Sprues, runners, and gates in an injection mold are like hallways and doors from the nozzle to the mold cavity. So, how do they work?

Introduction

Plastic injection molding is a key part of making things today. It’s used for stuff like tiny medical tools or strong car parts. This process is fast and can make lots of exact, identical pieces. But the melted plastic doesn’t just go straight from the machine to the mold cavity. It travels through a system of sprues, runners, and gates. These parts make sure the plastic flows evenly, cuts down on mistakes, and lets you make many parts in one mold. In this article, we’ll talk about what sprues, runners, and gates do, their types, and how they affect injection molding.

In Short:

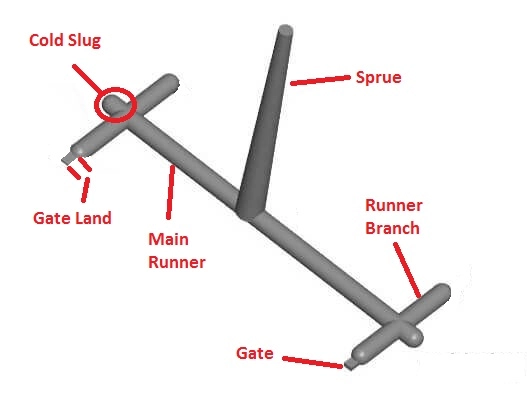

- Sprue: The main path that carries melted plastic from the machine’s nozzle into the mold.

- Runners: A set of paths that move the plastic from the sprue to the gates.

- Gates: Tiny openings that link runners to mold cavities, controlling how plastic fills the part.

What is a Sprue?

The sprue is where melted plastic enters the mold. It’s a cone-shaped channel cut through the mold’s A plate, linking the machine’s nozzle to the runner system. The sprue seals tight to the nozzle with a sprue bushing to stop leaks. Its shape is wider at the mold’s parting line and narrower at the nozzle. This helps the plastic flow smoothly and keeps air from getting trapped, which could cause bubbles or holes in the part.

In single-cavity molds, like for plastic bottles, the sprue might go straight to the cavity. In multi-cavity molds, it connects to runners that spread the plastic to many cavities. After molding, the hardened plastic in the sprue, called “sprue waste,” is usually cut off and thrown away or recycled. It’s not part of the final piece.

Key Points:

- The sprue’s angle and size control how fast and strong the plastic flows.

- Good sprue design cuts waste and fills the mold evenly.

What is a Runner?

Runners are paths that carry melted plastic from the sprue to the gates, which lead to the mold cavities. These channels are cut into one or both halves of the mold where it splits to pop out the parts. Runners are super important for multi-cavity molds. They let one sprue feed lots of cavities, making production faster.

Runner Design Considerations

How runners are made affects the quality and speed of molding. Important things include:

- Length: Short runners use less plastic and speed up the process. But they need to balance so all cavities fill evenly.

- Width: Thin runners fill faster but need more pressure. Wider ones use more plastic but need less pressure.

- Shape:

- Round: Holds pressure best but needs cutting into both mold halves, which is harder to make.

- Parabolic or Trapezoidal: Only needs cutting into one mold half, saving money. But they lose more pressure and waste more plastic.

In multi-cavity molds, runners must fill all cavities at the same time. If runners are different lengths, some parts might not fill right, causing problems like extra plastic (flashing) or incomplete pieces. Engineers might change runner sizes to balance flow, as studies from National Taiwan University show. Even filling makes better parts.

Hot Runner vs. Cold Runner Systems

- Cold Runner: The usual setup where runners aren’t heated. The plastic hardens and must be cut off after molding. These are simpler and cheaper but make more waste and take longer.

- Hot Runner: A fancy system with heated manifolds and nozzles to keep plastic melted. Hot runners cut waste, make better parts, and control temperature and pressure well. But they cost more and are trickier to set up.

What is a Gate?

