The Need for Micro Injection Molding

The demand for small, high-performing parts is growing. Industries like medical devices, electronics, and cars need better manufacturing methods. Regular injection molding often fails to make very tiny, detailed parts. Micro-molded plastic parts are key to precise engineering. They support fields like healthcare, gadgets, and vehicles. These parts are vital for high-tech uses. Accuracy and dependability are a must. As designs get more complex, tighter limits are needed. Micro injection molding has become a crucial answer.

What Is Micro Injection Molding?

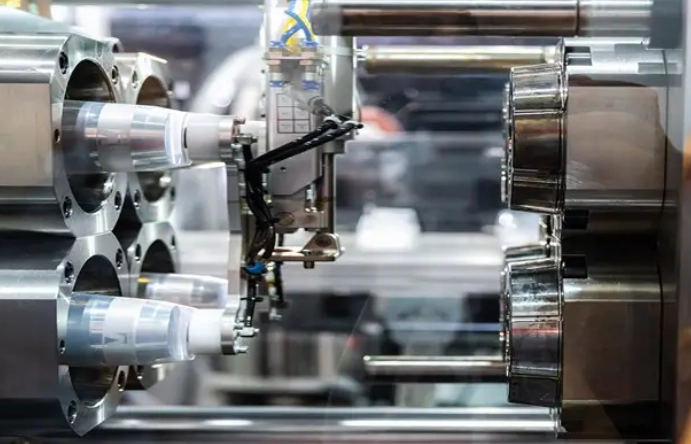

Micro injection molding is a special kind of molding. It focuses on making very small parts. The process creates a mold that matches the part’s shape. Advanced tools like CNC machining and EDM are used. These make molds with super tiny tolerances, down to microns or less. These molds produce parts weighing less than a gram. Their sizes are just a few millimeters.

This method lets makers meet the need for small, exact parts. It also supports large-scale production. It’s great for parts with delicate details, thin walls, or tiny holes. Industries like healthcare and electronics gain a lot. The process makes parts that meet strict rules.

Key Principles of Micro Injection Molding

Micro injection molding depends on several important factors:

- Tiny Size: It focuses on making parts that are naturally small.

- Small Features: Larger parts may have tiny details needing the same accuracy.

- Tight Limits: Precision is key. Tolerances can be as tight as ±0.01 mm.

In the liquid injection molding (LIM) process, materials like liquid silicone rubber are used. They’re injected into heated molds. There, they harden. Direct gating can cut waste by removing runners.

Successful parts with micron limits rely on tooling, mold design, and making. Advanced measuring tools check if parts meet tough industry rules.

Comparing Micromolding to Conventional Injection Molding

Both processes are similar in basics. But key differences set them apart:

- Injection Unit: Micro molding needs special units. They handle tiny shot sizes.

- Accuracy: Micro-molding machines have better control. They inject tiny amounts, like fractions of a gram, accurately.

- Mold Design: Micro molds have smaller cores and cavities. These are made with advanced machining.

- Material Use: High-performance plastics like liquid crystal polymers are common in micro molding. They have great traits.

- Uses: Regular molding fits bigger parts. Micro molding shines for small, complex shapes.

Micro molding needs less clamping force. This allows smaller machines. It makes micro molding cheaper than regular methods for some uses.

Advantages of Micro Injection Molding

- Accuracy and Detail:

This advanced method excels at high accuracy. It handles complex shapes. It ensures steady copying of tricky designs. This is vital in fields like medical devices and gadgets. - Material Options:

The process supports many materials. These include strong plastics known for toughness and heat resistance. - Cost Savings:

Smaller tools cut costs a lot. Micro-molding can cost about 40% less than full-size tooling. - Less Waste:

Methods like direct gating reduce waste. They eliminate runners. - Scalability:

Though focused on small parts, micro injection molding supports big production. It keeps quality high. - Varied Uses:

- Medical: It’s key for making medical tools like catheters and testing devices.

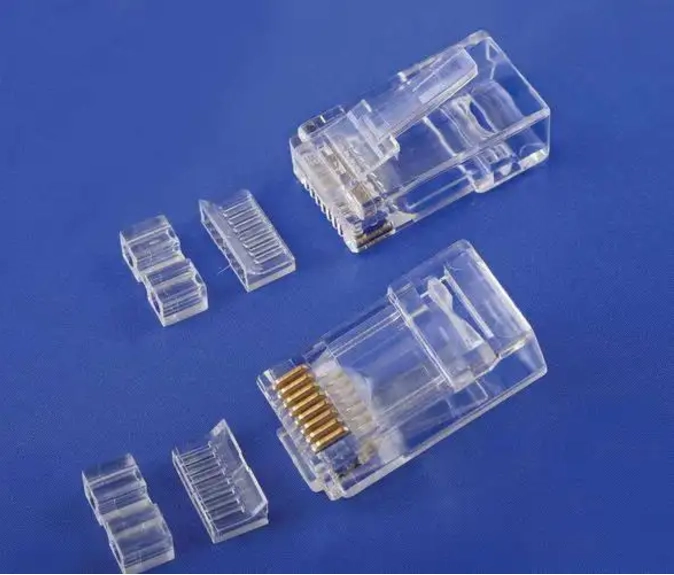

- Electronics: Parts like connectors and tiny optics benefit from this tech.

