’s safe and light. It bends well and resists chemicals and wear. It’s great for bath toys and toy containers.

PE (Polyethylene)

PE takes bright or see-through colors. It’s BPA-free and resists impacts. LDPE is bendy; HDPE is stiff. It’s used for teething rings and outdoor playsets.

PVC (Polyvinyl Chloride)

PVC holds vivid colors and detailed textures. It can be stiff or soft. It’s common in action figures and inflatable toys.

Color Additives and Pigmentation Techniques

Bright designs come from multi-color molding, like spray painting or pad printing. These make toys look fun and match brand styles. Kids love the appealing look.

Mechanical and Safety Properties of Each Material

Each material meets strict safety standards:

- ABS is great for impact resistance.

- PP bends without breaking.

- PE is soft for baby toys.

- PVC can be soft or hard, depending on the toy.

All are BPA-free and follow ASTM F963 or EN71 rules.

Impact of Mold Design on Toy Injection Molding Quality

Importance of Precision in Mold Engineering

The mold design shapes toy quality. Plastic molded toys have fine details and bright colors. Even small errors can mess up the look. Mold precision is super important.

Factors That Affect Mold Performance and Final Product Quality

Gate Location and Flow Path Optimization

Good gate placement ensures melted plastic flows evenly in the mold. Bad placement can cause short fills or warping.

Venting, Cooling, and Ejection Systems

Even cooling stops toy deformation. It keeps quality steady across big production runs.

Influence on Surface Finish and Dimensional Accuracy

For toys needing a shiny look, top steels like S136(H) or 2083 give great finishes and last long. Mold polishing also helps get glossy surfaces for consumer toys.

Typical Applications of Injection-Molded Toys

Types of Toys Produced Using Injection Molding

Action Figures and Dolls

Injection molding makes detailed features for dolls or movable joints for action figures.

Building Blocks and Construction Sets

LEGO bricks are a great example. They need exact interlocking precision, which this method delivers.

Educational Toys and Puzzles

STEM kits need parts that fit perfectly. Precise tooling makes this possible.

Vehicle Models and Playsets

Car bodies or dollhouse parts need stable molds for perfect assembly.

Market Trends in Plastic Toy Categories

Eco-friendly plastics like PLA are growing popular as people care more about sustainability. Multi-material toys using over-molding are also trending.

Quality and Safety Standards in the Toy Manufacturing

Safety is key in toy injection molding. Main standards include:

- ASTM F963 (USA): Covers safe materials, no sharp edges, and durability for North America.

- EN71 (Europe): Checks chemicals, fire safety, and physical traits. It’s required in Europe.

- ISO 8124 (International): Sets global rules for material safety and design. Many countries use it.

Silkbridge Expertise in Toy Injection Molding

Silkbridge offers top precision with advanced tools:

Their facility has over 30 CNC machines and 25 EDM units, including Sodick models. These are great for sharp corners and deep molds needed for complex toys.

Mold-making at Silkbridge hits tolerances of 0.01 mm (0.0004 inches). This ensures steady results for high-volume toy production worldwide.

They provide over-molding for complex parts, like soft grips with hard bodies, perfect for educational or interactive toys.

With robotic automation on over 100 injection machines (180–1200 tons), Silkbridge ensures fast production. They maintain strict quality control, from raw materials to final checks using CMMs and optical comparators.

For more information on developing and producing a new part or product, please contact Silkbridge on our business WhatsApp account https://wa.me/8618122838771 or call us on +86 8618122838771.