In the highly dynamic electronics sector, manufacturers and brand companies often deploy different production models—namely ODM (Original Design Manufacturer), OEM (Original Equipment Manufacturer), and EMS (Electronics Manufacturing Services). Each model offers distinct advantages and suits specific strategic aims in product development, design ownership, cost and time-to-market. This guide maps out these models and explains how a full‐service manufacturing partner such as Silkbridge can support brand companies and OEM/ODM clients.

01 – ODM

An ODM is a partner that not only manufactures but also designs the product. Historically, many OEMs focused purely on production; design and branding were managed by the brand owner. Over time, manufacturers realised that margins on pure production were slim and began expanding upstream into design. Some Independent Design Houses (IDHs) also moved downstream into manufacturing and became ODMs. Brand owners often turn to ODMs when rapid expansion into new product lines is needed—they outsource both design and production to streamline development.

Once an ODM completes a design, other brands may request the same platform under their own badge—depending on whether exclusivity was agreed. Today’s ODMs offer one-stop solutions combining design, manufacturing, sourcing, and, in many cases, global logistics.

Key aspects of ODM:

Design ownership by the manufacturer (ODMs hold IP or grant rights)

Brand company focuses on marketing and distribution

Faster time-to-market for new SKUs and variant launches

Lower design investment by the brand owner

02 – OEM

An OEM is a production partner contracted to manufacture products designed by the brand company—meaning the brand retains design IP and controls product development, while the OEM focuses on manufacturing, quality control, and often assembly or sourcing.

Well-known large brands such as Microsoft, IBM, HP and Compaq use OEM partnerships to reduce fixed assets and overhead. The OEM must meet the brand’s quality, reliability and regulatory standards, often involving rigorous production checks.

Key attributes of OEM:

Brand owns product design and IP

OEM provides manufacturing capacity, materials procurement, and production expertise

Suitable where the brand wants design control but outsources production

Requires close process monitoring, QA/QC and strong logistics alignment

03 – EMS

EMS providers deliver a full‐spectrum service beyond mere manufacturing. These firms manage procurement, manufacturing, assembly, testing, sometimes logistics and after‐sales support for electronics brand companies. Globally, “EMS” is the umbrella term for contract manufacturing in electronics; in China and Taiwan the term often overlaps with OEM.

EMS providers support companies by handling end-to-end lifecycle: from design input through manufacturing, testing and shipping. For brand companies with limited manufacturing expertise or those seeking outsourced innovation, EMS is a compelling model.

Key features of EMS:

Full lifecycle management: design support, procurement, production, test, logistics

Scalable global capacity

Often serves multiple brands, using best-practice manufacturing

Enables brands to focus on marketing, channels and service

How to Choose Between ODM, OEM and EMS for Electronics Production

Selecting the right manufacturing model depends on strategic objectives, cost constraints, time-to-market and design ownership. Here are some guiding questions a brand or product owner can ask:

Design control: Does the brand want full ownership of IP (favoring OEM) or is it comfortable with the manufacturer handling design (ODMs)?

Speed and flexibility: If rapid product launching or many variants is required, ODM or EMS may provide faster ramp-up.

Cost structure: OEM may cost more upfront (designing, tooling), but offers IP control. ODM or EMS may reduce brand investment but involve shared IP or less exclusivity.

Scale and complexity: For high‐volume, low-mix manufacturing, OEM works well. For frequent product changes, variant SKUs or high service integration—EMS or ODM may be better.

Supply chain and logistics: Do you need global manufacturing footprint, inventory/fulfilment support, aftermarket care? EMS providers excel in that.

Risk and compliance: For regulated markets (medical, automotive), ensure the partner meets required certifications and quality standards regardless of model.

Silkbridge – Manufacturer, Supplier & Factory Capabilities

Silkbridge presents a compelling choice for brands seeking a flexible manufacturing partner across OEM, ODM and EMS models. Key strengths include:

Founded with a vision to combine European design ethos with Chinese manufacturing efficiency.

Offers plastic injection moulding, PCB development/production, electronic product assembly and full turnkey solutions.

Operates more than 30 CNC machines and 25 EDM units for mould fabrication—an indication of strong in-house tooling capability.

Handles production with 100 injection-moulding machines ranging from 180-ton to 1200-ton tonnage, robotic automation, temperature/humidity controlled rooms—demonstrating scalability for high-volume runs.

Acts as both manufacturer and supplier, enabling B2B partners to receive direct factory pricing, streamlined logistics and customised manufacturing.

Capable of supporting OEM (brand owns design, Silkbridge manufactures), ODM (Silkbridge designs + manufactures) and EMS (turnkey services, assembly, logistics).

For electronics brands or startup product companies seeking manufacturing partners who can flex across models, Silkbridge embodies the “manufacturer / supplier / factory” model critical in B2B engagements.

Comparing the Models: At a Glance

| Model | Design Ownership | Brand Control | Best For | Examples of Silkbridge Fit |

|---|---|---|---|---|

| ODM | Manufacturer designs | Brand focuses on marketing | Rapid launches, multiple variants | Silkbridge offers design + production |

| OEM | Brand designs, outsources manufacturing | Brand full control of IP | High volume, proven design | Brands give Silkbridge specs for manufacturing |

| EMS | Manufacturer/contractor offers full lifecycle | Brand handles sales/marketing | Complex supply chain, service needs | Silkbridge integrates injection moulding + PCB + assembly |

Conclusion

In today’s electronics ecosystem, clarifying manufacturing model—ODM, OEM or EMS—is critical for cost, speed, IP control and scalability. For brands and product owners seeking a trusted factory partner, Silkbridge stands out as a full-service manufacturer, supplier and factory capable of supporting all three models. Whether the need is for design innovation (ODM), pure manufacturing (OEM) or end‐to‐end lifecycle services (EMS), aligning with a capable partner offers strategic advantage.

