How is Plastic Injection Molding Revolutionizing Modern Furniture?

What is Injection Molding for Modern Furniture Design? Injection molding is a key way to make modern furniture. It shapes materials using a mold. For plastic injection molding furniture, this means heating plastic until it’s soft and pushing it into a mold. Once it cools, the plastic hardens into the right shape. This method lets […]

Plastic Injection Molding Toy Manufacturing

Understanding the Plastic Toy Injection Molding Plastic toy injection molding is a popular way to make toys. It’s used a lot because it can create tricky shapes with clear details and steady quality. Plastic toys are a big part of the toy world. They’re loved for their variety, toughness, and low cost. The process melts plastic […]

Common Plastic Materials for Injection Molding

The Top 10 Plastic Injection Molding Materials Plastic materials for injection molding are used in lots of industries. They’re liked because they’re bendy, strong, and cheap. These plastics vary in how tough they are, how they resist chemicals, how clear they look, and how simple they are to shape. Choosing the right plastic is super […]

7 Common Injection Molding Defects and How to Avoid Them

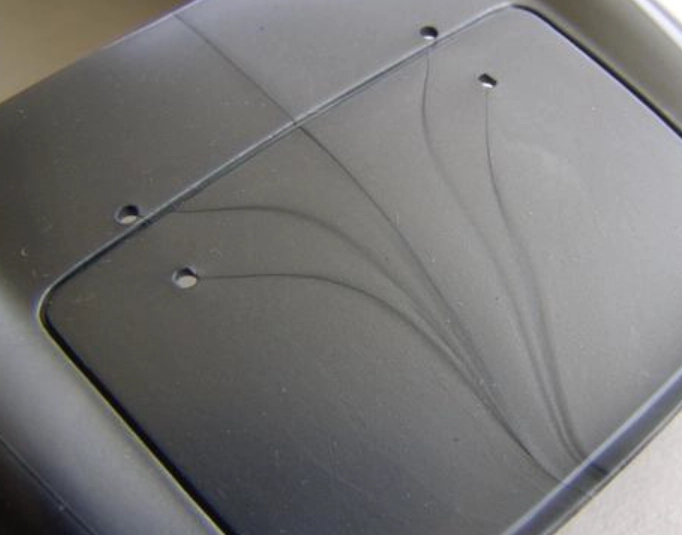

Flow Lines Flow lines are streaks or odd-colored patterns on a part’s surface. They happen when molten plastic moves at different speeds in the mold. This causes the plastic to harden unevenly. It looks bad and may show problems in the molding process. It often means the injection speed or pressure is too low. To […]

Glass Transition Temperature of Polymers

Glass Transition Temperature of Polymers What is Glass Transition Temperature (Tg)? The glass transition temperature (Tg) is a super important feature of polymers. It shows the temperature where an amorphous polymer changes. It goes from hard and stiff to soft and bendy. This change isn’t about melting crystals. It’s about how polymer chains move. Below […]

HDPE Plastic Injection Molding

What is High-Density Polyethylene (HDPE)? High-Density Polyethylene (HDPE) is a common plastic. It’s super strong and tough. It resists bumps and blocks water well. HDPE is cheap and easy to shape with injection molding. That’s why it’s used a lot in factories, cars, and everyday items. It comes from oil and has a simple structure. […]

How Does a Plastic Injection Molding Machine Work

What Is an Injection Molding Machine A plastic injection molding machine is the key tool for injection molding. It changes raw plastic pellets into many different products. This amazing piece of modern technology combines heat and pressure. It shapes plastics into forms ranging from simple bottle tops to complex car parts. The heart of […]

What Is Micro Injection Molding? An In-Depth Overview

The Need for Micro Injection Molding The demand for small, high-performing parts is growing. Industries like medical devices, electronics, and cars need better manufacturing methods. Regular injection molding often fails to make very tiny, detailed parts. Micro-molded plastic parts are key to precise engineering. They support fields like healthcare, gadgets, and vehicles. These parts are […]

Comparing Two-Shot, Multi-Shot Molding with Overmolding for Plastic Parts

What is Plastic Injection Molding Plastic injection molding is a common way to make plastic parts. It involves pouring melted plastic into a mold. The plastic cools and hardens to match the mold’s shape. This method is great for making many identical, detailed parts with exact sizes. It works with different types of thermoplastics. This lets […]

Translucent and Clear Plastic Injection-Molded Parts

Materials Options for Translucent and Clear Injection Molding Acrylic (PMMA) Acrylic can be molded into very clear and colored plastic items. It is safe, resists scratches, and blocks UV rays. This makes it a top pick for outdoor gear. Acrylic accepts dyes well. This suits it for lenses, lights, and items needing sharp visuals. However, […]