Overview of TPU and TPE

What is TPU (Thermoplastic Polyurethane)?

Thermoplastic Polyurethane, or TPU, is a handy material that mixes traits of plastic and rubber. It’s known for being super strong, stretchy, and tough against scratches and chemicals. TPU has been a go-to choice in many fields since BF Goodrich created it in 1959. You’ll find it in cars, planes, medical tools, and consumer goods like phone cases. Plus, TPU works well with methods like Fused Deposition Modeling (FDM) or Selective Laser Sintering (SLS). This makes it great for different kinds of manufacturing. One cool thing about TPU is you can tweak its hardness. So, it can feel soft like rubber or hard like plastic.

What is TPE (Thermoplastic Elastomer)?

Thermoplastic Elastomer, or TPE, is a material that blends plastic and stretchy rubber qualities. It’s soft and bendy, which makes it a favorite for many uses since the 1950s. TPE shows up in items needing a gentle touch, like grips, seals, or medical gear. Its low melting point makes it easy to shape compared to other materials. Also, TPE is budget-friendly and easy to find. That’s why it’s popular for light and flexible designs.

Shared Traits of TPU and TPE

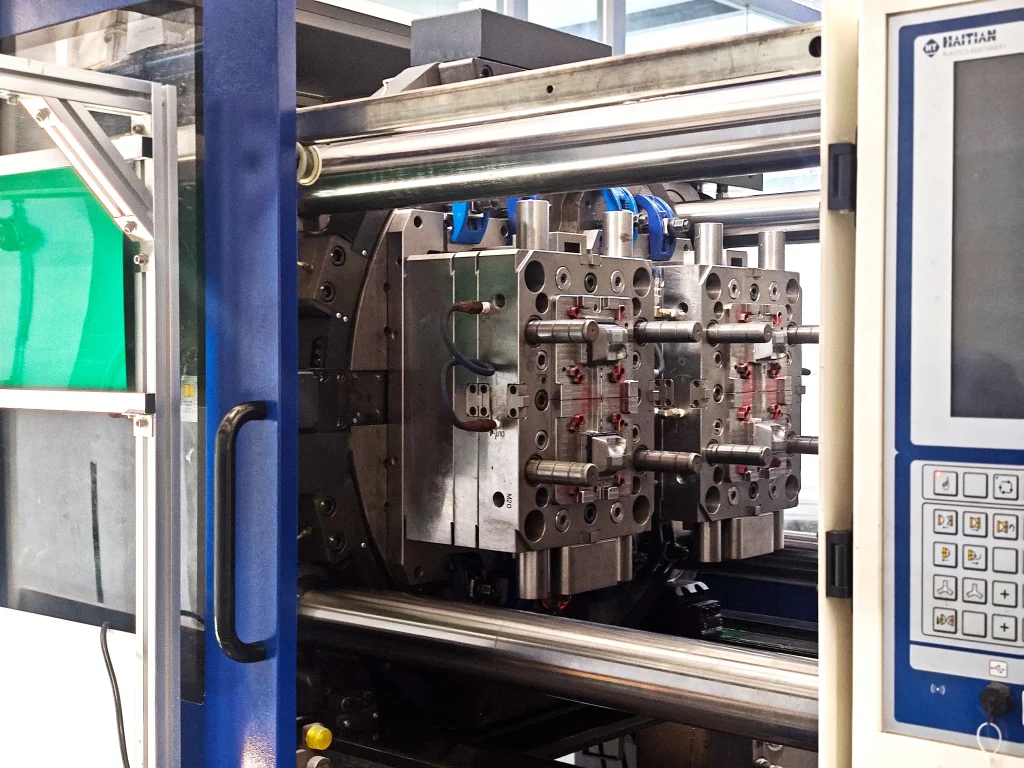

TPU and TPE have a lot in common as part of the thermoplastic elastomer group. Both are stretchy, tough, and can be recycled. They stand up to water and sunlight and handle impacts well. Also, both work great for Injection molding processes.

Comparing Material Properties

Mechanical Features of TPU and TPE

Strength and Toughness

TPU beats TPE when it comes to strength and staying power. It resists scratches better, so it’s perfect for heavy-duty uses like car parts or industrial tools. On the other hand, TPE has decent strength but shines in being super bendy.

Bendiness and Stretch

TPE is softer and more flexible than TPU. This makes it great for products needing lots of stretch, like seals or grips. TPU is stretchy too, even under pressure, but it’s a bit stiffer than TPE.

Heat-Related Properties of TPU vs. TPE

Handling Heat

Both TPU and TPE deal with heat pretty well. But TPU holds up better in really hot conditions because it stays stable. This makes TPU a good pick for items facing high temperatures.