- Automotive: Light but tough parts for engines or brakes are made efficiently.

By solving issues with regular methods, micro injection molding is vital. It supports innovation at a tiny scale across many fields.

Industries Leveraging Micro Injection Molding Applications

Micro-molded plastic parts are the base of precise engineering. They support industries like medical devices, gadgets, and vehicles. The medical field uses micro injection molding a lot. It makes parts like catheters, surgical tools, and testing devices. These need accuracy and safe materials. This process delivers both.

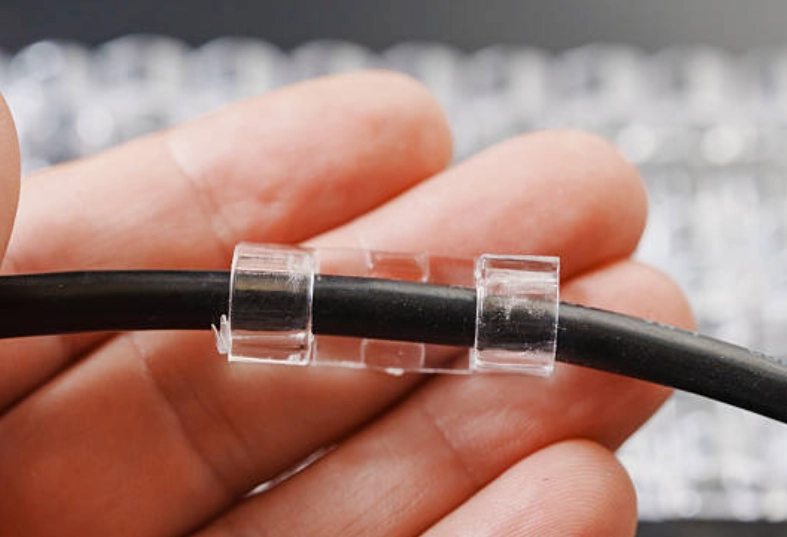

In electronics, tiny connectors and housings are perfect for small gadgets. They ensure function in a small space. Products like smartphones, tiny optics, and communication tools gain from this method’s accuracy and scale.

The car industry uses micro injection molding too. It makes light, tough parts like tiny gears, switches, and engine pieces. These improve vehicle performance. They also cut weight. Aerospace needs small designs with high strength-to-weight ratios. Micro injection molding is key there too.

Beyond these, microfluidic systems in lab-on-a-chip tech are growing. These are used in research and testing. Microfluidic parts, like chips and valves, control fluids precisely.

Challenges Associated with Micro Injection Molding

Micro injection molding offers unmatched accuracy and flexibility. But it has unique challenges. Makers must address these for success.

Tooling and Mold Design Complexity

Great accuracy is vital in mold building and part production. Mold designs must handle alignment issues. They must also manage demolding problems. They need to last for high-volume output. Even small misalignments can ruin the final product.

Material Flow Control

Tiny mold cavities make material flow tricky. Factors like injection speed, pressure, temperature, and gate design need careful control. This prevents defects like short shots or incomplete fills. Balanced pressures in micro molds ensure steady filling.

Quality Control

Checking tiny parts for defects or size accuracy is hard. Their small size makes it tough. Makers often use advanced measuring tools or non-destructive tests. These maintain quality standards.

Scalability

Micro injection molding works well for small runs. But scaling up can use a lot of resources. Designers must check factors like cycle time and machine capacity. This ensures cost-effective big production.

Silkbridge Micro-Molded Parts

Silkbridge is a leader in making ultra-precise micro-molded plastic parts. They serve industries needing small, high-performing solutions. Using advanced micro injection molding tech, Silkbridge makes parts with tolerances as tight as ±0.01 mm.

The company focuses on tough yet light parts. They use high-performance plastics like PEEK and LCP. Their products include tiny gears for precise devices. They also make small medical tools like surgical instruments. Tiny connectors for electronics and custom solutions for special uses are included too.

Silkbridge cares about green practices. They keep material waste low during production. Their skills include over-molding and multi-material blending. This gives clients complete solutions that meet strict industry rules.

- WhatsApp: +86 18122838771

- Phone: +86 18122838771

- Email:contact@silkbridgeltd.com

FAQ

What is micro injection molding?

Micro injection molding is a special kind of molding. It focuses on making very small parts. It uses molds with micron-scale tolerances. These are made with advanced tools like CNC machining.

What industries benefit from micro injection molding?

Medical devices, electronics, cars, aerospace, and research fields use this method. It makes precise, reliable parts.

What materials are used in micro injection molding?

High-performance plastics like PEEK, polycarbonate, and liquid crystal polymers (LCP) are common. Biocompatible materials are used too. They’re strong and heat-resistant.

How does it differ from conventional injection molding?

Micro-molding machines have better control. They inject tiny amounts accurately. They focus on smaller shot sizes and tighter limits than regular methods.

Why choose Silkbridge for micro-molded parts?

Silkbridge uses cutting-edge tech and great skill. They deliver ultra-precise parts tailored to client needs. Their focus on quality ensures steady performance across many uses.