FAQ

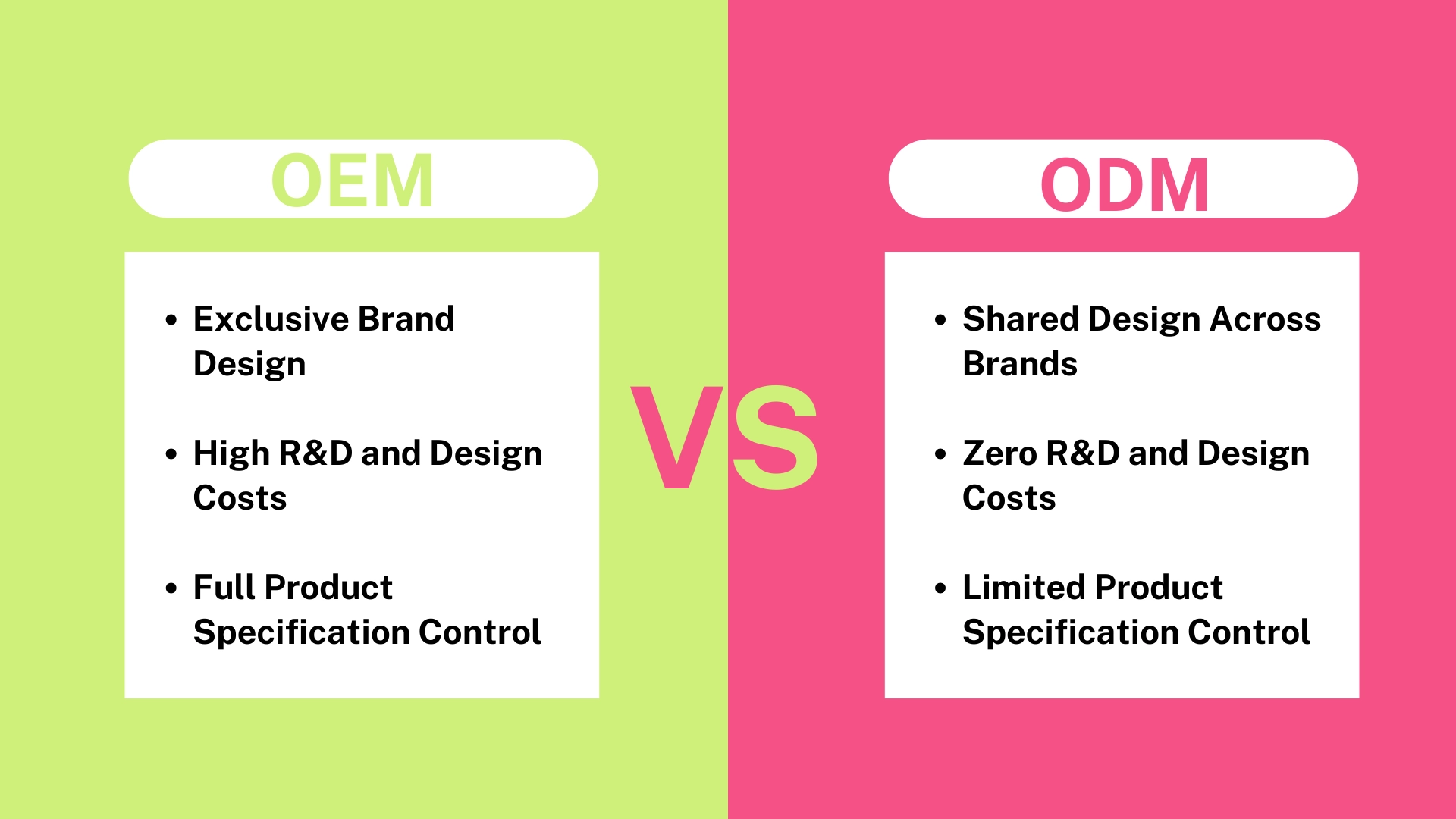

Q1: What is the main difference between ODM and OEM?

ODM means the manufacturer handles product design and manufacturing. OEM means the brand owns design and outsources production to the manufacturer.

Q2: What does EMS cover that OEM doesn’t?

EMS provides end-to-end services including procurement, manufacturing, testing, logistics and sometimes after-sales support—beyond just production.

Q3: How do I know whether to choose ODM, OEM or EMS for my product?

It depends on design ownership desires, time-to-market speed, cost constraints, and whether you need manufacturing only (OEM), design + manufacturing (ODM), or full lifecycle services (EMS).

Q4: What capabilities should I look for in a manufacturing partner?

Look for tooling capacity (CNC, EDM), manufacturing scale (machines, tonnage), automation, clean room or controlled environments (if required), certifications (e.g., ISO 9001) and ability to serve as manufacturer, supplier and factory.

Q5: Can one manufacturer support all three models (ODM, OEM, EMS)?

Yes—manufacturers like Silkbridge can flex across models depending on client needs, offering design services, manufacturing only or full turnkey service with Assembly and logistics.

Partner with Silkbridge – Your Electronics Manufacturing Manufacturer & Supplier

For electronics brands, product developers and OEM/ODM partners seeking a reliable factory for injection moulding, PCB development, product assembly and full lifecycle manufacturing—Silkbridge offers the manufacturer, supplier and factory capabilities needed. Get a custom quote, review tooling and production strategies, and start scaling your product line with confidence. Contact Silkbridge today to discuss your next project.