Gates are the last step in the plastic’s path. They’re small openings that connect runners to mold cavities. By making the path narrow, gates build pressure to fill the cavity fast and evenly, reducing mistakes like sink marks or unfilled parts.

Gate Placement and Design

Where gates go matters a lot. They should be in spots that won’t show trimming marks, like hidden areas. They’re best in thicker parts of the mold to avoid sink marks from uneven cooling. The size and shape of gates affect how fast the plastic flows, the pressure, and the part’s quality.

Types of Gates

Gates come in different types, based on whether they’re in cold or hot runner systems and if they need hand or auto trimming.

Cold Runner Manual Trim Gates

- Edge Gate: A rectangle-shaped gate along the mold’s split line. It’s easy to design and cut off but can cause pressure loss or marks like flow lines.

- Tab Gate: Has a small tab for side-filling, which cuts filling problems but makes trimming harder.

- Fan Gate: A gate that widens toward the cavity, spreading plastic better but leaving bigger trim marks.

- Direct Sprue Gate: Combines the sprue and gate, feeding straight from the nozzle to the cavity. It’s simple but only for single-cavity molds with less flow control.

- Diaphragm Gate: Used for hollow, round parts. It cuts flow marks but is tough to trim cleanly.

Cold Runner Automatic Trim Gates

- Tunnel/Submarine Gate: An angled tunnel that feeds plastic below the split line. It trims itself when the mold opens but is limited by size and can trap gas.

- Cashew Gate: A curved tunnel gate for hidden areas. It trims automatically but can break during removal.

Hot Runner Gates

- Thermal Gate: The usual gate in hot runner systems, guiding plastic from heated nozzles to the cavity.

- Valve Gate: Uses a moving pin to control plastic flow exactly, giving great control in hot runner molds.

Key Takeaways

Sprues, runners, and gates are super important for injection molding. They guide melted plastic from the machine to the mold cavity with care. In simple molds, like direct sprue gate designs, the sprue might be the only part needed. But runners and gates make multi-cavity molds work better. They cut down on mistakes, save plastic, and sometimes trim themselves when parts pop out. Knowing these parts helps factories make molds that save money, make good parts, and work fast. Usually, expert mold designers handle sprue, runner, and gate placement.

FAQ

What is the difference between a sprue and a runner in injection molding?

A sprue is the main path that takes melted plastic from the machine’s nozzle into the mold. Runners are extra paths that spread the plastic from the sprue to the gates, which lead to the mold cavities.

How do hot runner systems differ from cold runner systems?

Hot runner systems use heated manifolds and nozzles to keep plastic melted. They cut waste and make better parts but cost more. Cold runner systems are unheated, simpler, and cheaper but make more waste and may take longer.

Why is gate placement important in injection molding?

Gate placement affects part quality, surface look, and trim marks. Putting gates in thicker or hidden spots cuts down on problems like sink marks and makes parts look cleaner.

What types of gates are automatically trimmed?

Tunnel (submarine) and cashew gates trim themselves when the mold opens. This speeds up work but needs careful design to avoid gas trapping or breaking.

How can runner design impact injection molding efficiency?

Runner length, width, and shape affect waste, speed, and part quality. Short, round runners save plastic and keep pressure. Balanced designs fill multi-cavity molds evenly.

Elevate Your Injection Molding with Silkbridge

Want precise, fast, and reliable injection molding? Team up with a pro like Silkbridge, a Hong Kong-based leader in manufacturing and supply chain help. They offer full services, from making molds and tools to precision molding and quick prototypes. Silkbridge makes high-quality parts for industries like cars, medical tools, and everyday products, meeting global standards.

Check out their products and services, like custom mold making and full supply chain support. Learn about their smart approach and worldwide reach on their About page or explore their special services at Silkbridge Services. Ready to improve your manufacturing? Contact Silkbridge today to talk about your project and get top-notch injection molding solutions. Request a free quote now at contact@silkbridgeltd.com. Or use our WhatsApp link https://wa.me/8618122838771 .