The smart hardware ODM market is growing rapidly, projected to reach $100 billion by 2030, growing at a CAGR of 10.5%. Increasing demand for innovative and connected devices drives this growth. However, intense competition and shifting technological environments are major challenges to deal with for companies. Partnering with an ODM is strategic, but knowing these challenges and using effective solutions will be critical to a successful product launch.

Understanding ODM in Consumer Electronics

An ODM will develop product design based on specification provided by companies or already prepared solutions, of which only customization or re-branding is feasible. Unlike OEMs that do strict external design specifications, extended services are given by ODMs in aspects such as: product specification, system design, supplier selection, mechanical design, design validation and electronic manufacturing. This will make companies bring into the market swiftly without huge R&D and investment in production facilities.

Key Challenges in ODM Consumer Electronics Projects

1. Rapid Technological Advancements

The industry of consumer electronics is one of the most fast-moving sectors, with continuous innovation in smart devices, integration of AI, augmented and virtual reality, wearable technology, 5G connectivity, and display technologies. And ODMs have to innovate continuously in order for them to be relevant, with the twin challenge of moving with emerging trends and maintaining cost-effective production.

2. Supply Chain Vulnerabilities

Global supply chain disruptions, influenced by pandemics and geopolitical tension, have increased the complexity associated with sourcing raw materials and adhering to production schedules. Shortages of critical components, along with an increase in costs, might cause delays to projects and increases in production expenses. ODMs must, therefore, manage risks proactively for smooth operation.

3. Competitive Pricing Pressures

The consumer electronics market is highly competitive, and the brands are striving to minimize costs while maintaining product quality. Hence, ODMs operate within tight profit margins. Cost reduction balanced with quality assurance is an ongoing challenge that requires process optimization and strategic sourcing.

4. Intellectual Property (IP) Risks

Today’s hot issues faced by the ODM industry continue to be related to IP theft and patent infringement. The designs and proprietary technologies may be in danger of unauthorized replication, bringing about financial loss and damage to brand reputation. Ensuring effective IP protection for maintaining competitive advantages is critical.

5. Software and Hardware Integration Complexities

Fundamental to the functionality of smart consumer electronics is software and hardware in seamless interaction. On the other hand, such complex system integration requires highly specialized expertise, stringent testing, and cross-disciplinary collaboration among the engineering teams.

6. Regulatory Compliance

Products of consumer electronics have to adhere to various international regulations touching on safety, environmental concerns, and quality standards. This may require continuous monitoring of regulatory changes and stringently adhering to compliance requirements, which is resource-intensive but key to market access and brand credibility.

7. Short Product Life Cycles

Consumer electronics also face rapid obsolescence rates with changing consumer interests and formidable advances in technology. Frequent product updates and redesigns are thus necessary to keep up with the market demand. Efficient product life cycle management would help optimize investments and waste.

8. Labor Shortages

Labor shortages have taken hold throughout manufacturing due to the changing demographic environment and overall declining interest in the skilled trades. Inability to find skilled labor may impact production efficiency and operational risks. For smooth operation, companies must adapt to this challenge of a scarce labor pool in some manner.

Strategies to Overcome Challenges

1. Embrace Agility and Innovation

Being responsive to technological trends enables ODMs to invest in research and development. Agile product development methodologies and flexible manufacturing systems facilitate quick adaptation to changes within the marketplace, which shortens the time to market for new products.

2. Strengthen Supply Chain Resilience

ODMs have to reduce supply chain risks by diversification, advanced inventory management, and real-time tracking technologies. Supply chains will be more stable and cost-efficient with strategic sourcing and localized production.

3. Optimize Costs Without Compromising Quality

Efficient production techniques, automation, and value engineering will contribute to cost reduction without compromising product standards. Investment in advanced manufacturing technologies will enhance efficiency and ensure long-term profitability.

4. Implement Robust IP Protection

The ODMs must establish solid legal agreements, secure communication channels, and patent strategies to safeguard proprietary designs. This helps to create trust between partners and reduces the chances of future legal conflicts.

5. Enhance Software and Hardware Integration

Specialized engineering teams in concert with advanced design tools and robust testing protocols ensure that software and hardware are integrated smoothly. Reliable system performance ensures premium quality consumer electronics.

