How Does Material Temperature Affect Cold Slug Formation?

The Role of Material Viscosity in Cold Slug Formation

Material viscosity is very important in injection molding. It affects Cold Slug formation. If the material temperature is not controlled well, viscosity can change a lot. High viscosity materials flow poorly. This can cause bad mold filling. It may also lead to Cold Slugs at the nozzle tip. On the other hand, overheated material becomes too runny. It may not hold its shape during injection. Keeping the right temperature helps the material flow smoothly into molds. This prevents leftover Cold Slugs.

Effects of Inconsistent Heating on Material Flow

Uneven heating in the injection molding machine can mess up material flow. This leads to Cold Slug formation. Some parts of the material cool too soon. Others stay melted. This temperature difference can cause incomplete mold filling. It may also cause cooled material to build up at the nozzle or gate. Well-set heaters are needed. Even temperature spread is key to avoiding these problems.

Strategies for Optimizing Material Temperature

To fix Cold Slug issues from bad material temperatures, try these steps:

- Exact Temperature Control: Use advanced controllers to heat materials evenly.

- Warming Materials First: Heat raw materials before putting them in the machine. This keeps melt temperatures steady.

- Regular Upkeep: Check heaters, thermocouples, and other parts often. This lowers risks from uneven heating.

- Checking Melt Flow Index (MFI): Test MFI often. It shows if viscosity adjustments are needed.

Why is Nozzle Design Crucial in Preventing Cold Slugs?

Common Nozzle Design Issues Leading to Cold Slugs

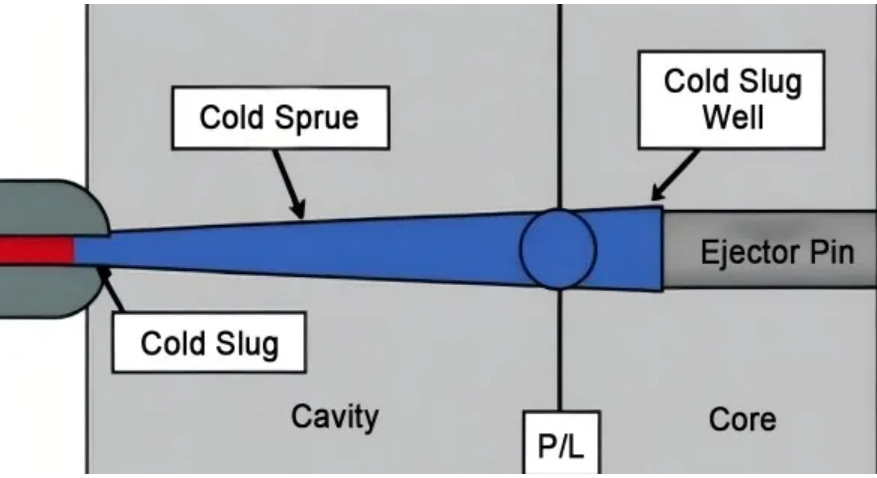

Nozzle design greatly affects Cold Slugs in injection molding. Poorly made nozzles may have spots where material sits and cools. This forms Cold Slugs that block smooth flow in later injections. Also, nozzles with wrong sizes may not keep steady pressure or temperature. This makes Cold Slug problems worse.

The Importance of Proper Nozzle Heating

Good nozzle heating is vital. It keeps a steady melt temperature during the injection cycle. Without enough heat, material near the nozzle tip can harden too soon. This causes blockages or Cold Slugs. Adding strong heating elements around nozzles keeps materials at the right temperature until they reach the mold.

Selecting the Right Nozzle for Specific Applications

Choosing the right nozzle for specific jobs can reduce Cold Slug risks:

- Open Nozzles: These work for materials needing fast flow. But they may need heated sprue bushes to stop cooling.

- Shut-Off Nozzles: These are great for stopping drips. They give exact control over material flow.

- Special Designs: For unique jobs, custom nozzles may be needed. They handle specific issues with material or mold shapes.

How Do Mold Cooling Systems Affect Cold Slug Issues?

The Impact of Uneven Cooling on Mold Performance

Uneven cooling in molds can cause big problems. It leads to Cold Slug formation. When some mold parts cool faster than others, it creates temperature differences. These affect how materials harden and flow. This often causes defects like warping or incomplete filling.

Balancing Cooling Rates to Minimize Defects

Even cooling across all mold parts is key to reducing Cold Slug defects:

- Improved Cooling Channels: Design cooling channels carefully. This ensures even heat spread across molds.

