How Does a Plastic Injection Molding Machine Work

What Is an Injection Molding Machine A plastic injection molding machine is the key tool for injection molding. It changes raw plastic pellets into many different products. This amazing piece of modern technology combines heat and pressure. It shapes plastics into forms ranging from simple bottle tops to complex car parts. The heart of […]

What Is Micro Injection Molding? An In-Depth Overview

The Need for Micro Injection Molding The demand for small, high-performing parts is growing. Industries like medical devices, electronics, and cars need better manufacturing methods. Regular injection molding often fails to make very tiny, detailed parts. Micro-molded plastic parts are key to precise engineering. They support fields like healthcare, gadgets, and vehicles. These parts are […]

Comparing Two-Shot, Multi-Shot Molding with Overmolding for Plastic Parts

What is Plastic Injection Molding Plastic injection molding is a common way to make plastic parts. It involves pouring melted plastic into a mold. The plastic cools and hardens to match the mold’s shape. This method is great for making many identical, detailed parts with exact sizes. It works with different types of thermoplastics. This lets […]

Translucent and Clear Plastic Injection-Molded Parts

Materials Options for Translucent and Clear Injection Molding Acrylic (PMMA) Acrylic can be molded into very clear and colored plastic items. It is safe, resists scratches, and blocks UV rays. This makes it a top pick for outdoor gear. Acrylic accepts dyes well. This suits it for lenses, lights, and items needing sharp visuals. However, […]

TPU vs. TPE: Understanding the Nuances of Injection Mold Materials

Overview of TPU and TPE What is TPU (Thermoplastic Polyurethane)? Thermoplastic Polyurethane, or TPU, is a handy material that mixes traits of plastic and rubber. It’s known for being super strong, stretchy, and tough against scratches and chemicals. TPU has been a go-to choice in many fields since BF Goodrich created it in 1959. You’ll […]

ABS vs. Polypropylene (PP): Choosing Between Two Popular Plastics

Getting to Know ABS and Polypropylene (PP) What Makes ABS Special ABS, or Acrylonitrile Butadiene Styrene, is a plastic made from three parts: acrylonitrile, butadiene, and styrene. It’s super strong, stiff, and can take a hit without breaking. ABS can handle okay heat without bending, melting at about 105°C (221°F). It fights off rust well […]

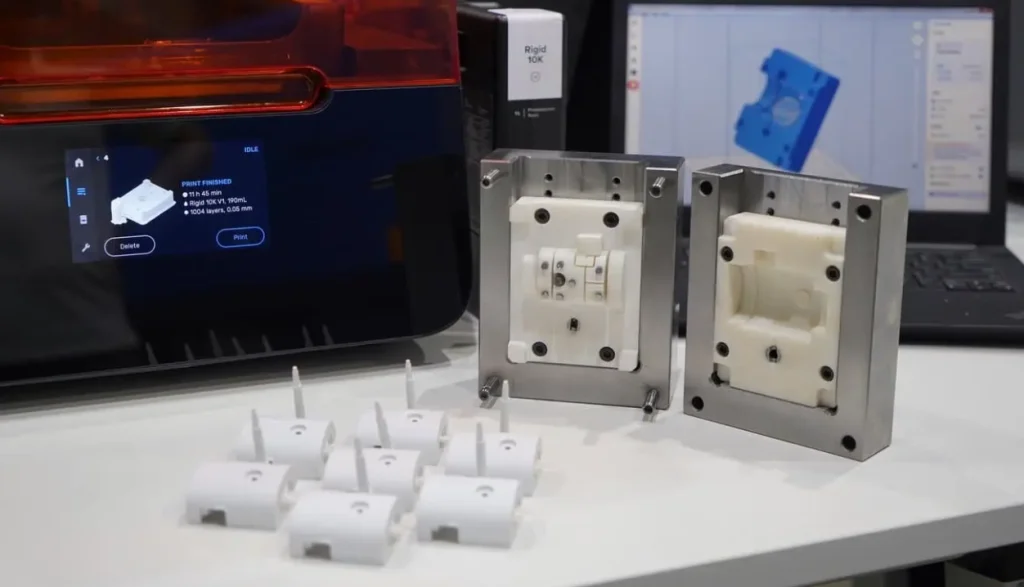

Low-Volume Injection Molding: Suit Your Small Batch Order

On-Demand Manufacturing in Injection Molding The Concept of On-Demand Manufacturing On-demand manufacturing is a game-changing method in the production world. Products are made only when needed. This avoids mass production and storage. It fits perfectly with Low-Volume Injection Molding. Businesses can quickly meet market needs. They avoid overproduction or extra stock. By using this approach, companies […]

What Are the Causes of Cold Slug in Injection Molding?

How Does Material Temperature Affect Cold Slug Formation? The Role of Material Viscosity in Cold Slug Formation Material viscosity is very important in injection molding. It affects Cold Slug formation. If the material temperature is not controlled well, viscosity can change a lot. High viscosity materials flow poorly. This can cause bad mold filling. It […]

Mastering New Product Development in Consumer Electronics for 2025

Understanding Consumer Electronics New Product Development Key Trends Shaping Electronics Product Development in 2025 The consumer electronics world is changing quickly. New ideas drive this change. In 2025, trends like adding artificial intelligence, using green materials, and better connections shape electronics product development. These trends make devices work better. They also meet people’s wishes for smarter, earth-friendly […]

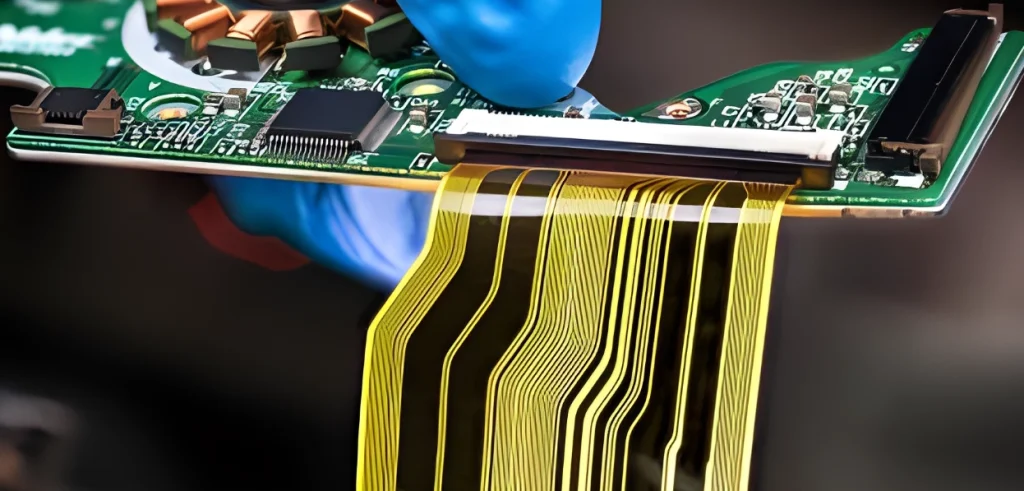

Flex Rigid PCB Design Guidelines for High Reliability

Stack-Up and Core Material Selection Picking the correct materials is vital in flex rigid PCB design. Usually, the rigid parts use FR4, while the flexible sections depend on polyimide (PI) because of its heat resistance and ability to bend. Adhesive-less PI films are favored for very reliable uses. A balanced layer stack-up stops bending or strain. […]