6. Ensure Regulatory Compliance

By monitoring regulatory requirements and investing in compliance initiatives with expert consultations, ODMs will be able to address global standards. Proactive compliance management avoids expensive penalties and enhances brand reputation.

7. Proactive Product Life Cycle Management

Efficient product life cycle management is supported by agile development methodologies, responsive market research, and sustainable manufacturing practices. Recyclable materials and modular design principles might help extend the lives of products with very limited environmental degradation.

8. Address Labor Shortages Through Training and Automation

Professional training for the workforce and innovative recruitment methods can overcome the labor shortage. Additionally, with the integration of automation and robotics, production processes tend to be less dependent on labor, which in turn increases operational efficiency.

Silkbridge: A Comprehensive ODM Partner

Silkbridge merges British innovation with Chinese efficiency in manufacturing. It provides a full-service ODM solution for consumer electronics brands. The expertise of Silkbridge encompasses:

Product Design and Development: Electronic, mechanical, and plastic injection mold design to achieve maximum performance.

Plastic Injection Molding: High-precision mold making for various material applications, including medical-grade components.

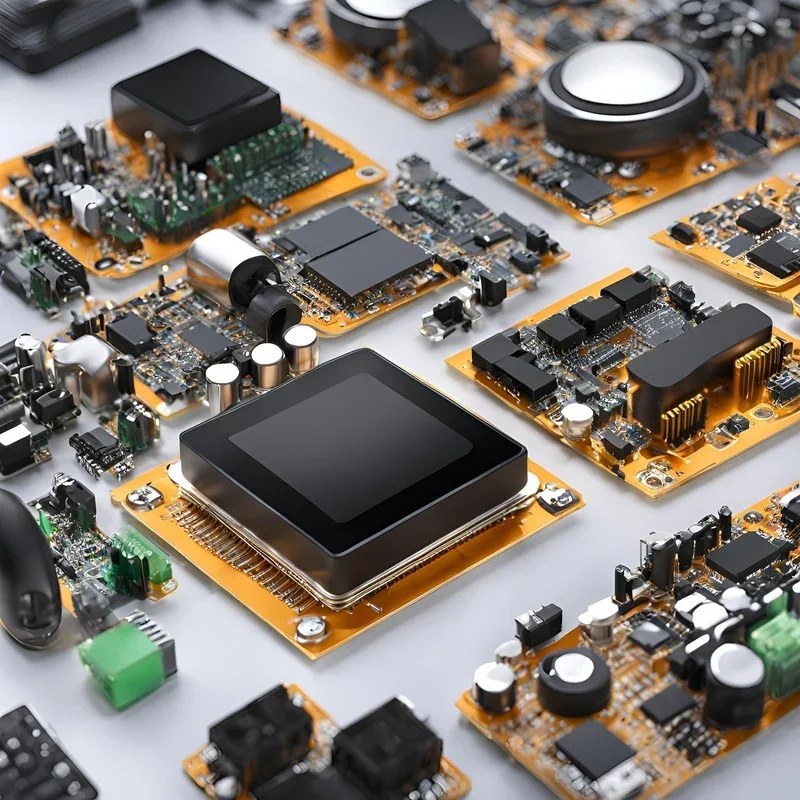

PCB Development and Manufacturing: In-house R&D supported by automated SMT lines enables high-quality production of PCBs.

Electronic Product Assembly: All-inclusive assembling and packaging solution in controlled environment conditions.

Distribution Services: DDP shipping – customs clearance and tax compliance arrangement.

ISO 9001-accredited, Silkbridge focuses on quality and efficiency to provide value to customers in very diversified vertical markets, such as consumer electronics, medical devices, and industrial applications.

Conclusion

The challenges faced by ODM consumer electronics projects are technological advancement, supply chain disruption, competitive pricing, IP risks, integration of software and hardware, regulatory compliance, short product life cycles, and labor shortages. Companies can try to overcome these challenges by adopting proactive strategies such as supply chain diversification, process optimization, regulatory compliance management, and leveraging emerging technologies like augmented reality. In this respect, collaboration with an experienced ODM like Silkbridge would definitely assure access to end-to-end solutions for product innovation, enhancement of operational efficiency, and securing long-term market success.

To learn more about the consumer electronics ODM services available from Silkbridge, reach out to their team at contact@silkbridgeltd.com. Or our whatsapp link https://wa.me/8618122838771