- Thermal Insulation: Use insulating materials around key areas. This prevents fast heat loss and keeps temperatures steady.

- Flow Simulations: Run thermal simulations before production. They find hotspots or uneven cooling areas.

Enhancing Mold Cooling Efficiency

Better mold cooling efficiency shortens cycle times. It also reduces Cold Slug risks:

- High-Conductivity Materials: Use molds made from metals like aluminum. They improve heat transfer.

- Conformal Cooling Channels: Use 3D printing for complex channel shapes. These boost cooling efficiency.

- Active Cooling Systems: Use water or oil-based cooling circuits. They give exact control over mold temperatures.

How Do Process Parameters Impact Cold Slug Development?

Injection Speed and Its Relation to Cold Slugs

Injection speed affects how materials act in injection molding. If the speed is too slow, material may cool too early. This happens before molds are fully filled. It increases Cold Slug risks. However, very fast speeds may cause turbulence or trapped air. This leads to defects.

Pressure Settings and Their Influence on Material Flow

Pressure settings are important for good mold filling. They help avoid Cold Slugs:

- Low Pressure: Not enough pressure can cause incomplete filling. Material may also stall in nozzles.

- High Pressure: Too much pressure can cause flashing or overpacking. But it may push out Cold Slugs if controlled well.

Keeping the right pressure for each material ensures smooth flow. It lowers defect risks.

Cycle Time Optimization to Avoid Defects

Cycle time optimization balances speed and quality. It ensures enough time for filling, packing, and cooling:

- Shorter Cycles: Fast cycles boost output. But they increase risks of poor cooling or early ejection.

- Longer Cycles: Long cycles allow full cooling. But they may slow down production if not watched closely.

By adjusting settings like injection speed, pressure time, and cooling periods, manufacturers get better results. Real-time data from sensors helps. It reduces Cold Slugs and other unwanted issues.

What Material Choices Can Reduce Cold Slug Occurrence?

Characteristics of Materials Prone to Cold Slug Formation

Some materials in injection molding are more likely to form Cold Slugs. High-viscosity materials resist flow. They cool too soon if temperatures are not kept right. This leads to poor mold filling. It also causes hardened material to build up at key spots. Materials with low heat conductivity cool unevenly. This increases Cold Slug risks. Careful selection and handling are needed.

Selecting High-Quality Materials for Consistent Results

Choosing top-quality materials is key to reducing Cold Slug issues. It ensures steady production. High-grade polymers flow better. They also stay stable at high temperatures. This lowers defect chances. Manufacturers should pick materials with even structures and few impurities. These lead to smoother processing. They also reduce cooling issues. Using better raw materials improves product quality. It also cuts waste and rework.

The Role of Additives in Reducing Defect Risks

Additives help change material properties in injection molding. They tackle Cold Slug issues. For example, plasticizers lower viscosity. This improves flow and ensures even mold filling. Heat stabilizers keep material strong at high temperatures. They prevent early cooling near nozzles or gates. Using the right additives tailors material behavior. This meets production needs and reduces defect risks.

How Can I Effectively Tackle Cold Slugs in Production?

Implementing Preventative Maintenance Practices

Preventative maintenance is key to managing Cold Slugs in injection molding. Regular checks and cleaning of nozzles, heaters, and molds ensure good performance. This reduces material buildup or cooling issues. Replacing worn parts quickly helps keep exact temperature control. It also ensures steady material flow.

Regular Monitoring and Adjustments During Production Runs

Constant monitoring of process settings is vital. It catches issues before they become big problems like Cold Slugs. Operators should check temperature, speed, and pressure often. These should match material needs. Making instant adjustments using sensor data prevents uneven heating or poor mold filling.

Leveraging Advanced Technology for Defect Detection

Advanced tools like infrared thermography and CAD simulations help find and fix Cold Slug issues. Infrared thermography shows temperature spread in molds instantly. It spots hotspots or areas cooling too soon. CAD simulations improve mold designs and settings before production. This reduces trial-and-error and boosts efficiency.

Silkbridge Plastic Injection Molding Service

Benefits of Choosing Silkbridge for Your Injection Molding Needs

Silkbridge offers a wide range of injection molding services. They meet various industry needs with accuracy and trust. They use modern equipment and advanced methods. This ensures high-quality results. It also reduces defect risks like Cold Slugs. Their focus on constant improvement and customer happiness makes them a reliable partner. They provide efficient solutions tailored to unique needs.

- WhatsApp: +86 18122838771

- Phone: +86 18122838771

- Email:contact@silkbridgeltd.com