Acting in Cold Weather

TPU keeps its stretchy nature even when it’s freezing. TPE, however, might get less bendy in cold settings. So, TPU has an advantage in chilly places.

Resistance to Chemicals

TPU is tougher against oils, greases, and solvents than TPE. This makes it awesome for rough settings, like in cars or factories. TPE resists chemicals okay but might wear out faster when facing harsh stuff.

Uses in Injection Molding

How TPU is Used in Injection Molding

Industrial Purposes

TPU’s strength makes it ideal for industrial items like conveyor belts, seals, gaskets, and protective layers. It lasts long because it handles wear and tear so well.

Making Consumer Goods

In consumer goods, TPU is popular for phone cases, sports gear like shoe soles, or wire coverings for electronics. Its toughness and smooth look make it a great fit.

How TPE is Used in Injection Molding

Medical Uses

TPE’s softness and safety for human use make it perfect for medical tools like tubes or mouthpieces. Its ease of shaping helps create detailed designs for healthcare products.

Car Parts Production

In cars, TPE is often used for airbag covers or interior bits like handles. Its flexibility and low cost make it a smart choice.

At Silkbridge’s top-notch facility, we have over 30 CNC machines and 25 EDM units. We focus on precision Injection molding services to meet all kinds of industry needs. Our skills cover everything from designing products to assembling them. We ensure top quality while using advanced materials like TPU and TPE for various projects.

Pros and Cons of Each Material

Why TPU is Great for Injection Molding

TPU has lots of perks that make it a top choice for Injection molding in many fields. Its awesome resistance to scratches means it lasts a long time, especially for car parts or industrial tools. TPU stays stretchy even in cold weather, which is great for chilly environments. Also, you can adjust TPU’s hardness to make products feel soft like rubber or stiff like plastic. Its strong defense against chemicals like oils and solvents makes it super useful in tough settings. Plus, TPU gives a sleek, smooth finish. This looks nice and works well for consumer goods like phone cases or sports equipment.

TPU’s Downsides in Some Cases

Even with its strengths, TPU has some drawbacks. It soaks up moisture from the air, which can make storage and processing tricky. Shaping or finishing TPU after molding is tough because it resists scratches and chemicals so well. These traits are great for the final product but make manufacturing harder. Also, TPU costs more than TPE, which might not work for projects with tight budgets.

Why TPE is Good for Certain Projects

TPE stands out when softness and flexibility are key. Its lower melting point makes molding easier, which cuts down on energy use and complexity. TPE is cheaper, so it’s great for big projects or consumer goods where saving money matters. Its rubbery feel offers a comfy grip, perfect for handles or seals. Also, TPE is easier to recycle than TPU, which helps with eco-friendly goals.

TPE’s Challenges

TPE has its own issues. It tends to shrink more, which makes it hard to get exact sizes during manufacturing. It’s also less tough against chemicals and scratches compared to TPU. This limits its use in harsh settings. Plus, getting the best results with TPE in 3D printing needs precise settings, which can be tough for beginners.

Cost Differences for TPU vs. TPE

Price Gaps Between the Two

The cost of TPU and TPE affects which one you pick. TPE is usually cheaper, starting at about $40 per kg, while TPU costs around $45 per kg or more. This price difference makes TPE a go-to for projects where saving money is key.

Long-Term Savings Based on Use

Even though TPU costs more upfront, its toughness and resistance to wear can save money over time. You won’t need to fix or replace parts as often. Meanwhile, TPE’s lower starting cost makes it better for short-term projects or items that don’t need to handle tough conditions.

Things to Think About When Choosing TPU or TPE

Performance Needs for the Final Product

Picking between TPU and TPE depends on what your project needs. If you need strong, scratch-resistant, or chemical-proof materials—like for car parts or industrial tools—TPU is usually better. But if flexibility and comfort are more important—like for grips or medical devices—TPE might be the way to go.

Environmental and Eco-Friendly Concerns

Both TPU and TPE can be recycled, but they impact the environment differently during production and disposal. TPE is easier to recycle, giving it a slight edge for eco-conscious projects. However, new recycling tech is making both materials more planet-friendly over time.

Looks and Style in Product Design

How a product looks matters a lot in design choices. TPU has a smoother finish than TPE, which makes it better for consumer goods like electronic cases or sports gear where appearance is a big deal.

At Silkbridge’s high-tech manufacturing hub, we use over 30 CNC machines and 25 EDM units to offer precise Injection molding services. We tailor our work to meet various industry demands. Our expertise with materials like TPU and TPE ensures your projects perform at their best while meeting strict quality standards.

- WhatsApp: +86 18122838771

- Phone: +86 18122838771

- Email:contact@silkbridgeltd.com